X-ray measuring instrument

A measuring device, X-ray technology, applied in the direction of radiological diagnostic instruments, medical science, diagnosis, etc., can solve the problem that the three-dimensional image cannot express the correct value, and achieve the effect of eliminating the saturation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Hereinafter, a first embodiment of the present invention will be described.

[0025] The control processing unit 406 of the present invention executes a process of correcting the non-uniformity of the value of the three-dimensional image. The control processing unit 406 has a storage unit 409 inside, and stores tables and the like necessary for correction processing. As an input mechanism of the control processing device 406, although not shown, key input from a keyboard, reading from a file, and replacement of a memory chip are conceivable. The control processing device 406 has a mode, a switch, and the like for inputting whether or not to execute the correction process as an operation menu.

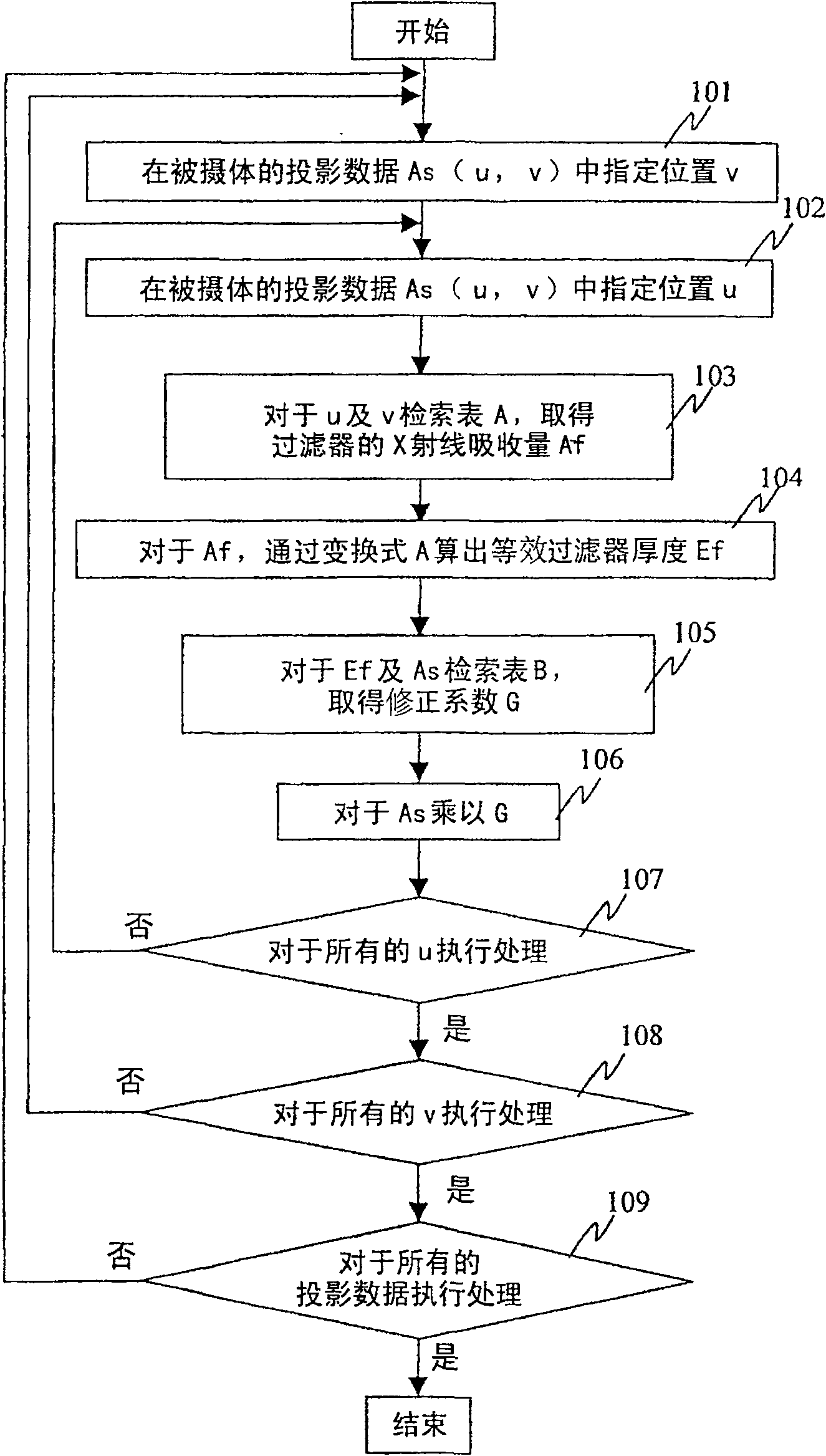

[0026] The procedure for correcting the value non-uniformity of the three-dimensional image will be described below.

