Building foundation pit supporting construction

A foundation pit support and building technology, applied in the field of foundation engineering, can solve the problems of foundation pit safety cannot be guaranteed, long construction period and high project cost, so as to save foundation construction period, reduce construction cost, and improve comprehensive project benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

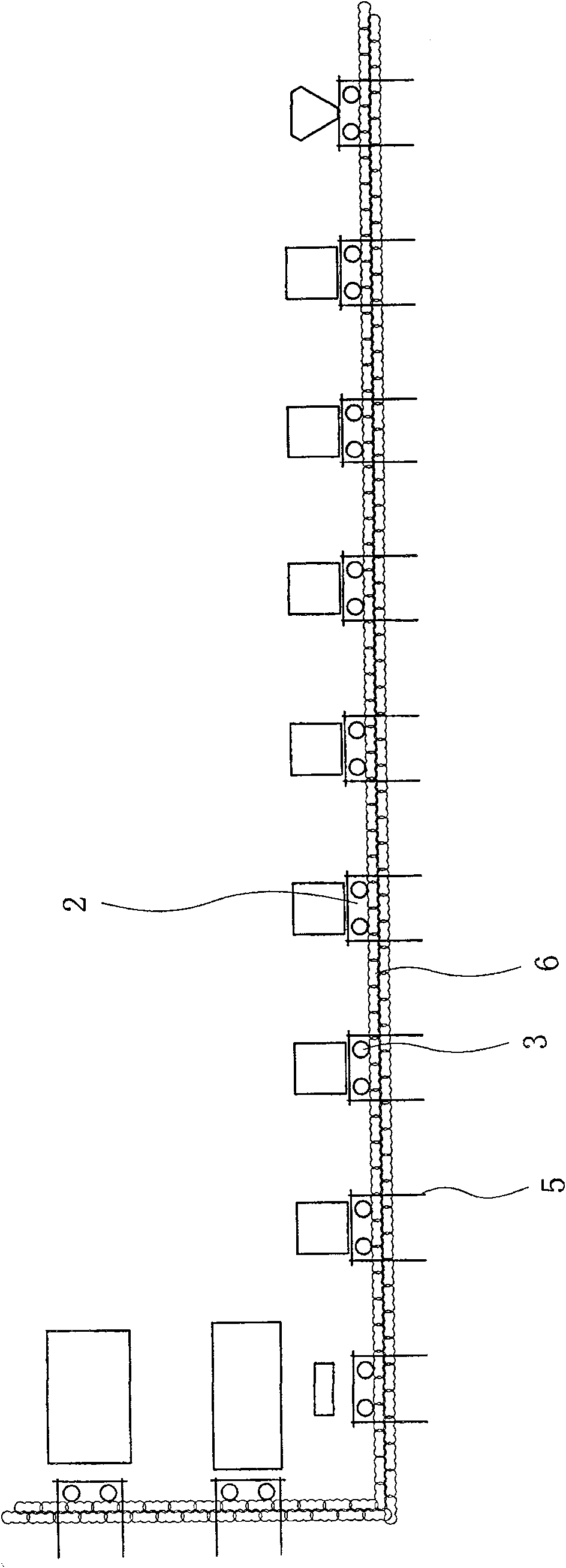

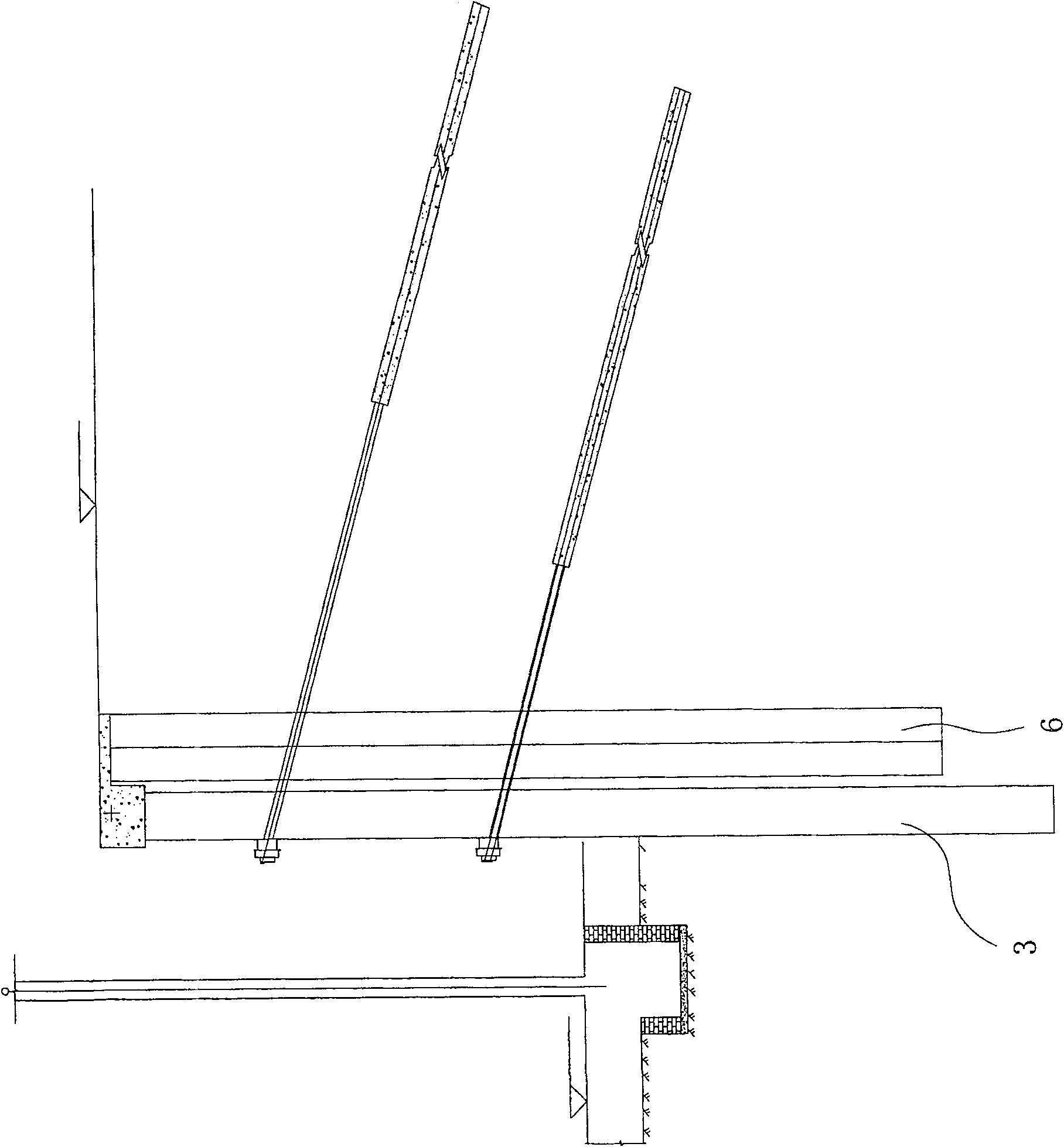

