Magnetic field method for sealing air gap

An air-gap magnetic field and air-gap technology, applied in the field of soft sealing, can solve the problems of large gap length, insufficient space, air leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

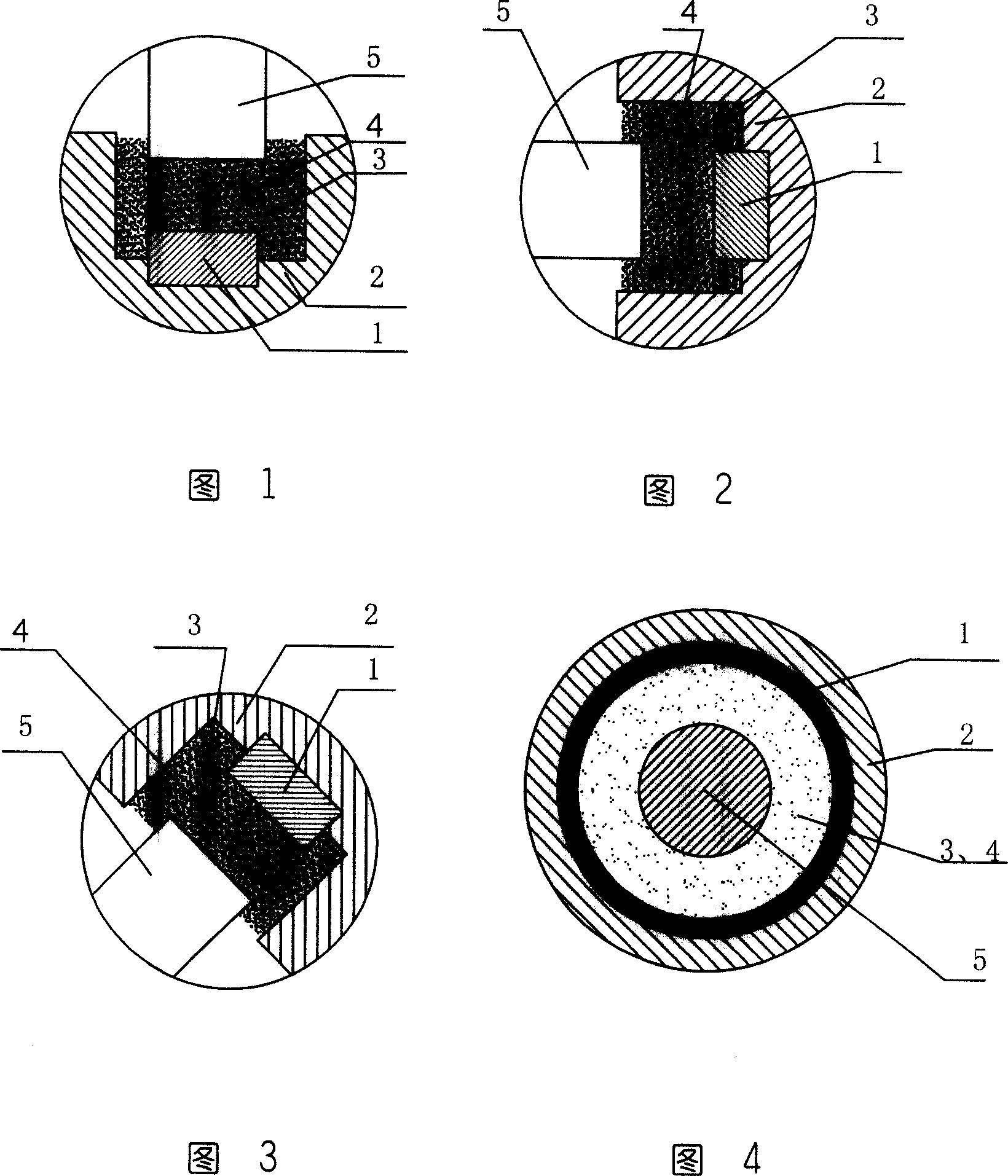

[0023] As shown in Fig. 1, the magnetic field sealing method of the present invention is adopted at the bottom of the trolley for the air gap between the sintering machine trolley and the bellows, and the magnetic field source 1 adopts the sintered NdFeB permanent magnet with the highest magnetic performance at present. A magnetic field is generated in the air gap of the sealing groove 4 formed between the fixed object 2—the bellows and the moving object 5—the sealing plate moving with the trolley, and the magnetic sealing medium 3 is filled in the magnetic field. The magnetic sealing medium is restrained by the magnetic field in the air gap of the sealing groove 4 and exists in the sealing groove to achieve the purpose of sealing.

[0024] The magnetic sealing medium used in this embodiment is composed of 80% ferrite or magnetically permeable materials NdFeB, iron, cobalt, nickel with a particle size of less than 5 μm plus 20% liquid dispersion material. The weight ratio of th...

Embodiment 2

[0027] As shown in Figure 4, the air gap at the shaft end of the gas pressurizer is sealed. The magnetic field source 1 adopts the sintered NdFeB permanent magnet with the highest magnetic performance at present, so that the fixed body 2-bearing seat and the mobile body 5-the impeller shaft form a A magnetic field is generated in the air gap of the ring groove 4; the magnetic sealing medium 3 is filled in the magnetic field. The magnetic sealing medium 3 is constrained by the magnetic field in the air gap 4 and exists in the air gap 4 to achieve the purpose of sealing.

[0028] The magnetic sealing medium 3 used in this embodiment is composed of 60% of the magnetically permeable material NdFeB powder with a particle size less than 5 μm plus 40% of the liquid dispersion material, and the weight ratio of the liquid dispersion material is polyethylene glycol 50 (polymerization degree 2000), three Ethanolamine 5, water balance. In addition to realizing the sealing function, it al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com