Elastic structure link rod connected type tyre

A structural and connecting technology, applied to tire parts, wheels, non-pneumatic tires, etc., can solve problems such as high temperature heat accumulation, serious accidents, rubber aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

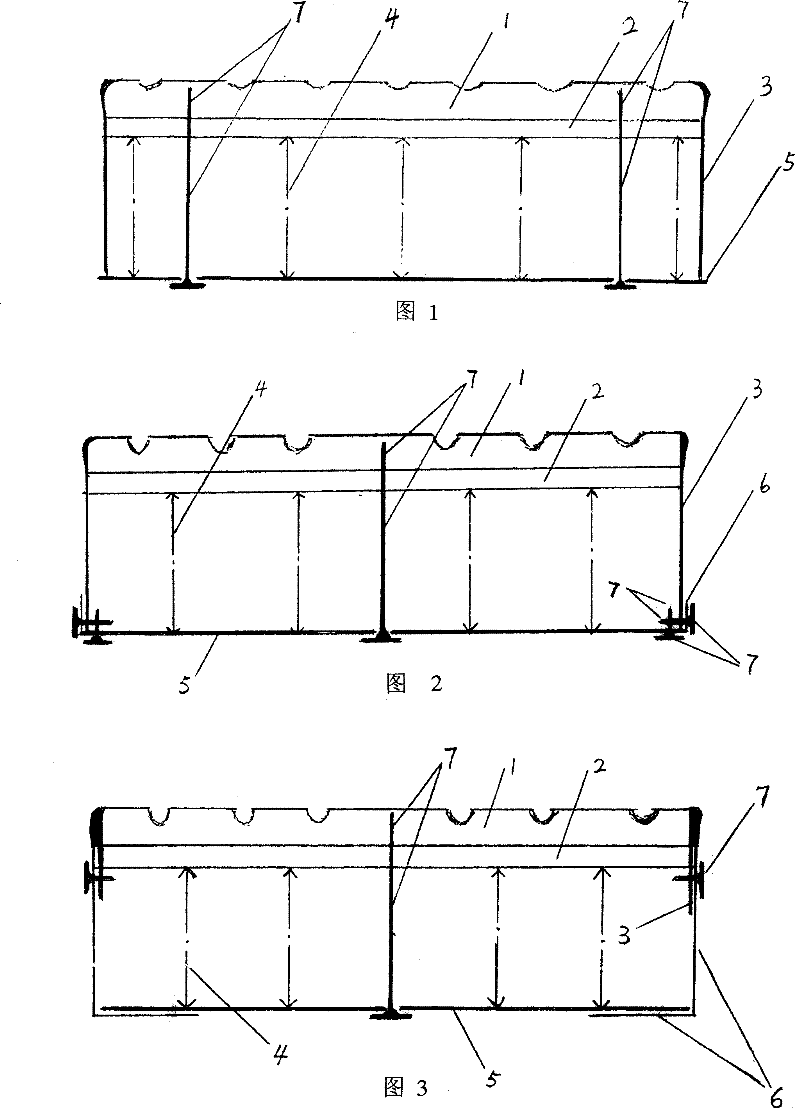

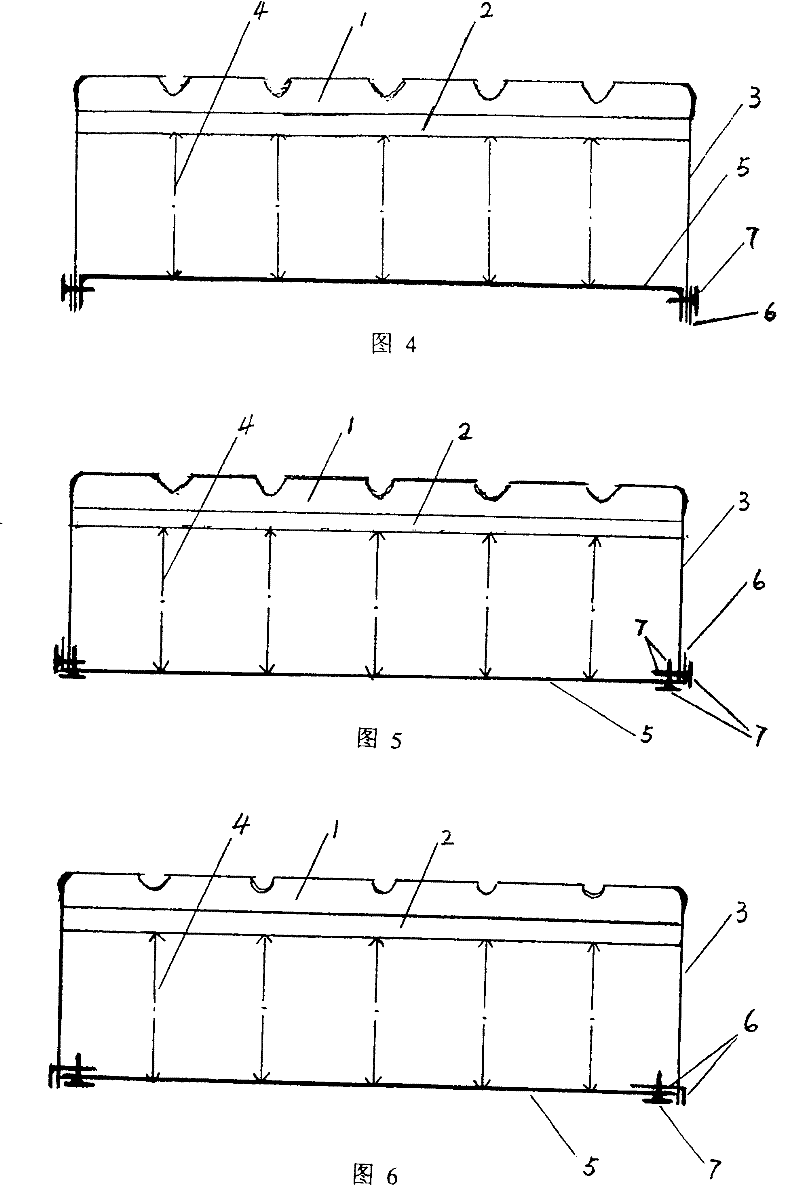

[0093] Example 1, elastic structure connecting rod-connected tire (specification 205 / 33 / 19. In the formula, 205 represents the tire section width; 33 represents the aspect ratio, that is, the ratio of the section height H to the section width B; 19 represents the rim diameter, unit inches).

[0094] refer to figure 1 : The tire is set on the rim 5 and consists of a tread shoulder layer 1 , a tire base layer 2 , a sidewall layer 3 and a rim 5 . The diameter of the tire is about 615mm; the width of the tire section is about 205mm. The tread shoulder layer 1 is located at the crown of the tire, and is composed of natural rubber or synthetic rubber, with a thickness of about 9-10 mm, and the tread is engraved with patterns. The tread base layer 2 has a thickness of about 7 mm and a width of about 205 mm, and is fixed on the inner surface of the tread layer. Both sides of the tire base layer 2 are connected with the upper part of the sidewall layer 3, and the lower part of the ...

Embodiment 2

[0099] Example 2, refer to figure 2 : (Specification 205 / 28 / 19)

[0100] The tread shoulder layer 1, the tire base layer 2, the sidewall layer 3, the rim 5, and the connecting rod 7 are basically the same as those in the embodiment 1, but have the following differences: the lower part of the sidewall layer 3 is equidistantly made with holes; the circumferential surface of the rim 5 There are three rows of equidistant holes on the center line and the equidistant circumference on both sides of the connecting rod, 16 in each row, and the diameter of the holes is about 8mm-18mm; the diameter of the other connecting rod 7 is 7-11mm, and the length is 30-45mm.

