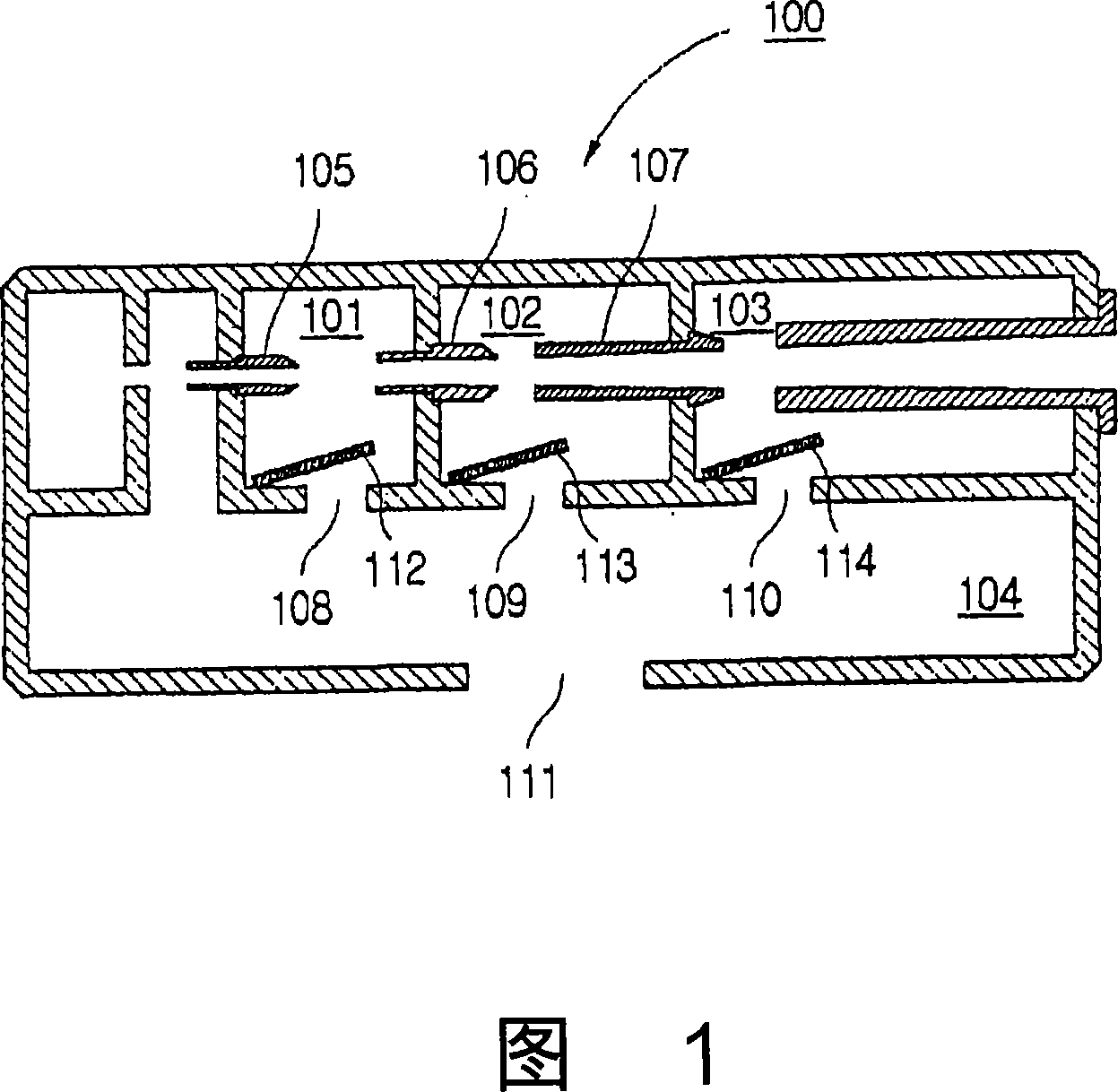

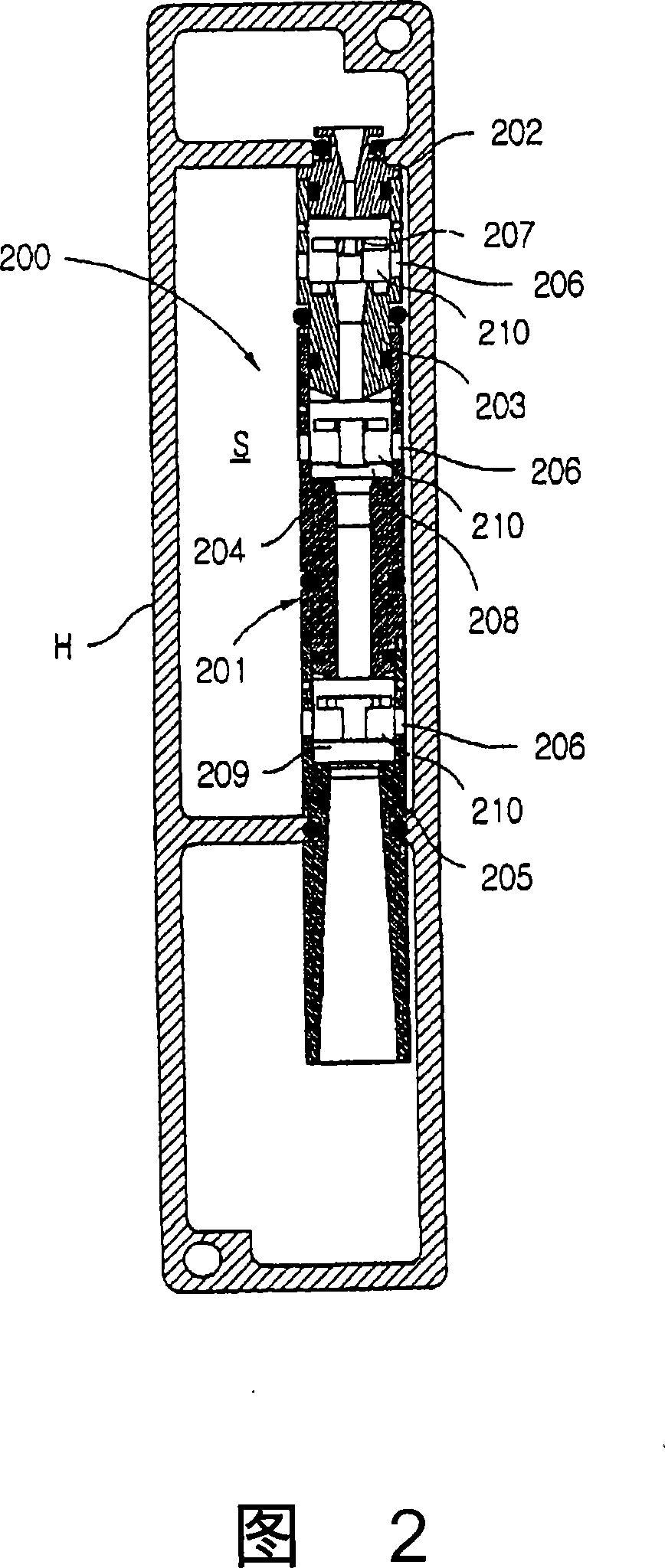

Vacuum ejector pumps

A technology for vacuum jet pumps and nozzles, which is applied to jet pumps, pumps, non-displacement pumps, etc., and can solve problems such as fracture or deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

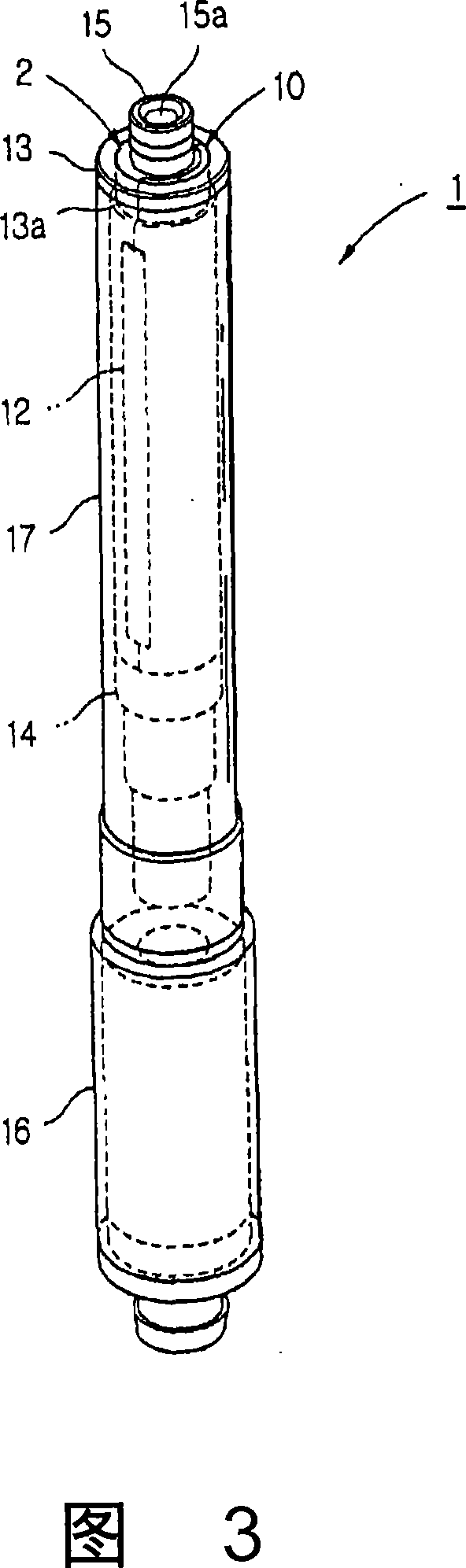

[0022] As shown in FIGS. 3 to 9, a vacuum ejector pump according to the present invention is indicated by reference numeral 1 . The jet vacuum pump 1 comprises a cylindrical nozzle body 2 , a cover 10 and fastening devices 13 and 14 . An opening 3 is provided at a predetermined position of the nozzle body 2 . A cover 10 is provided to cover the opening 3 of the nozzle body 2 . Fastening means 13 and 14 serve to fasten the nozzle body 2 to the cover 10 .

[0023] One or more mounting nozzles 4 and 5 are arranged in the nozzle body 2 and are visible through the opening 3 . The mounting nozzles 4 and 5 are arranged coaxially with the nozzle body 2 and are mounted through partition walls 6 and 7 provided in the nozzle body 2 so as to be integral with the nozzle body 2 (as shown). The mounting nozzles 4 and 5 may comprise a plurality of nozzles, so that the ejector vacuum pump 1 is characterized by the required efficiency. In this case, the installation nozzles 4 and 5 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com