Automatic spray printing and synchronous detection and tracking device and its method

A technology for synchronous detection and tracking of devices, applied in printing devices, printing, instruments, etc., can solve problems such as the inability to re-print barcodes, barcode heat curing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

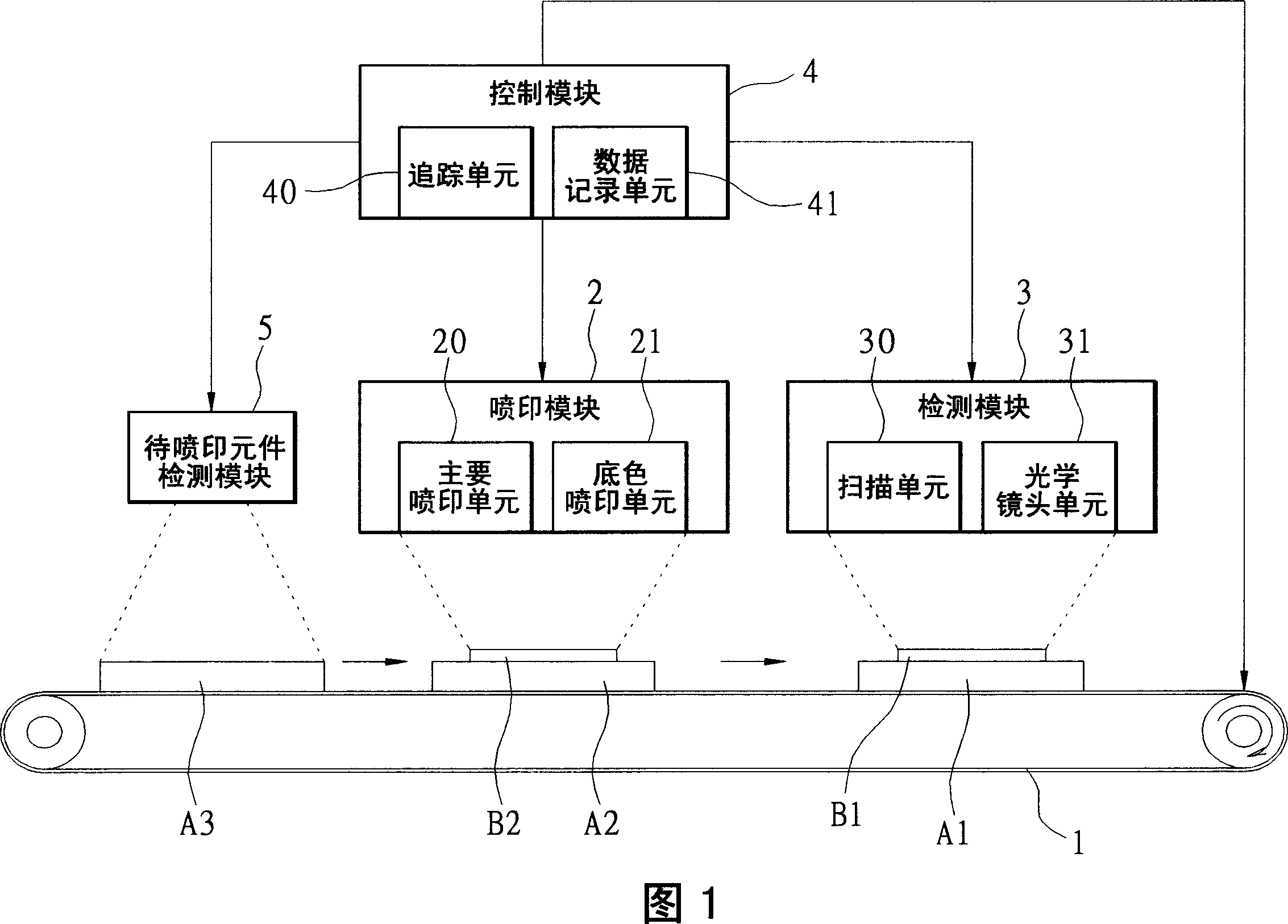

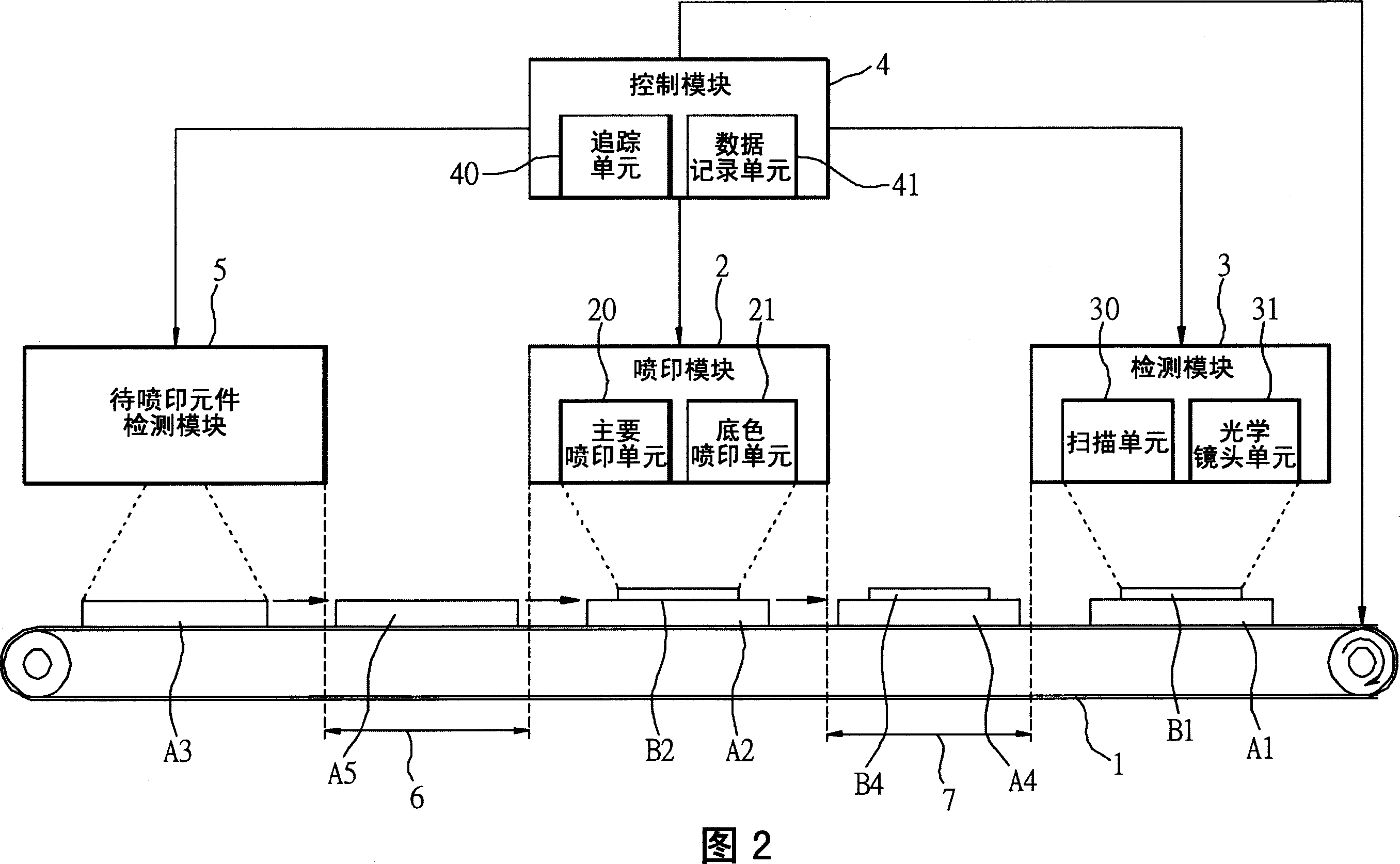

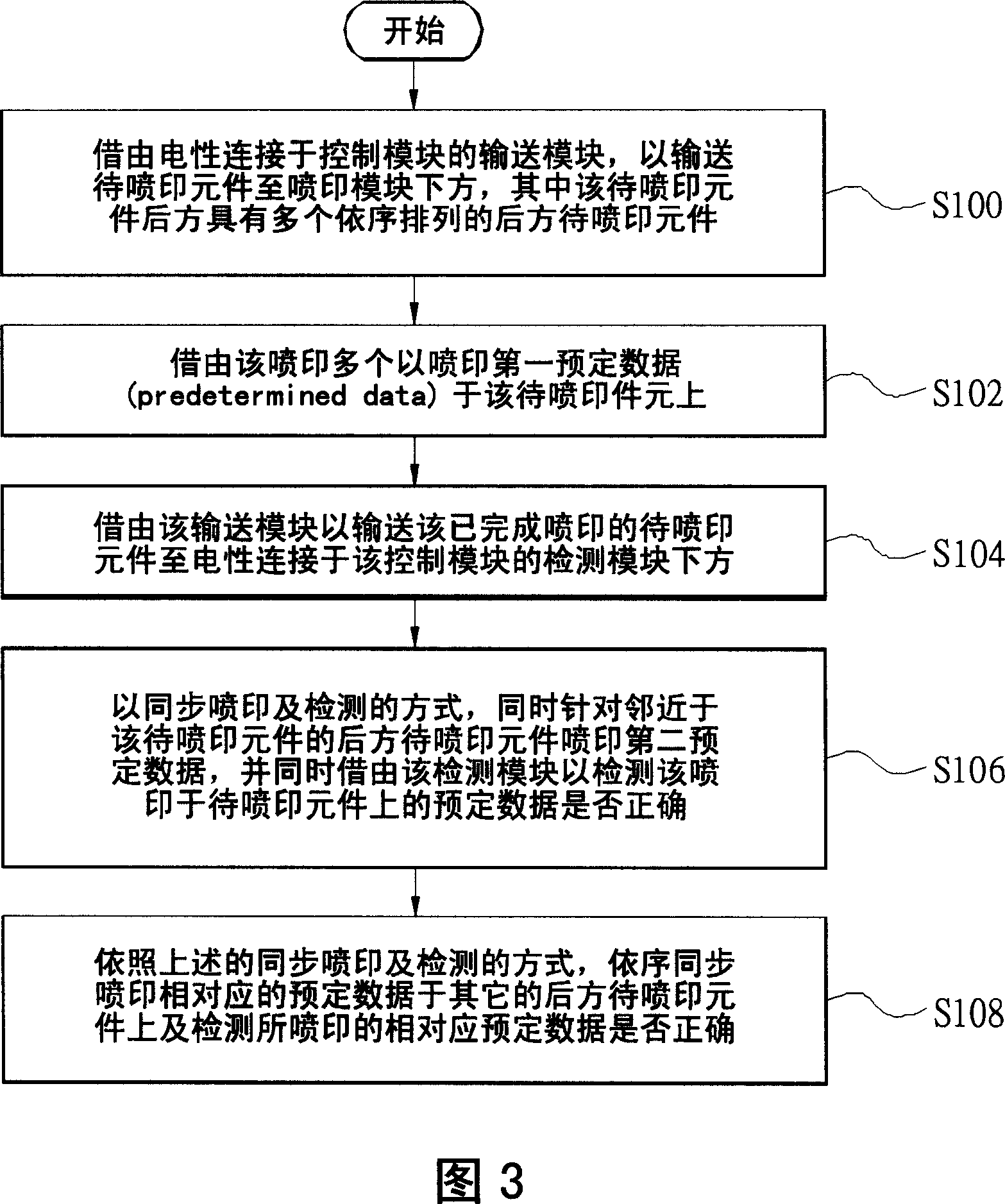

[0036] Please refer to FIG. 1 , the present invention provides an automatic printing and synchronous detection and tracking device, which includes: a conveying module 1 , a printing module 2 , a detection module 3 and a control module 4 .

[0037] The delivery module 1 can be used to deliver a plurality of components to be printed A1, A2, A3, wherein the components to be printed can be circuit boards (PCBs), multi-boards (multi-PCBs), or any components that need to be printed. Non-flat components, such as: micro-catheters, etc. In addition, the conveying module 1 can optionally convey the components to be printed in a horizontal or vertical manner, so as to perform printing in different directions.

[0038]Furthermore, the printing module 2 is disposed above the conveying module 1 , wherein the printing module 2 can be a multi-color printing module with multiple printing color options. Moreover, the printing module 2 has a main printing unit 20, which can be an ink jet printe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com