Self-discharging goods case of side-turn bottom board

A rollover type, bottom plate technology, which is applied in the direction of tilting bearing motion vehicles, etc., can solve the problems of time-consuming, poor safety, and complex structure of hammer-type door locks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

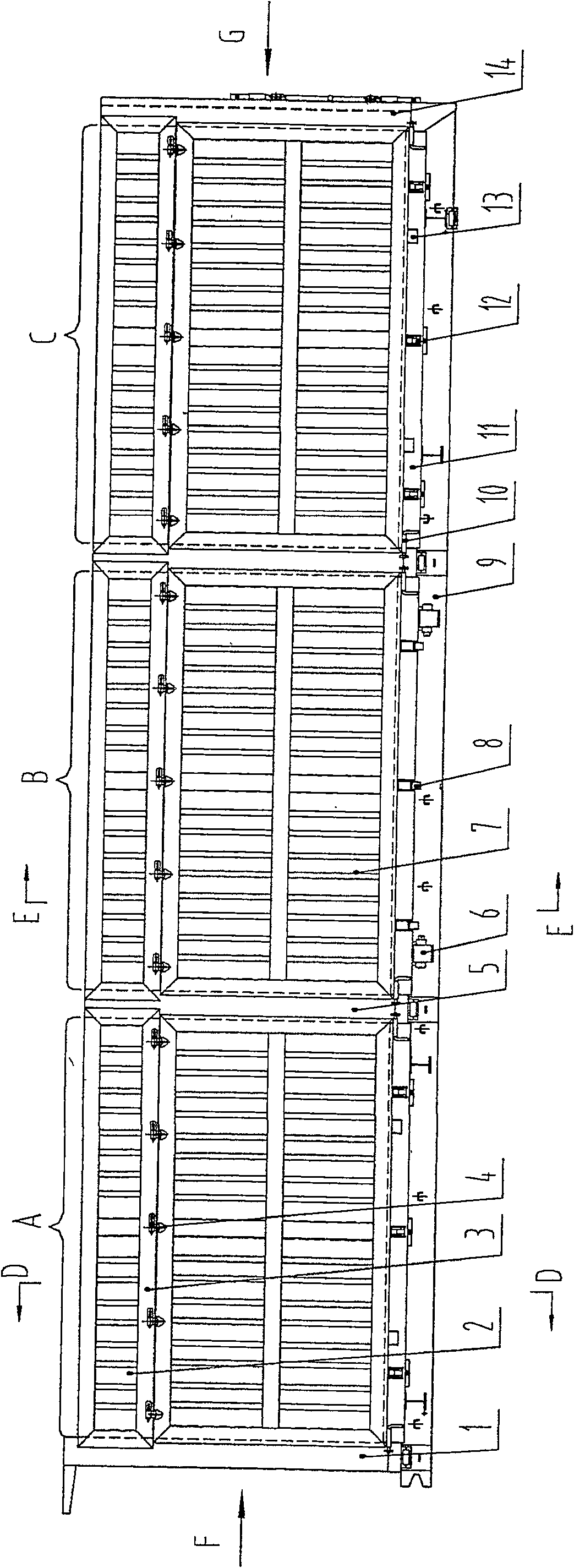

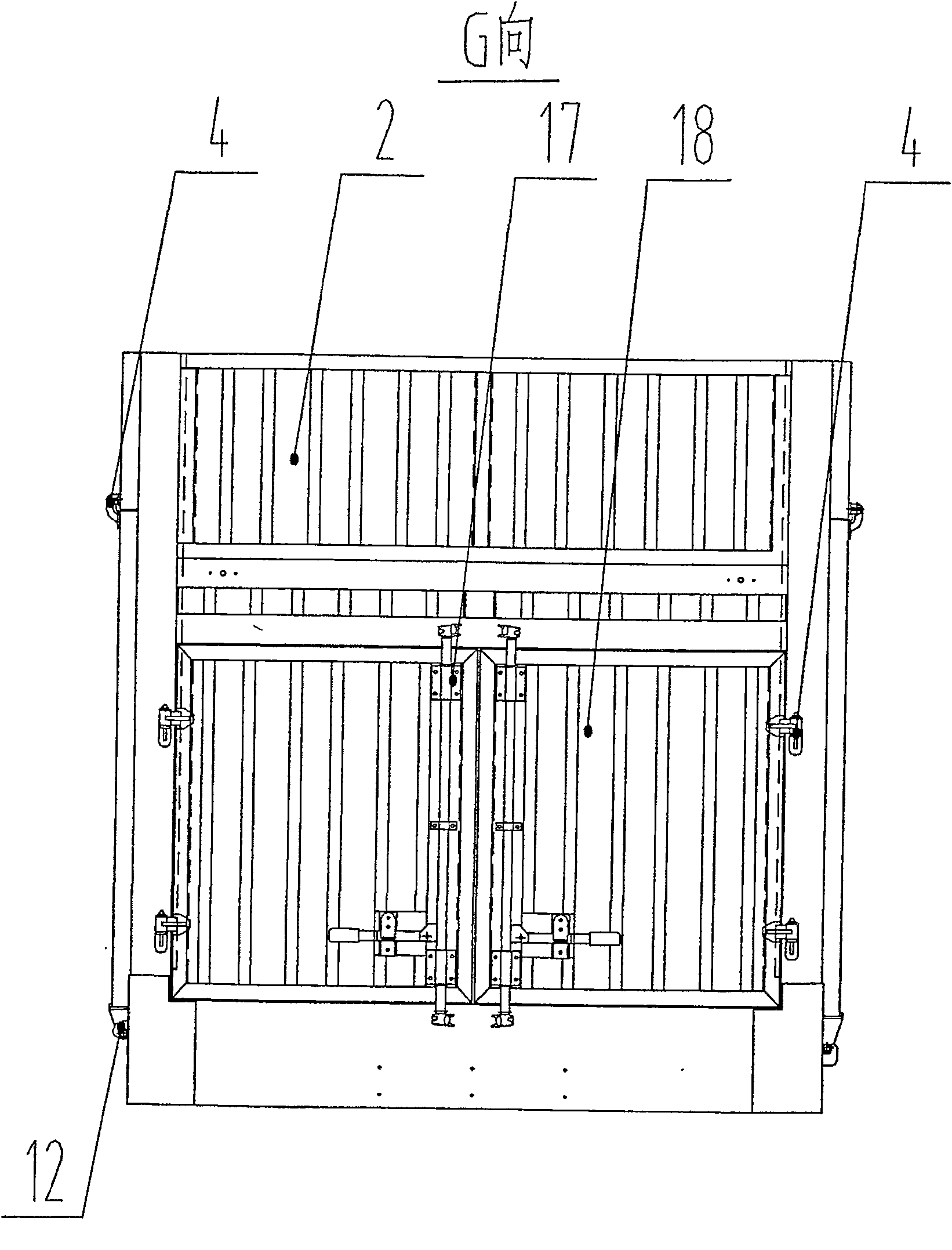

[0018] The present invention will be further described below in conjunction with accompanying drawing. refer to figure 1 , the present invention is composed of the front box body A, the middle box body B, and the rear box body C into an integral self-unloading container. Constitute the upper frame of the box body, the lower end of the fixed box plate frame 3 is hoisted by the rotating hinge shaft 4 to lift the movable box plate 7, the side of the bottom frame 9 is equipped with a turning bushing 6, and the bottom frame 9 is equipped with a lifting bottom plate 11, and the lifting bottom plate 11 Overturn lock hook 8 is equipped with on the lower side. refer to figure 2 , the figure is the front view of the front box panel 1, showing the state that the fixed box panel 2 and the movable box panel 7 on the side of the box are connected through the rotating hinge shaft 4, and the top of the front box panel 1 has a water inlet 15, and the bottom end With water discharge pipe mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com