Integral engine multiple utility assembly for an automotive vehicle

A one-piece, engine technology, applied in the direction of the arrangement, application, and power unit of the cooling combination of the power unit, which can solve the problems of limiting the volume and weakening the utility of the assembly package, etc., and achieve the effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

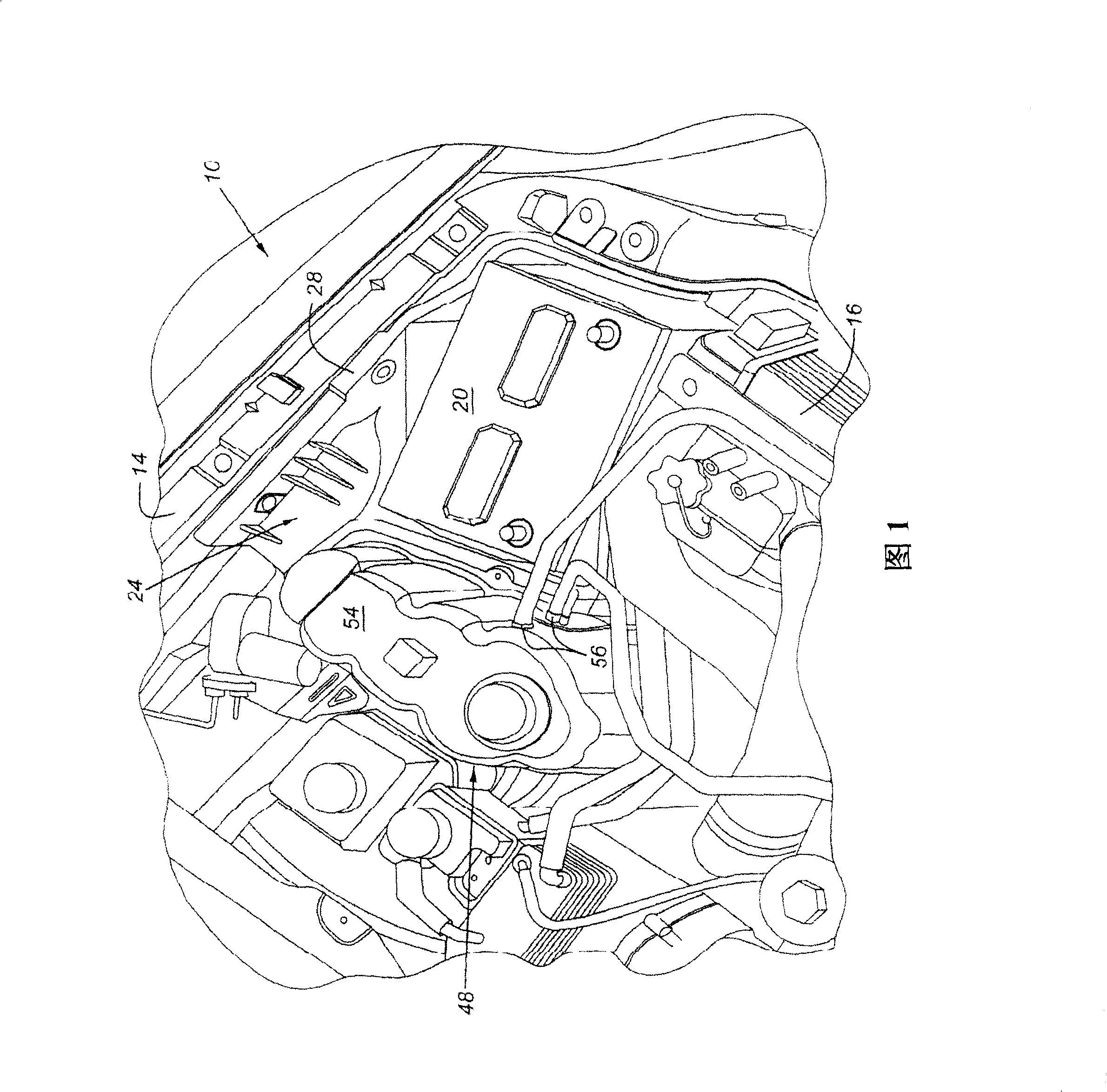

[0014] Such as figure 1 As shown, the vehicle engine compartment 10 includes a one-piece assembly 24 that is at least partially mounted to the fender 14 or another structure adjacent to the engine compartment 10 . The battery 20 is carried in the integrated assembly 24, and the integrated assembly also includes a coolant storage tank 48 and a vacuum storage tank 60 ( figure 1 not shown).