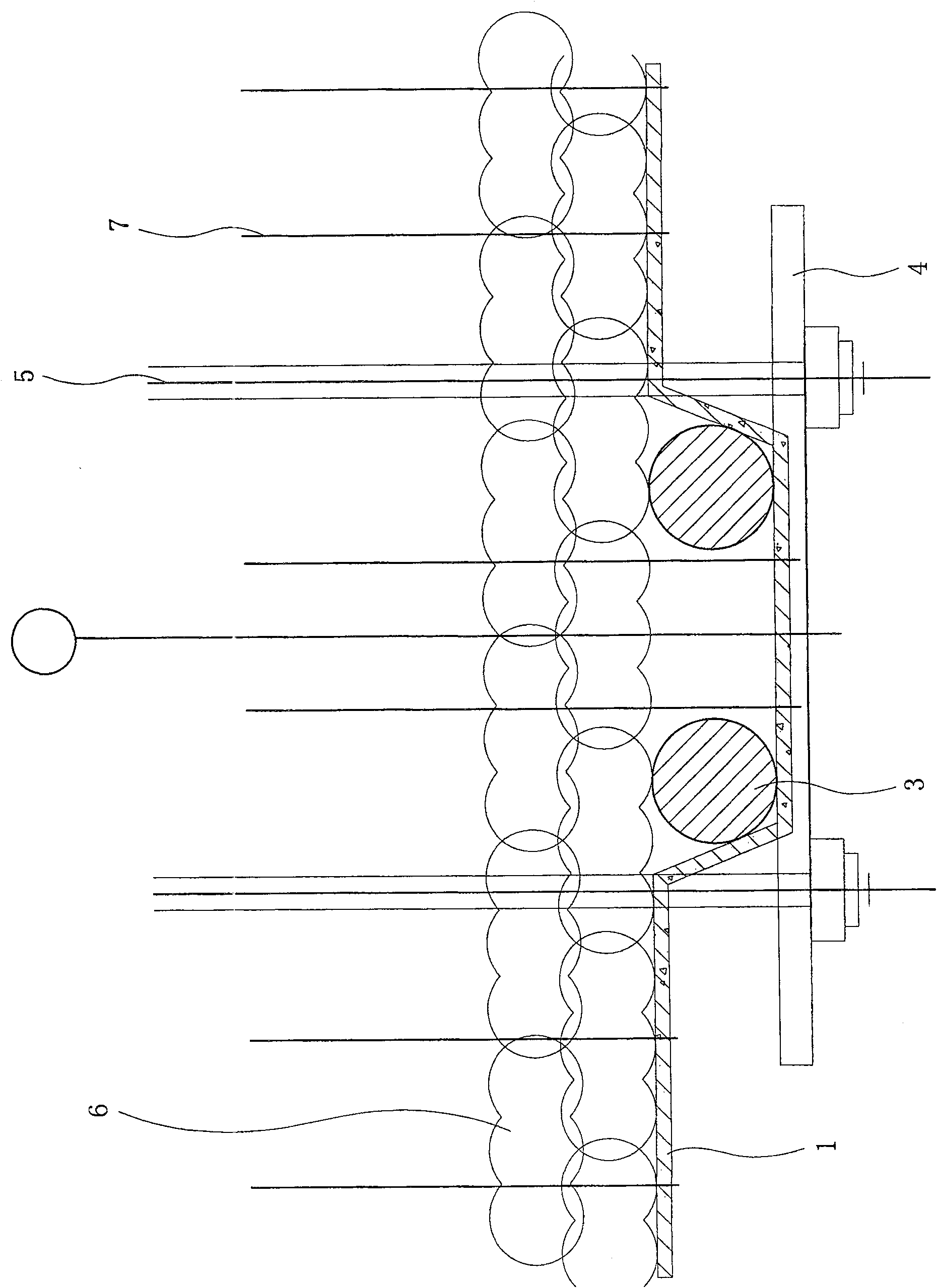

[0026] Embodiment one: see Figure 1 to Figure 4 As shown, a building foundation pit support structure, including a soil nail wall 1 around the foundation pit and a prestressed anchor rod 5 inserted in the soil body through the soil nail wall, along the soil nail wall every 5 to 10 meters A pier column structure 2 (open pier structure) protruding from the peripheral surface of the foundation pit is provided. The pier column structure includes cast-in-situ pile groups perpendicular to the bottom surface of the foundation pit, and the prestressed anchors on both sides of the cast-in-place pile group are respectively rod, and the horizontal channel steel 4 connecting the anchor rods on both sides to be located at the outer end of the soil nail wall. The cast-in-situ pile group is wrapped in the soil nail wall and consists of two cast-in-situ piles 3 arranged in parallel. The periphery of the foundation pit, The inner side of the soil nail wall and the cast-in-place pile is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com