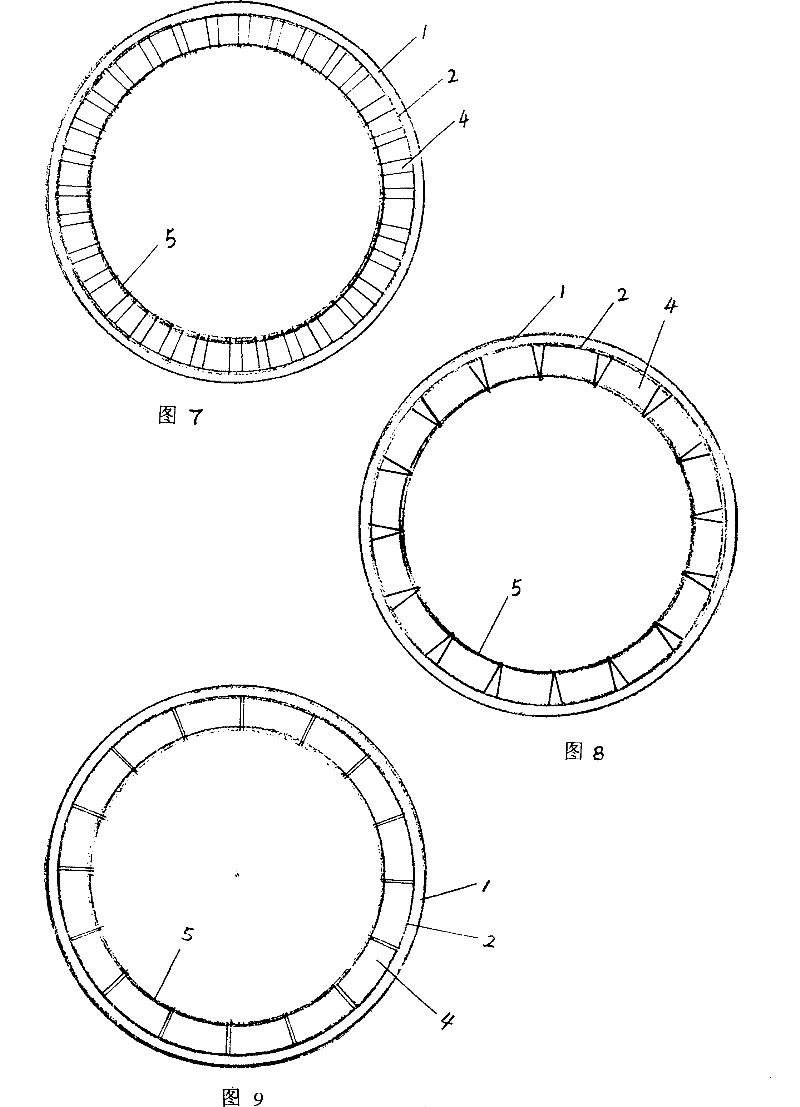

[0101] The elastic structure 4 is composed of a plurality of hollow cylinders arranged and combined (refer to Figure 8 and Figure 11 ), one end of the elastic structure 4 is extruded (or called "closely") on the bottom surface of the tire base 2, and the other end is extruded (or "closed") on the crown surface of the ri...

Embodiment 3

[0103] Example 3 (refer to image 3 ): Specifications 205 / 28 / 19

[0104] The tread shoulder layer 1, the tire base layer 2, the sidewall layer 3, the rim 5, and the connecting rod 7 are basically the same as those in Example 1, but have the following differences:

[0105] The sidewall layer is short, about 25mm; there are about 20 screw holes with a diameter of about 17mm (such as image 3 , Figure 16 ).

[0106] The elastic structure 4 is composed of a plurality of hollow truncated cones arranged and combined (refer to Figure 9 and Figure 12 ), one end of the elastic structure 4 is fixed with the bottom surface of the tire base layer 2, and the other end is pressed (or called "closely") on the crown surface of the rim 5, and can move relatively.

[0107] The upper part of the sidewall layer 3 is connected with the tire base layer 2, and the frame guard 6 has an inward flange. The connecting rod 7 passes through the holes on the frame guard 6 from the side and is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com