Dynamic investigating method for performance of reverse osmosis antisludging agent

A technology for dynamic testing and antiscalants, applied in the direction of permeability/surface area analysis, measuring devices, instruments, etc., can solve the problem of inability to simulate continuous concentration, cannot evaluate the limit scale inhibition ability of antiscalants, and is not suitable for evaluating antiscalants, etc. problem, achieve the effect of saving manpower and material resources and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

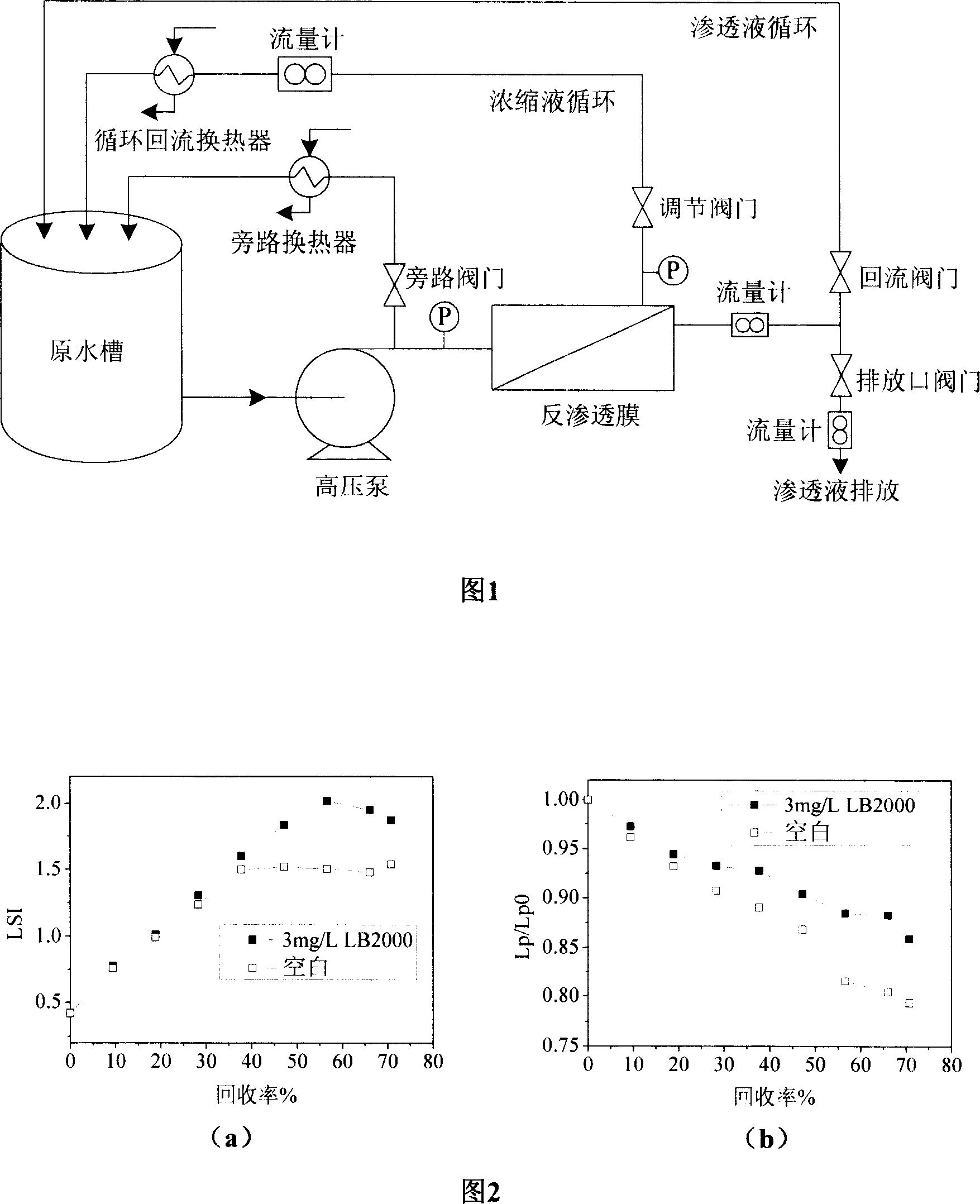

[0024] Two valves are installed at the permeate port of the reverse osmosis membrane: a return valve and a discharge valve, as shown in Figure 1, so that part of the permeate flows back to the original water tank through the return valve for circulation, and the other part is discharged through the discharge valve.

[0025] Install a regulating valve, a flow meter and a circulation reflux heat exchanger at the reverse osmosis membrane concentrate port, and make all the concentrate flow back to the raw water tank for circulation.

[0026] Install a bypass and bypass valve after the high-pressure pump to adjust flow and pressure. Recirculating heat exchanger and bypass heat exchanger are used to keep the raw water tank water temperature constant during operation

