Flexible quanta polymer white light EL part and its making method

A quantum dot polymer and luminescent technology, which is applied in the manufacture of electroluminescent light sources, electric solid devices, semiconductor/solid devices, etc., can solve the problems of high cost, difficult to master, and complicated preparation process, and achieve high contrast and brightness , improved working life and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

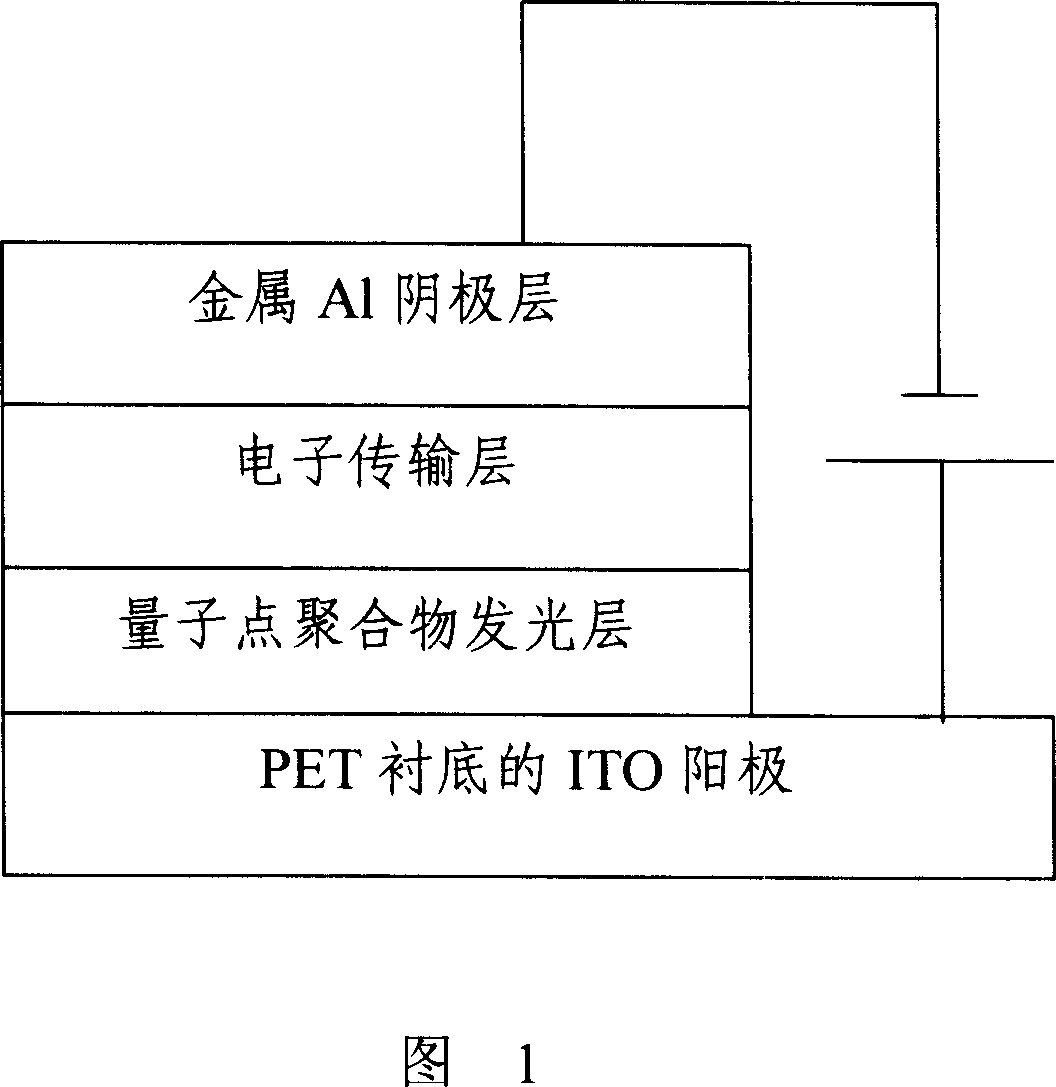

[0020] (1) The ITO anode etched into a 5mm*60mm strip-shaped PET substrate was repeatedly cleaned in a detergent, then soaked in isopropanol, acetone and chloroform solutions and ultrasonically cleaned, and finally dried in an infrared oven for use ;

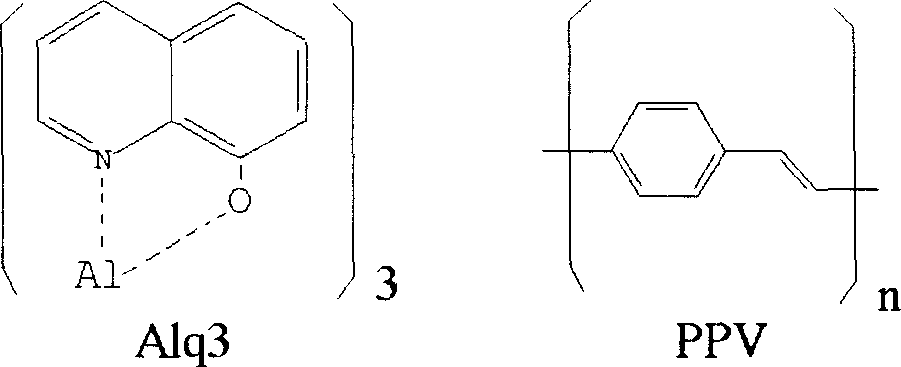

[0021] (2) Dissolve ZnS quantum dots and polymer PPV in a mass ratio of 2:1 in chloroform solution of 1 to 2 mg / ml, and form a film by spin coating; low speed 1100rpm, film formation time 20s, high speed 3000rpm , the film forming time is 30s, and put it in the desiccator for 10 hours after completion;

[0022] (3) Alq3 is pressed into sheets, and a film is formed on the light-emitting layer by vacuum evaporation to form an electron transport layer. The condition is: the degree of vacuum is greater than 8×10 -4 Pa, the evaporation current is about 5A, and the evaporation time is 15 minutes;

[0023] (4) The preparation of the Al cathode adopts the Al wire with a length of about 2 cm on the tungsten alloy furnace wire, and with...

Embodiment 2

[0027] (1) The ITO anode etched into a 5mm*50mm strip-shaped PET substrate was repeatedly cleaned in a detergent, then soaked in isopropanol, acetone and chloroform solutions and ultrasonically cleaned, and finally dried in an infrared oven for use ;

[0028] (2) Dissolve ZnS quantum dots and polymer PPV in a mass ratio of 2:1 in chloroform solution of 1 to 2 mg / ml, and form a film by spin coating method; low speed 1300rpm, film forming time 20s, high speed 3000rpm, film forming time 30s, put it in the desiccator for 8 hours after completion;

[0029] (3) Dissolve PBD in a 1.6mg / ml chloroform solution, and form a film by spin coating; low speed 1000rpm, film formation time 18s, high speed 3000rpm, film formation time 25s, and place it in a desiccator for 6 Hour;

[0030] (4) The preparation of the Al cathode adopts the Al wire with a length of about 2 cm on the tungsten alloy furnace wire, and with the help of a strip mask plate, a thin layer of strip-shaped Al is vacuum-dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com