Press machine

A mechanical and pressure technology, applied in the direction of presses, stamping machines, forging presses, etc., can solve the problems such as the inability to adjust the height of the slider, achieve the effect of good sliding action, improved versatility, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

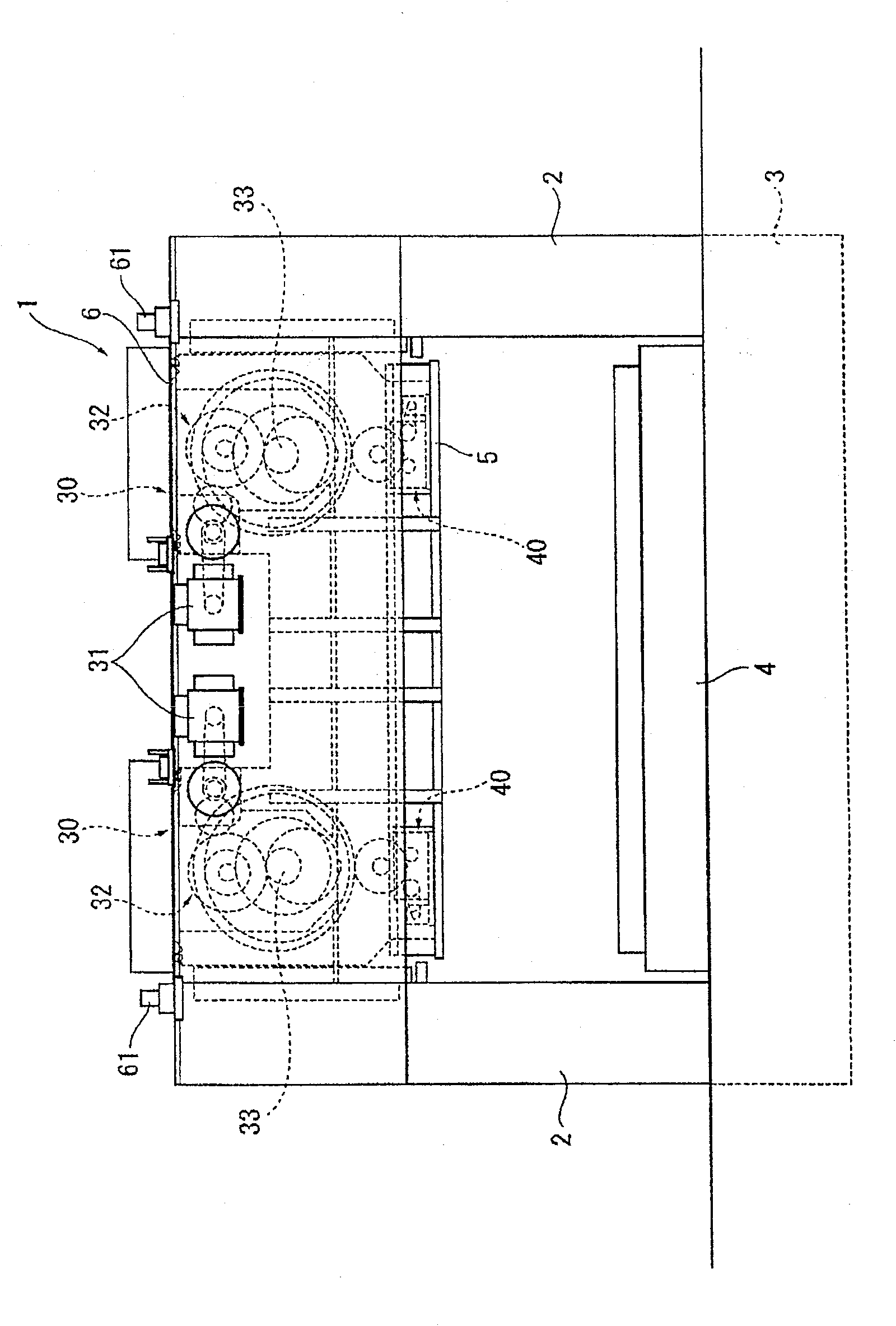

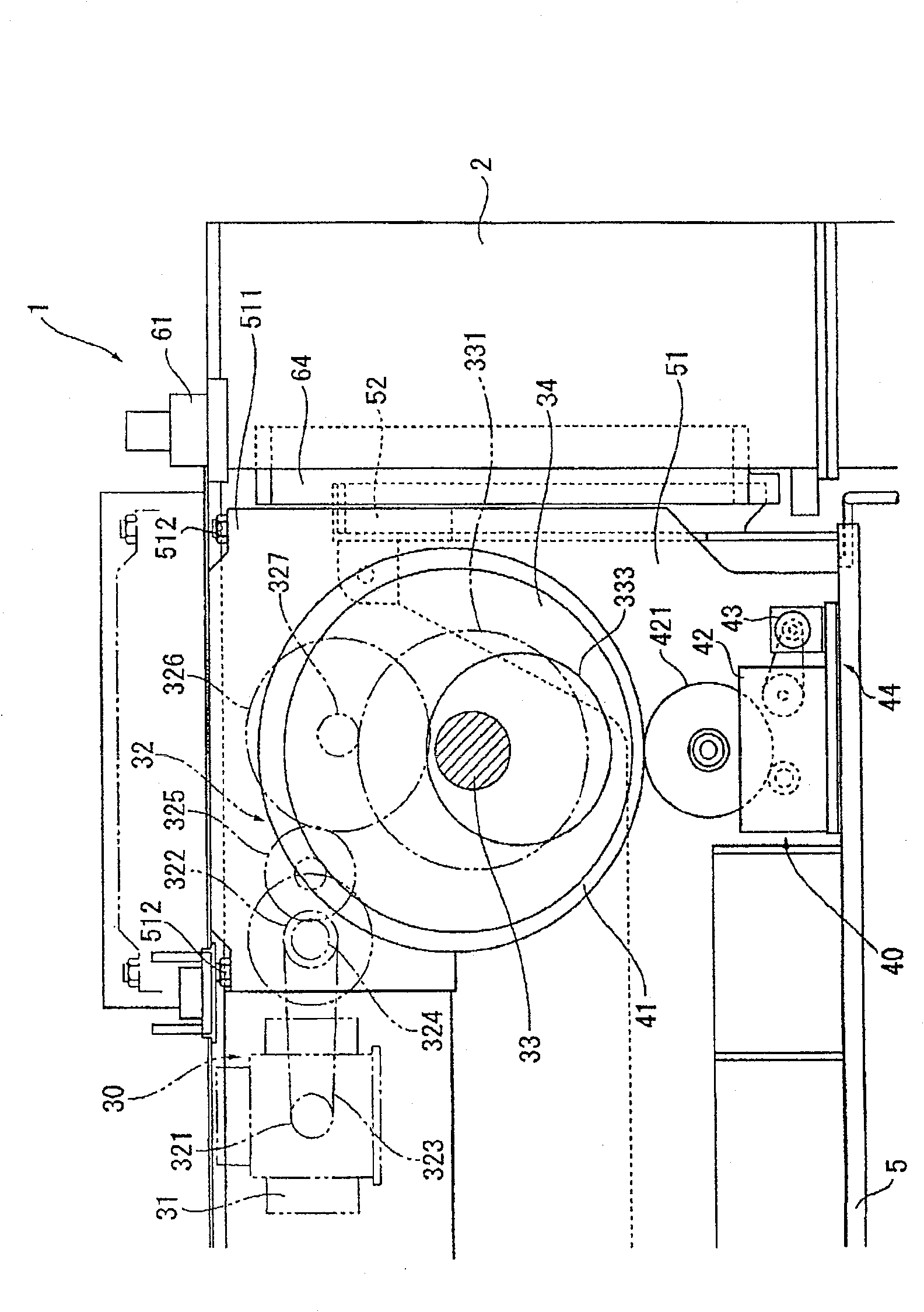

[0029] figure 1 It is an overall view showing a servo press (press machine) 1 according to the first embodiment of the present invention. in figure 1 In the figure, the left side of the figure is the front of the servo press 1, and the right side of the figure is the back of the servo press 1. As that figure 1 As shown, in the servo press 1, four columnar uprights (only two shown) 2 are erected on the upper surface of the base 3, and the upper part of the base 3 is placed in a manner surrounded by 4 uprights 2 Bolster 4. A crown 6 is provided on the upper part of the column 2. In addition, a tie rod 61 is used to fasten and connect the beam 6, the column 2, and the base 3 in a thorn-like manner. A slider 5 is supported on the cross beam 6, and a slider driving device 30 that moves the slider 5 up and down (lifting operation) is also provided.