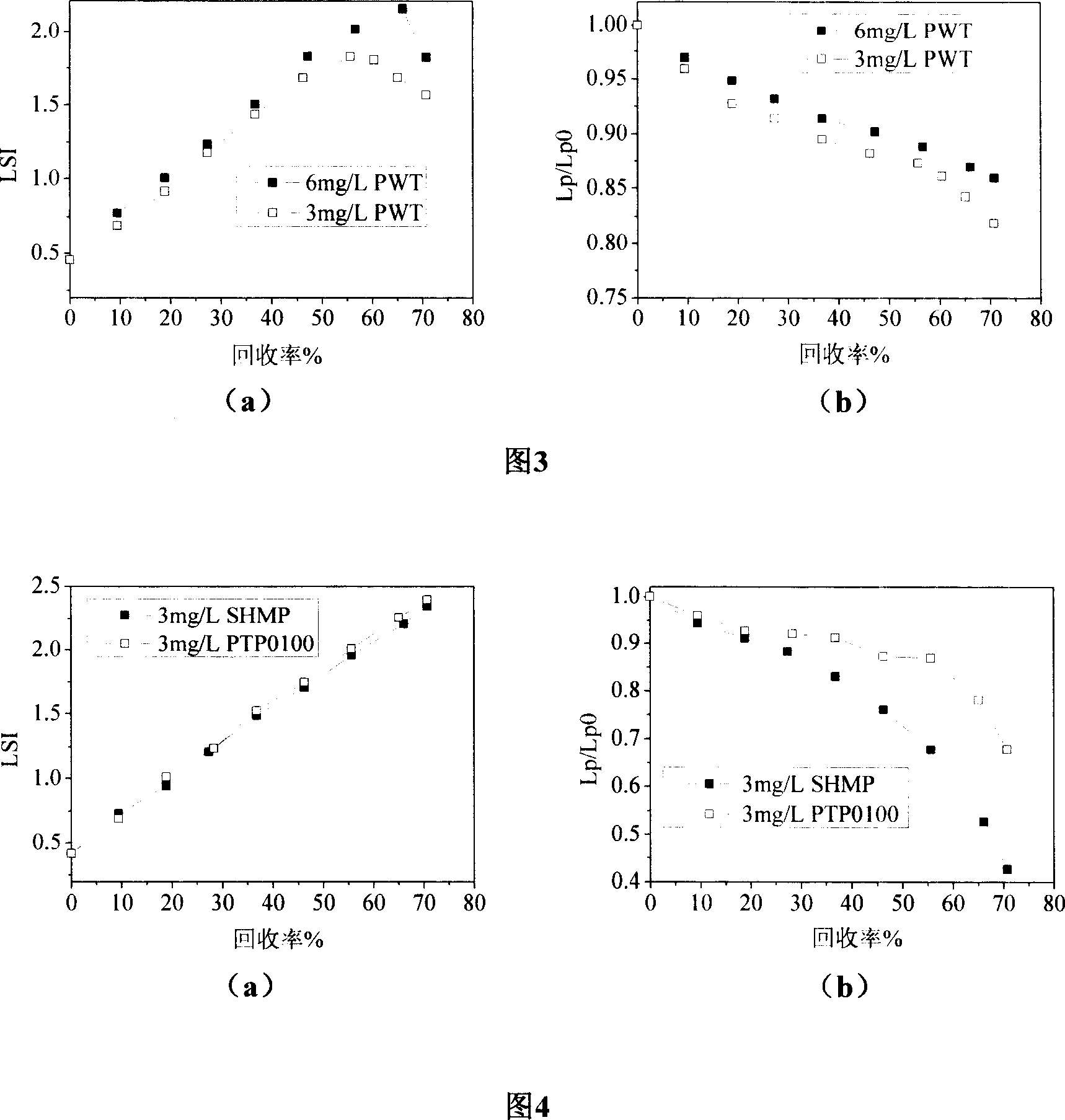

[0027] Weigh 61.47gCaCl 2 , 43.3g NaHCO 3 , 10.58 g NaNO 3 , 5.05gMgSO 4 Prepare a 106L solution in the original water tank, and adjust the pH of the solution to 7.0 with HCl. The LSI index (Langelier Saturation In...

Embodiment 2

[0034] Two valves are installed at the permeate port of the reverse osmosis membrane: a return valve and a discharge valve, as shown in Figure 1, so that part of the permeate flows back to the original water tank through the return valve for circulation, and the other part is discharged through the discharge valve.

[0035] Install a regulating valve, a flow meter and a circulation reflux heat exchanger at the reverse osmosis membrane concentrate port, and make all the concentrate flow back to the raw water tank for circulation.

[0036] Install a bypass and bypass valve after the high-pressure pump to adjust flow and pressure. Recirculating heat exchanger and bypass heat exchanger are used to keep the raw water tank water temperature constant during operation

[0037] Weigh 61.47gCaCl 2 , 43.3g NaHCO 3 , 10.58 g NaNO 3 , 5.05gMgSO 4 Prepare a 106L solution in the original water tank, and adjust the pH of the solution to 7.0 with HCl. The LSI index of the solution is 0.42,...

Embodiment 3

[0044] Two valves are installed at the permeate port of the reverse osmosis membrane: a return valve and a discharge valve, as shown in Figure 1, so that part of the permeate flows back to the original water tank through the return valve for circulation, and the other part is discharged through the discharge valve.

[0045] Install a regulating valve, a flow meter and a circulation reflux heat exchanger at the reverse osmosis membrane concentrate port, and make all the concentrate flow back to the raw water tank for circulation.

[0046] Install a bypass and bypass valve after the high-pressure pump to adjust flow and pressure. Recirculating heat exchanger and bypass heat exchanger are used to keep the raw water tank water temperature constant during operation

[0047] Weigh 61.47gCaCl 2 , 43.3g NaHCO 3 , 10.58 g NaNO 3 , 5.05gMgSO 4 Prepare a 106L solution in the original water tank, and adjust the pH of the solution to 7.0 with HCl. The LSI index of the solution is 0.42,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com