Non-kinetic inherently safe tube-pool type reactor

An inherently safe, reactor technology, applied in the field of nuclear reactors, can solve problems such as core water loss acceleration, core water loss, and inability to escape, and achieve the effect of a reliable passive safety system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

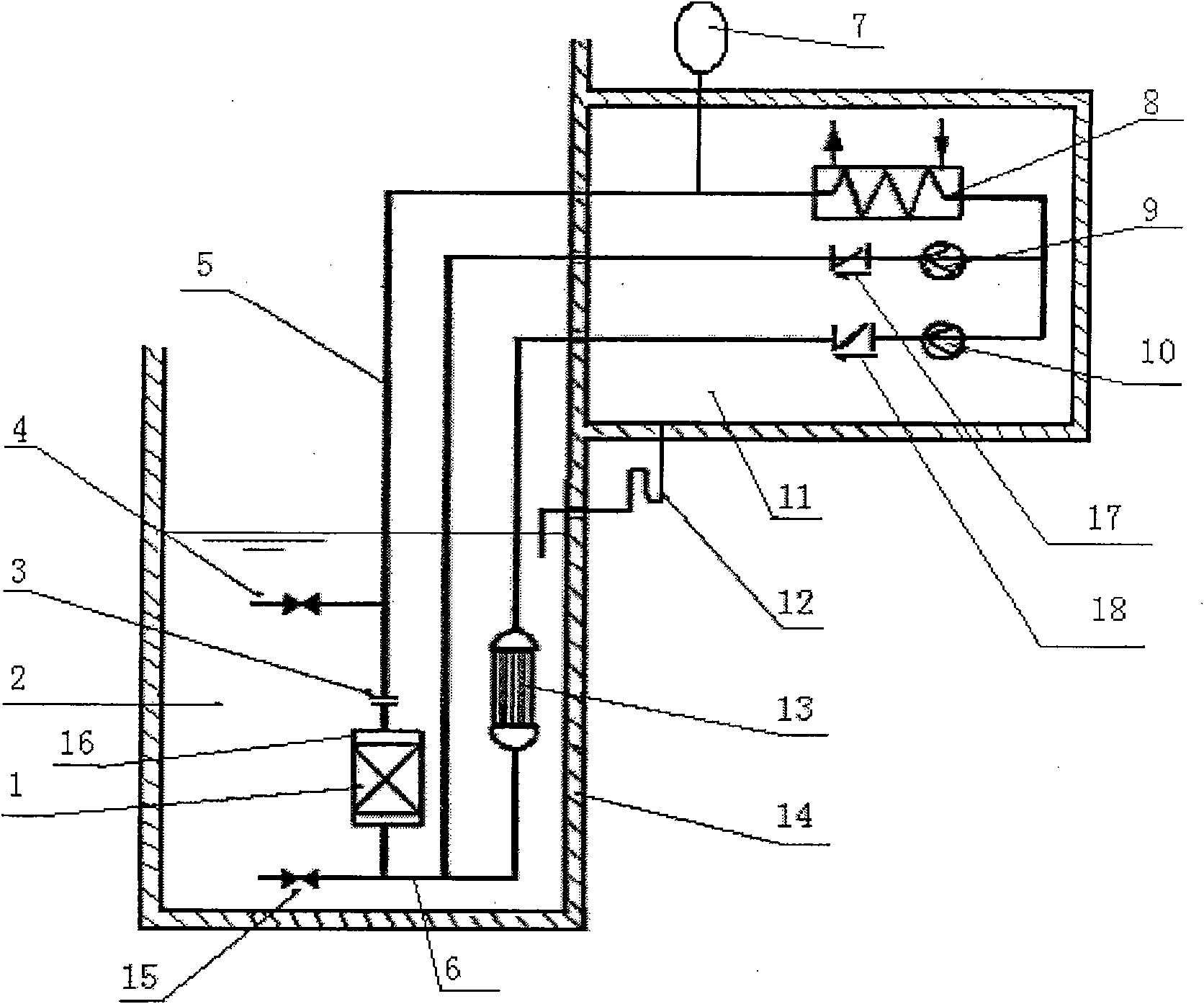

[0022] Such as figure 1 In the tube pool reactor shown, the reactor pressure vessel 16 is installed in the reactor pool 2, the reactor core 1 is installed in the reactor pressure vessel 16, and the upper part of the reactor pressure vessel 16 communicates with the main heat exchanger 8 through the reactor cooling water outlet pipe 5; The main heat exchanger 8 communicates with the reactor cooling water inlet pipe 6 through two parallel pipelines, one of which is connected with the reactor cooling water main pump 9 and the main pump outlet check valve 17 in sequence, and the other pipeline is connected with the waste heat The export pump 10, the waste heat export pump outlet check valve 18, the waste heat exchanger 13, and the waste heat exchanger 13 is located in the pool 2; the reactor cooling water inlet pipe 6 communicates with the lower part of the reactor pressure vessel 16; the reactor cooling water outlet pipe 5 is next to A voltage stabilizer 7 is connected on the road...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com