Step-by-step type energy absorption device during collision of automobiles

An energy absorbing device and collision energy absorbing technology, applied in vehicle parts, transportation and packaging, substructure and other directions, can solve the problem of unfavorable energy absorbing occupant protection, can not achieve the effect of collision energy absorbing occupant protection, and the rear part of the collision acceleration peak is large. Body structure and other issues, to achieve the effect of simple and compact structure, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

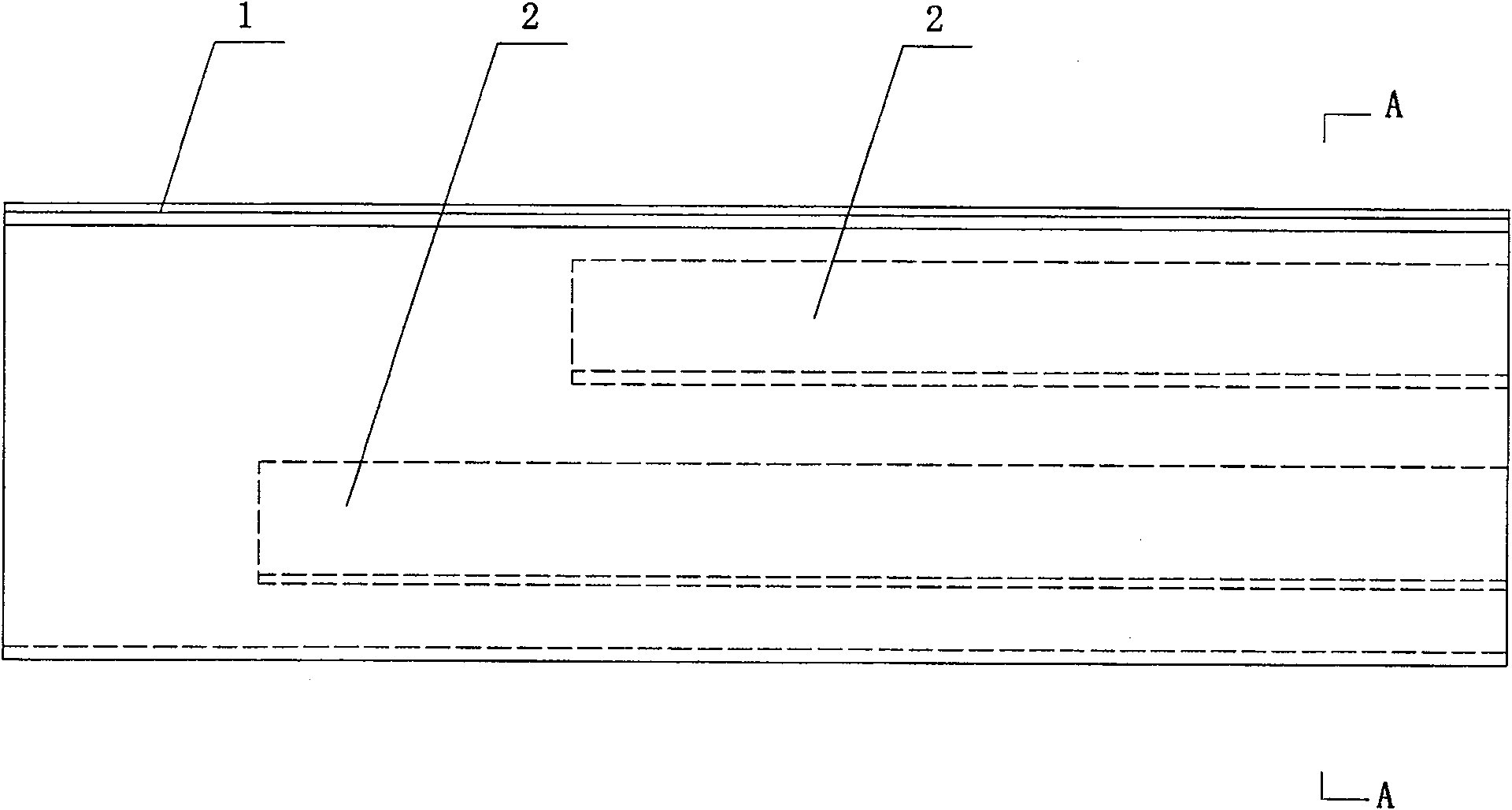

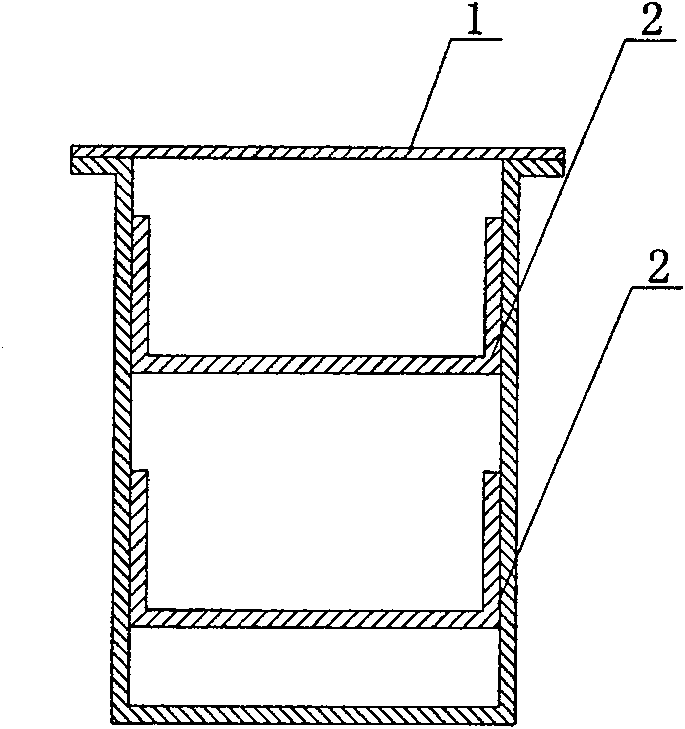

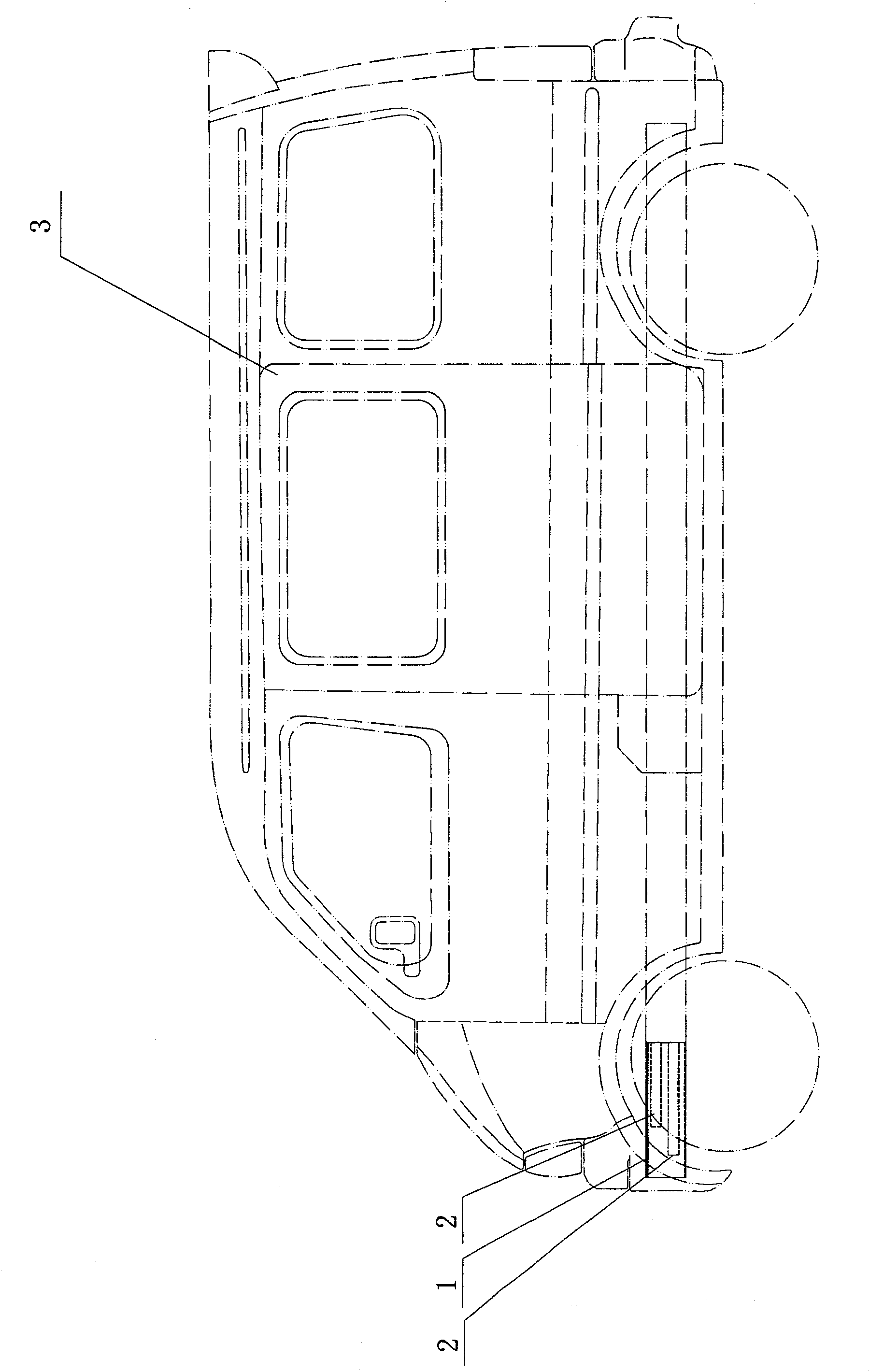

[0015] Such as figure 1 , figure 2 and image 3 As shown, the automobile collision energy-absorbing device step by step of the present invention includes an energy-absorbing beam 1, and one or more reinforcing plates 2 are installed inside the energy-absorbing beam 1. In this embodiment, the energy-absorbing beam 1 is a square beam with a hollow inside. The energy-absorbing beam 1 is provided with two reinforcing plates 2 , both of which are in the shape of channel steel, and the arrangement direction of the reinforcing plates 2 is the same as that of the energy-absorbing beam 1 . The reinforcing plate 2 is welded and fixed in the energy-absorbing beam 1. The length and thickness of the two reinforcing plates 2 can be selected and combined according to actual needs. When it is necessary to increase or reduce the energy-absorbing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com