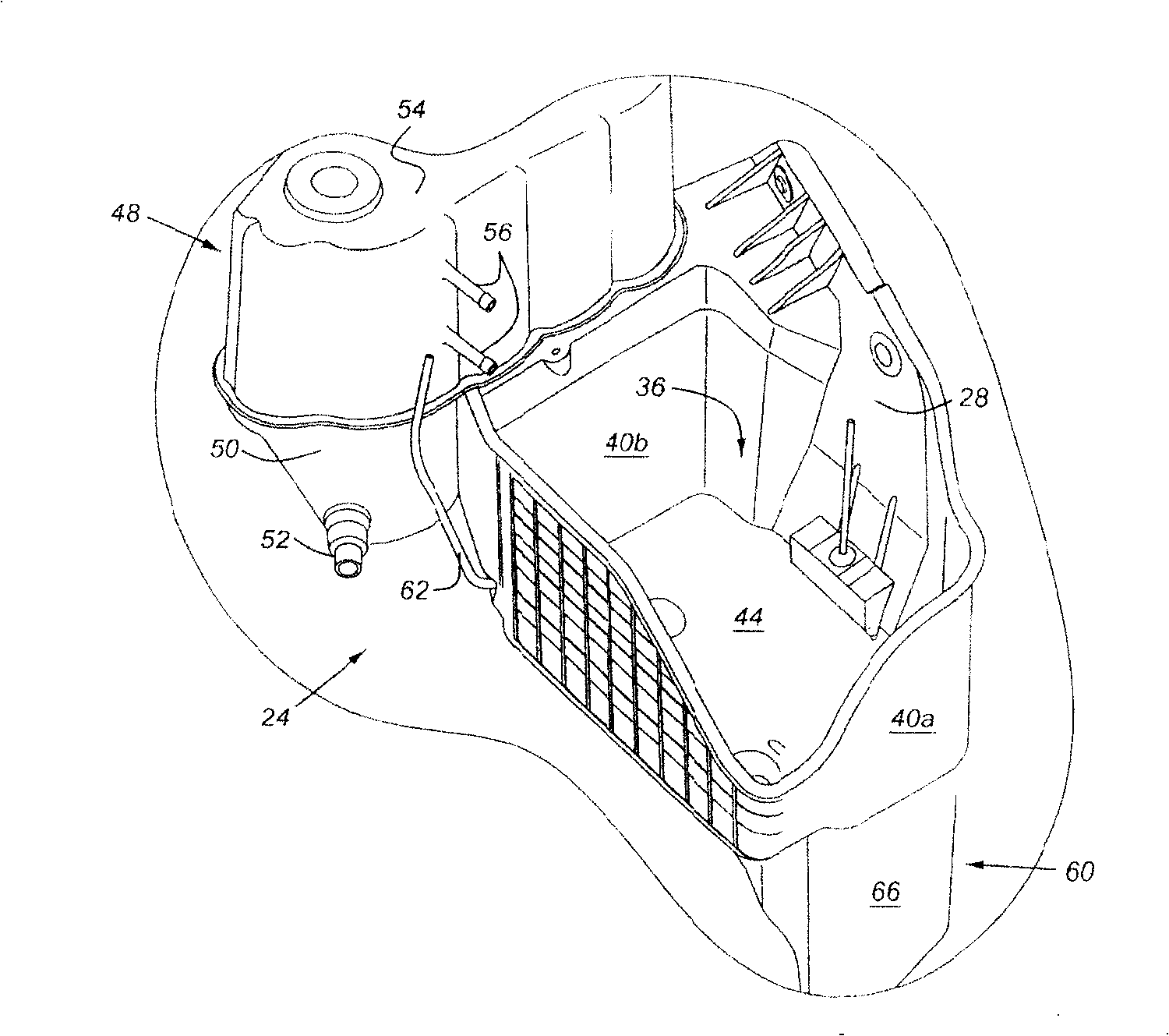

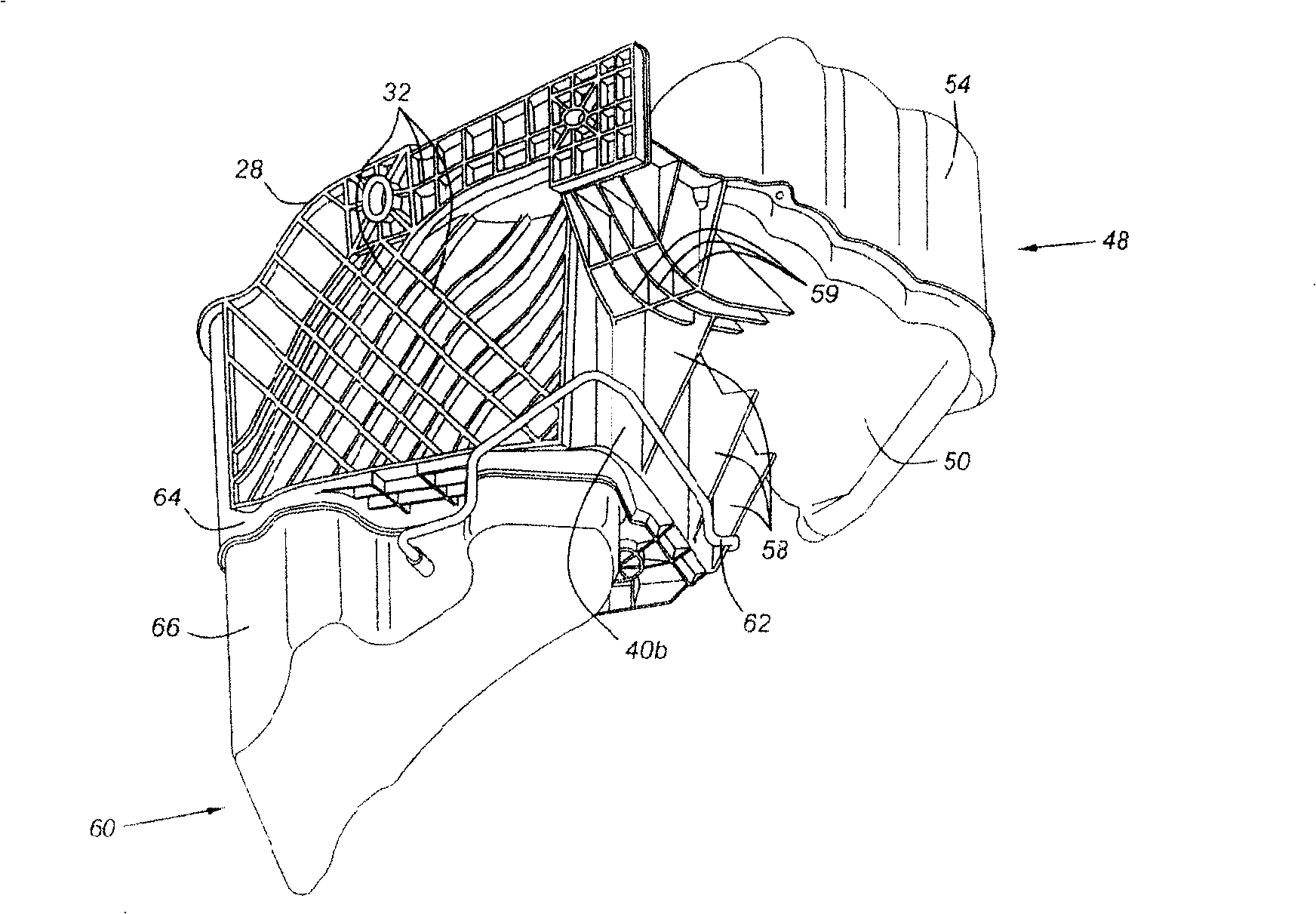

[0015] figure 2 One-piece assembly 24 is shown in which battery 20 is not secured. Mounting plate 28 mounts to fender 14 or to twin-tube tubing (not shown) of another structure, such as a frame, which may include a hydroformed tube assembly. The mounting plate 28 is reinforced by a series of integrated ribs 32 (such as image 3 shown). This gives the mounting plate 28 sufficient strength to function as a single fixture for the one-piece assembly 24 . This makes the task of securing the one-piece assembly a simpler task than would otherwise be the case requiring other securing points. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com