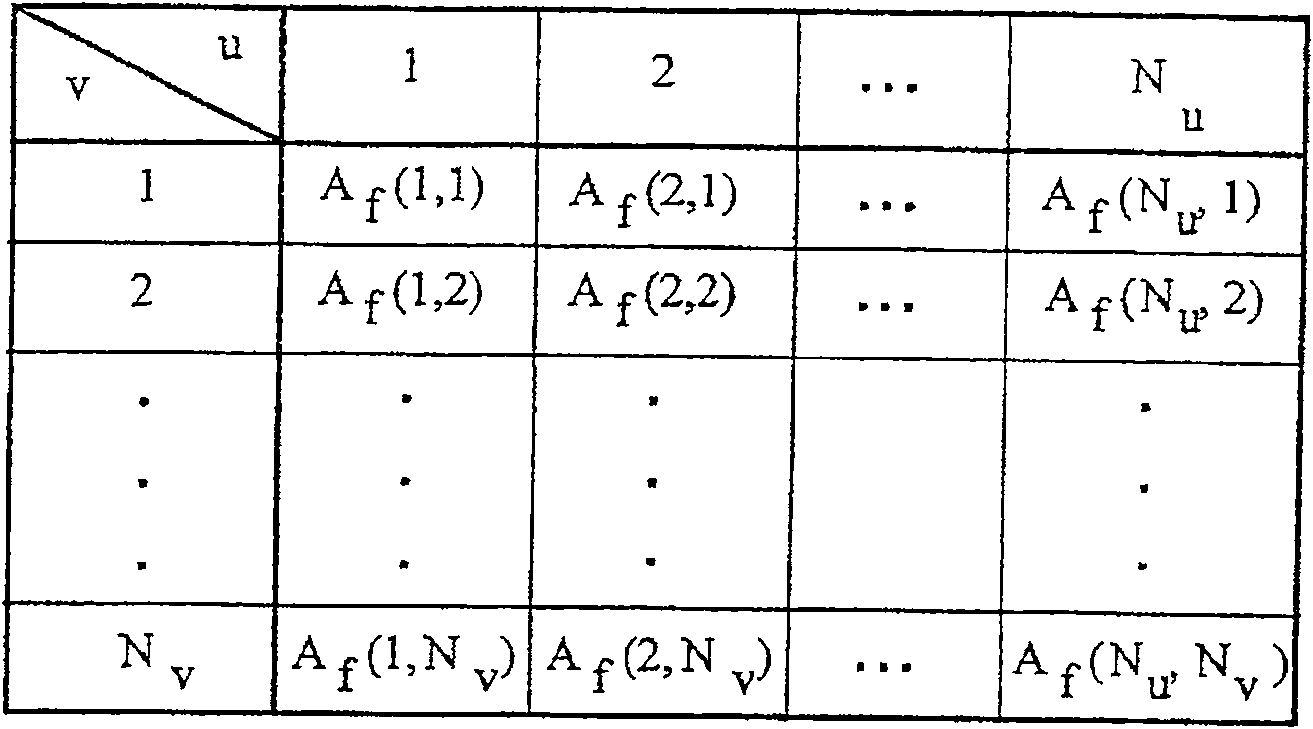

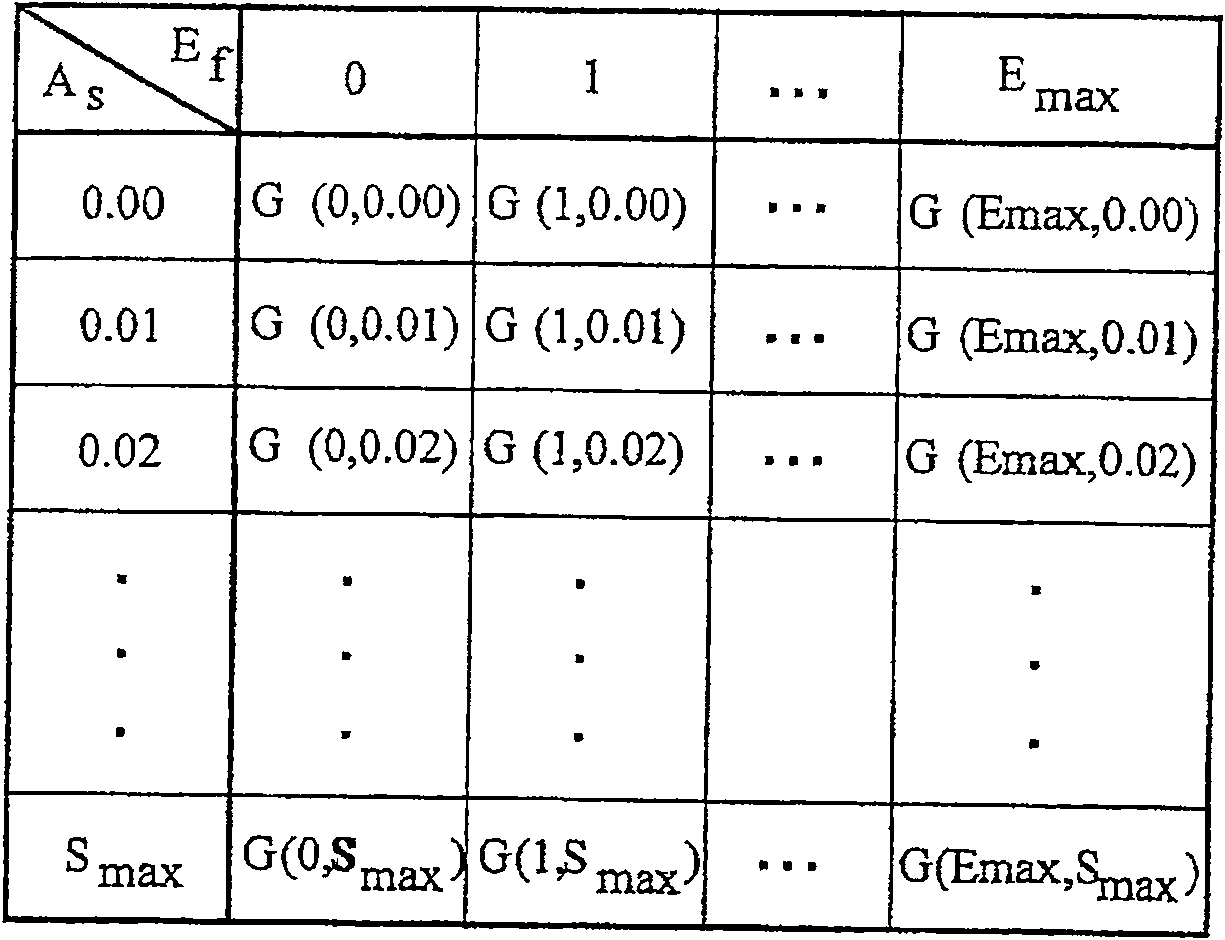

[0027] (1) Acquisition of sensitivity data: measurement is performed by irradiating X-rays in a state where no subject is set, and sensitivity data of the dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com