Linear temperature sensor

A line type and component technology, applied in the field of line type temperature sensing components, can solve problems such as waste, short circuit, fault alarm signal sent by the conversion box by mistake, and achieve the effect of avoiding waste and preventing false alarm problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

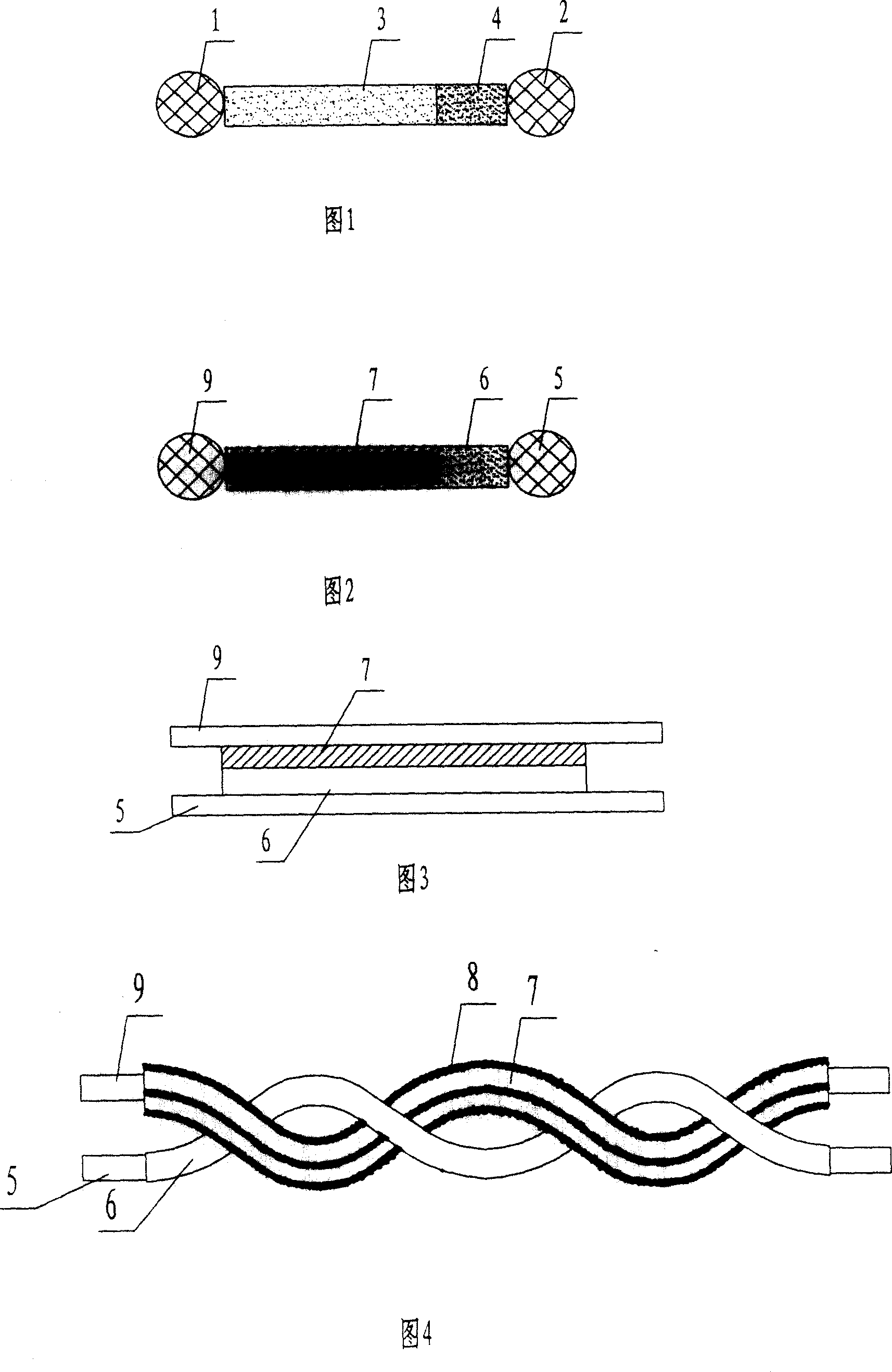

[0021] The linear temperature sensing element provided by the present invention will be described in detail below with reference to the drawings and embodiments.

[0022] As shown in Figure 2, the linear temperature sensing element provided by the present invention comprises two detection conductors 5, 9 arranged in parallel and a meltable insulation layer 6 arranged in parallel between the detection conductors 5, 9 and made of NTC characteristic material and high The combined layer 7 is composed of insulating materials with softening points distributed at intervals. The detection conductors 5, 9 can be hollow wires, solid wires or metal fiber braided wires, and the parallel arrangement includes several ways of parallel, winding and coaxial arrangement. As shown in FIG. 3 , when the two detection conductors 5 and 9 are arranged in parallel, the meltable insulating layer 6 and the combined layer 7 are arranged in parallel between the detection conductors 5 and 9 and adhere to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com