Apparatus for sorting according to colour

A sorting device and color technology, used in sorting, solid separation, sieving, etc., can solve problems such as unsatisfactory, small bounce coefficient, and difficulty, and improve sorting efficiency or processing capacity. Productivity and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

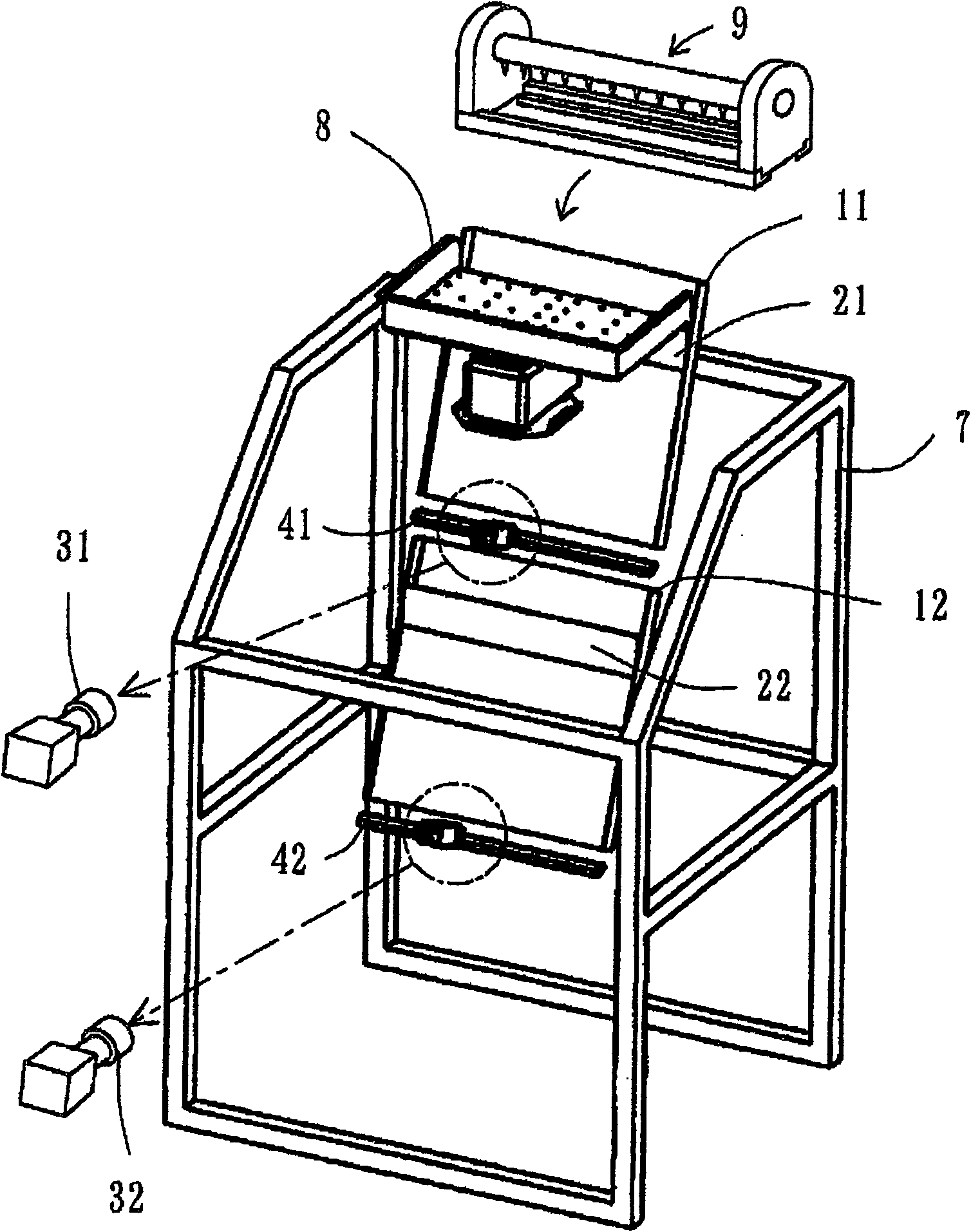

[0051] now refer to image 3 and 4 Another embodiment of the sorting device by color according to the present invention will be introduced.

[0052] image 3 is a schematic perspective view of the color sorting device of this other embodiment, Figure 4 is along image 3 A cutaway view of the center of the color-sorting device shown.

[0053] Such as image 3 and 4 As shown, the sorting device by color in this other embodiment includes a pair of slides 11 and 12 arranged at a certain angle to the horizontal to allow the object W to be sorted to move downward, and arranged to be connected to the slides 11 and 12 respectively. There is a pair of covers 21 and 22 at a distance for covering at least a part of their respective slides 11 and 12, a pair of inspection devices 31 and 32 for inspecting the color of the object W, connected to the inspection device for analysis An identification device 5 for identifying a defective product from the object W by checking the output s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com