Polishing machine

A polishing machine and rotor technology, applied in the polishing machine field, can solve the problems of reducing air throughput, high pressure loss, high cost, etc., and achieve the effect of avoiding the deposition of grinding powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

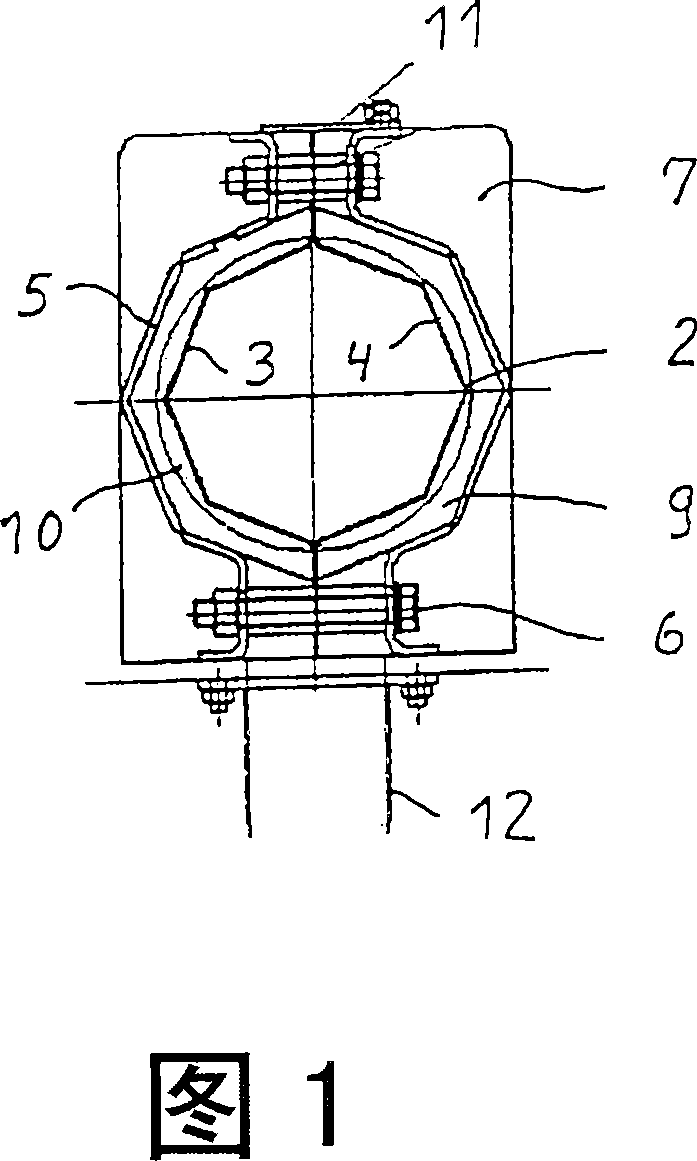

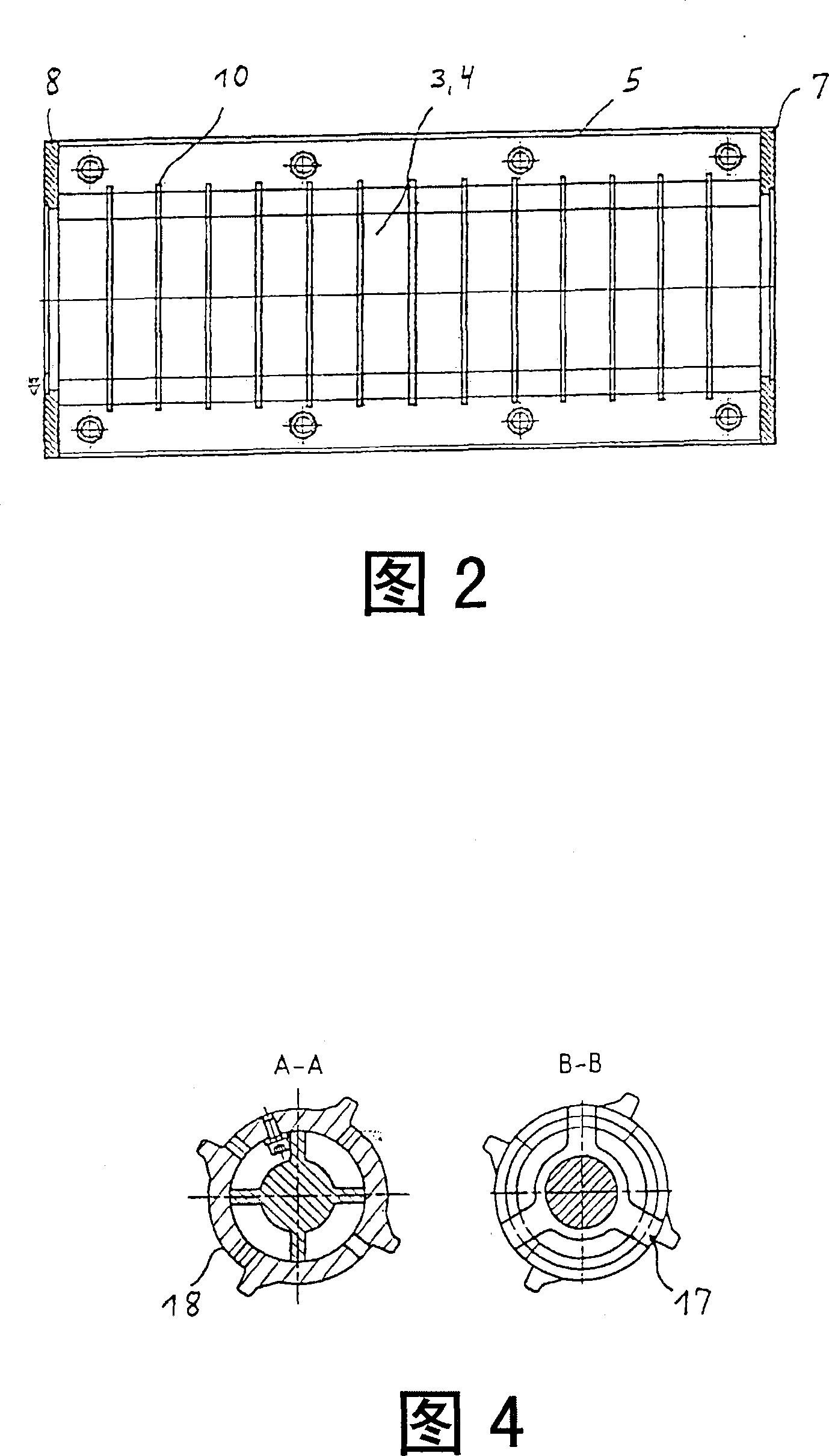

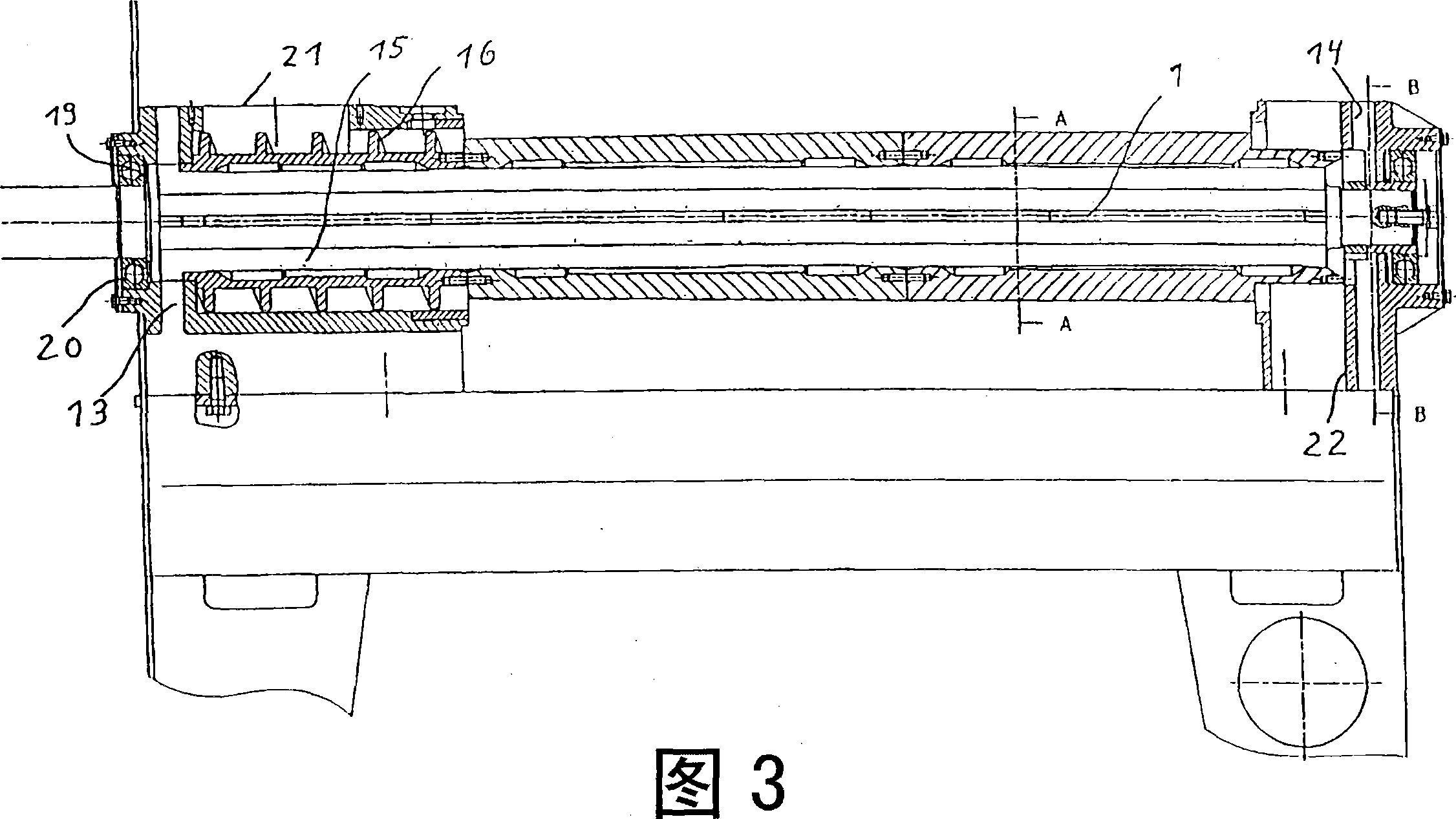

[0017] The polishing machine shown here with only the parts considered here has a cylindrical rotor 1 equipped with conventional grinding tools 18 , eg cams. In the region where the polishing tool is located, the rotor 1 is enclosed by an octagonal screen 2 comprising two screen plates 3 and 4 . The screen 2 is in turn enclosed by a two-part perforated basket 5 in the form of a sheet jacket comprising two half-shells. The screen plates 3, 4 and the perforated basket 5 are connected to the self-supporting unit by threaded connections 6 and retaining sleeves, which are sealed at the surface with the end plates 7, 8 . A uniform narrow gap 9 is located between the sieve 2 and the perforated basket, thus creating a uniform and high air velocity which allows only a slight tendency for the ground powder to settle.

[0018] The half-shells of the perforated basket 5 have short, inwardly projecting ribs 10, which are advantageously provided with plug-in protrusions. The half-shells o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com