Ultrasonic wave welding head of ultrasonic wave hair adhesive device

An ultrasonic and hair technology, used in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve problems such as cracks, poor durability, and brittleness, and achieve the effect of improving durability and stabilizing ultrasonic vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

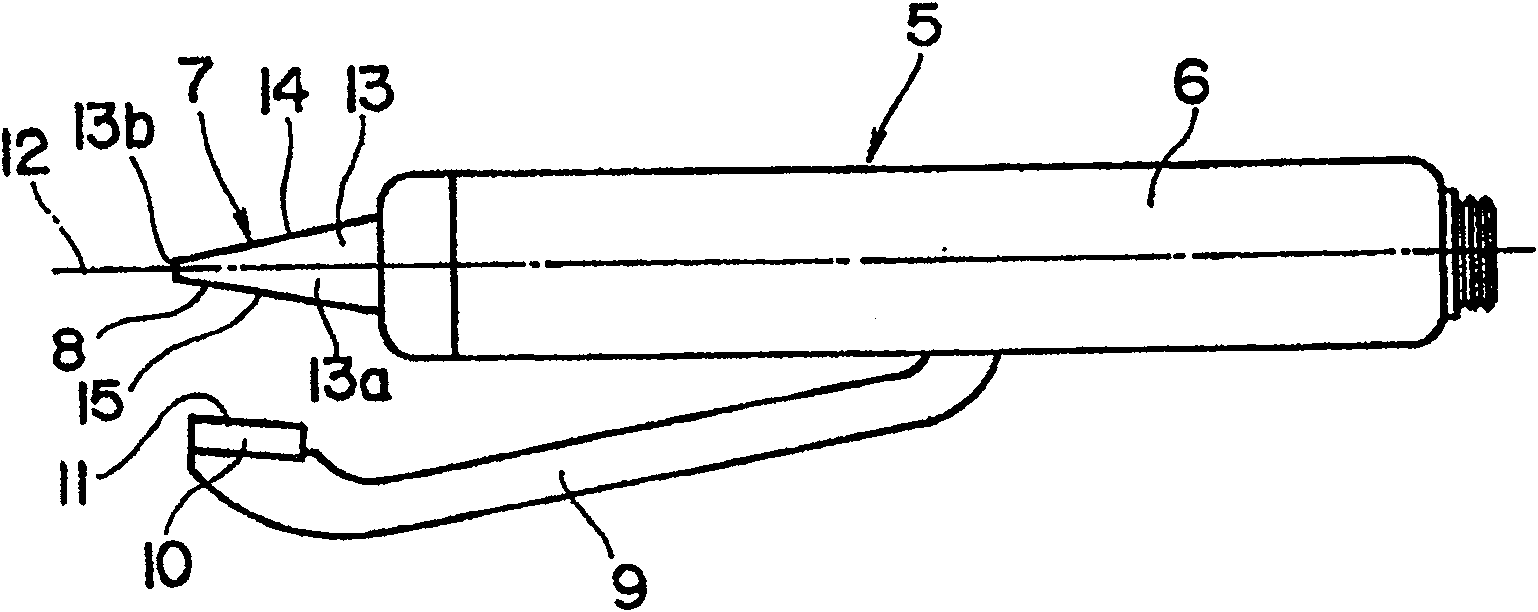

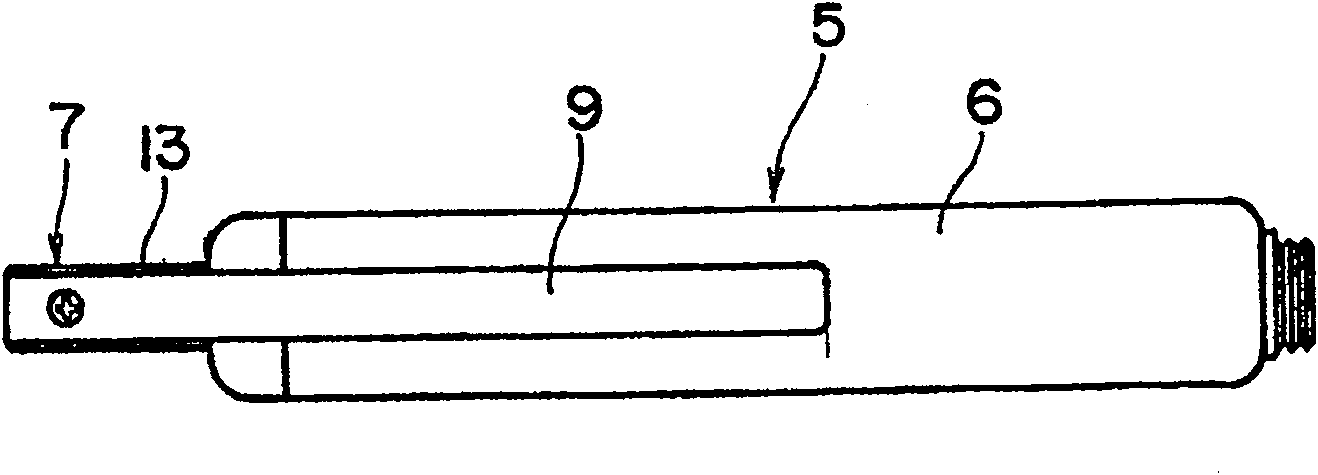

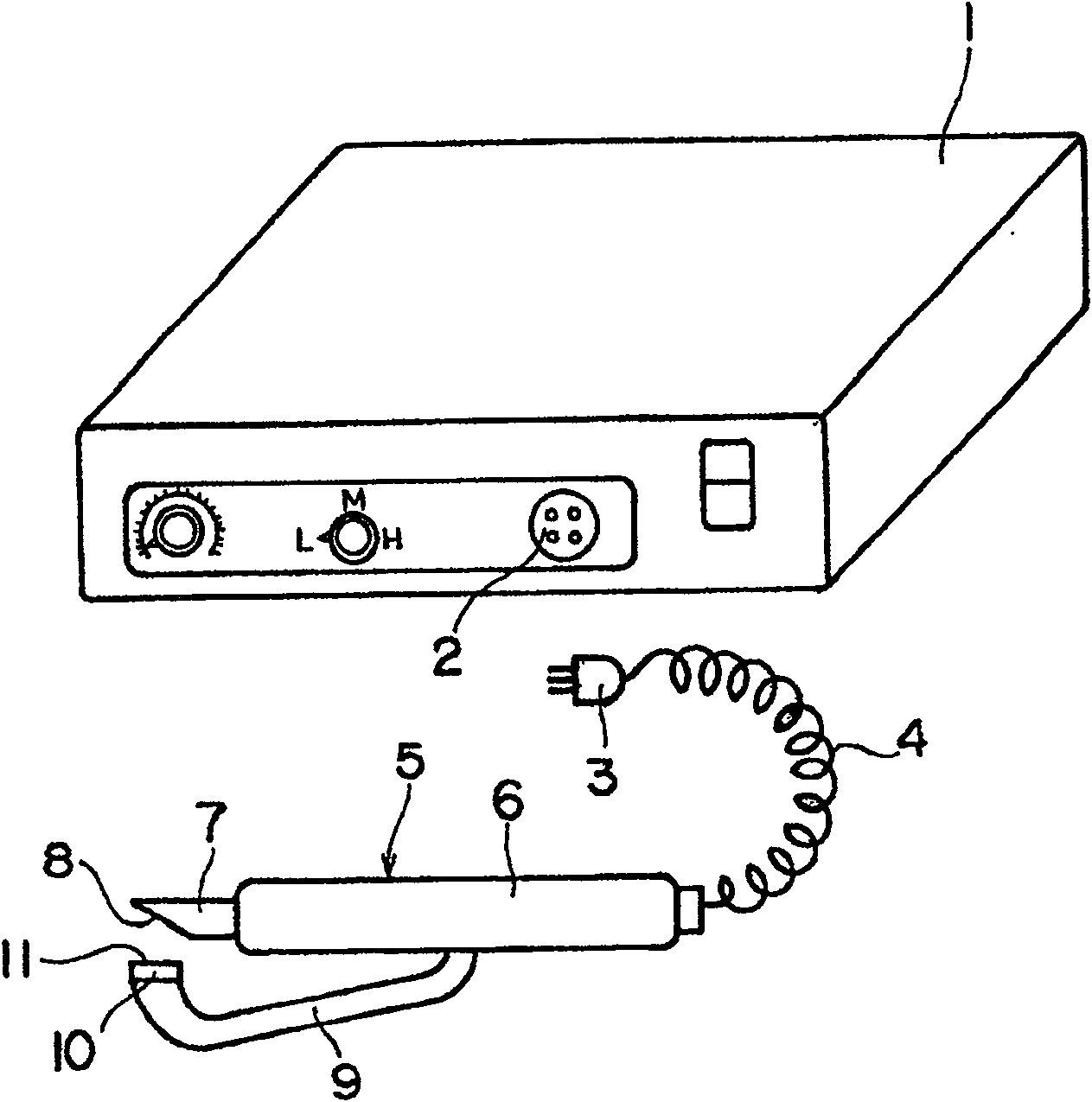

[0013] figure 1 and figure 2 Representing the preferred embodiment of the ultrasonic horn for implementing the ultrasonic hair bonding device of the present invention, figure 1 is the main view, figure 2 is its bottom view. Additionally, for the aforementioned image 3 and Figure 4 Corresponding parts are given the same symbol to indicate.

[0014] As shown in the figure, protruding from the front end of the housing 6 of the handpiece 5 with the built-in ultrasonic generator (not shown) is an ultrasonic horn 7 connected to the front end of the ultrasonic generator. In this ultrasonic horn 7, tapered surfaces 14, 15 are symmetrically formed across the central axis 12 of the ultrasonic horn body 13 on the front end portion 13a of the aluminum ultrasonic horn main body 13, and the tapered surfaces 14, 15 One of the faces is used as the working face 8.

[0015] A rod 9 is rotatably mounted on the casing 6 of the handpiece 5 , and a pressing portion 10 is provided at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com