Drying cabinet of ultraviolet printer

A technology of ultraviolet rays and printing machines, applied in printing machines, general parts of printing machinery, printing, etc., can solve problems such as excess antioxidants, environmental pollution, and increased production costs of printed matter, so as to achieve strong market competitiveness and reduce production costs , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

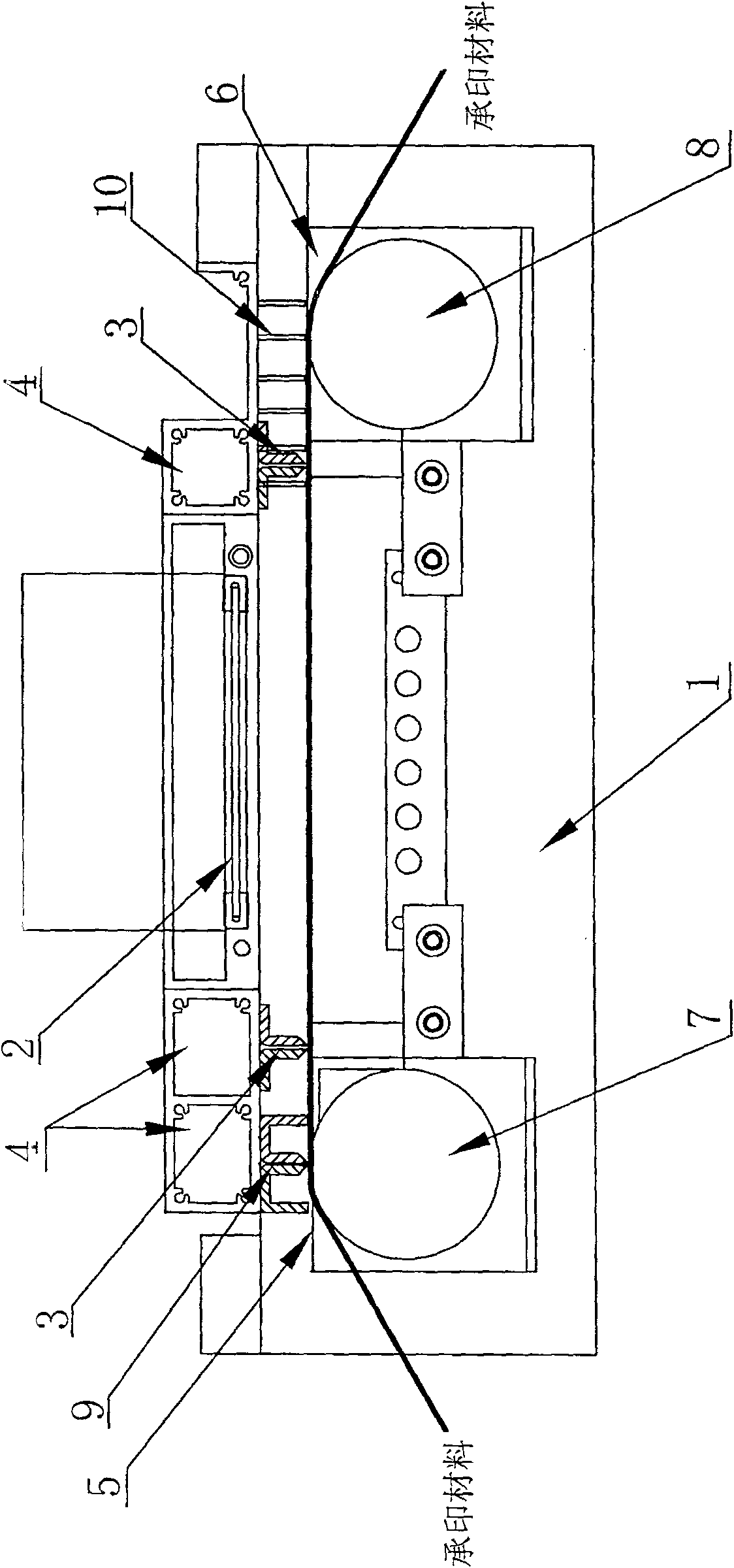

[0011] refer to figure 1 , a drying box for an ultraviolet printing machine, comprising a light box 1 and an ultraviolet lamp tube 2 installed in the light box 1, a compensation gas valve 3 is arranged in the light box 1, and the compensation gas valve 3 is provided with a protective gas source interface 4 , the two ends of the light box 1 are respectively provided with an entrance 5 and an exit 6, and the inner side of the light box 1 is respectively provided with a front paper guide roller 7 and a rear paper guide roller 8 at the entrance 5 and the exit 6, and the light box 1 is provided with two compensating Air valve 3, the two compensating air valves 3 are arranged respectively near the front paper guide roller 7 and the rear paper guide roller 8, and the inlet 5 is provided with an air knife 9 with an air outlet facing the front paper guide roller 7, the The outlet 6 is provided with a gas stop device to prevent outside gas from entering; the air knife 9 and the gas stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com