[0030] If the slider 5 moves up and down under the action of the slider driving device 30, the workpiece is subjected to press process...

no. 2 approach

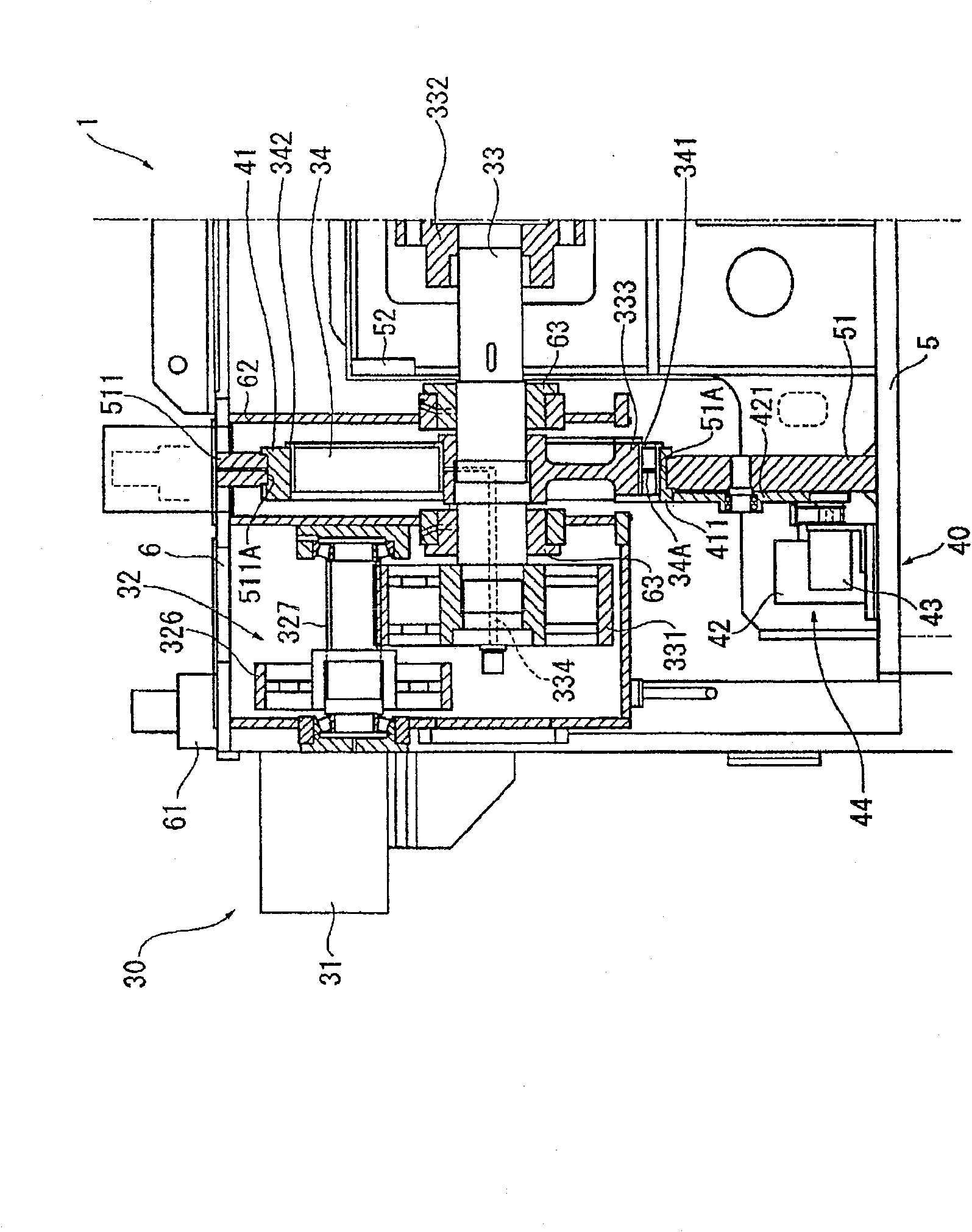

[0064] Next, the second embodiment of the present invention will be described. The second embodiment is the same as the first embodiment except that the installation structure of the rotating ring 34 and the adjustment ring 41 of the servo press 1 of the first embodiment is different from that of the first embodiment.

[0065] Image 6 An enlarged view of the slider driving device 30 of the servo press 1 of the second embodiment is shown. In addition, Figure 7 An enlarged side sectional view of the slider driving device 30 is shown. Like these Image 6 and Figure 7 As shown, the rotating ring 34 of the slider driving device 30 is mounted on the eccentric drum 333 through a spherical roller bearing (rolling bearing) 343. In addition, the adjustment ring 41 is attached to the rotating ring 34 via a cylindrical roller bearing (rolling bearing) 344. In addition, the combination of the spherical roller bearing 343 and the cylindrical roller bearing 344 is adopted in consideratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com