Cotton stalk-drawing crushing harvester

A pulverizer and harvester technology, which is applied in the field of agricultural machinery, can solve the problems of affecting the planting and growth of the next crop, the effect of fertilizer is not obvious, and the rotting speed is slow, so as to achieve significant social and economic benefits, avoid missing pulling, and maintain parallelism and the effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

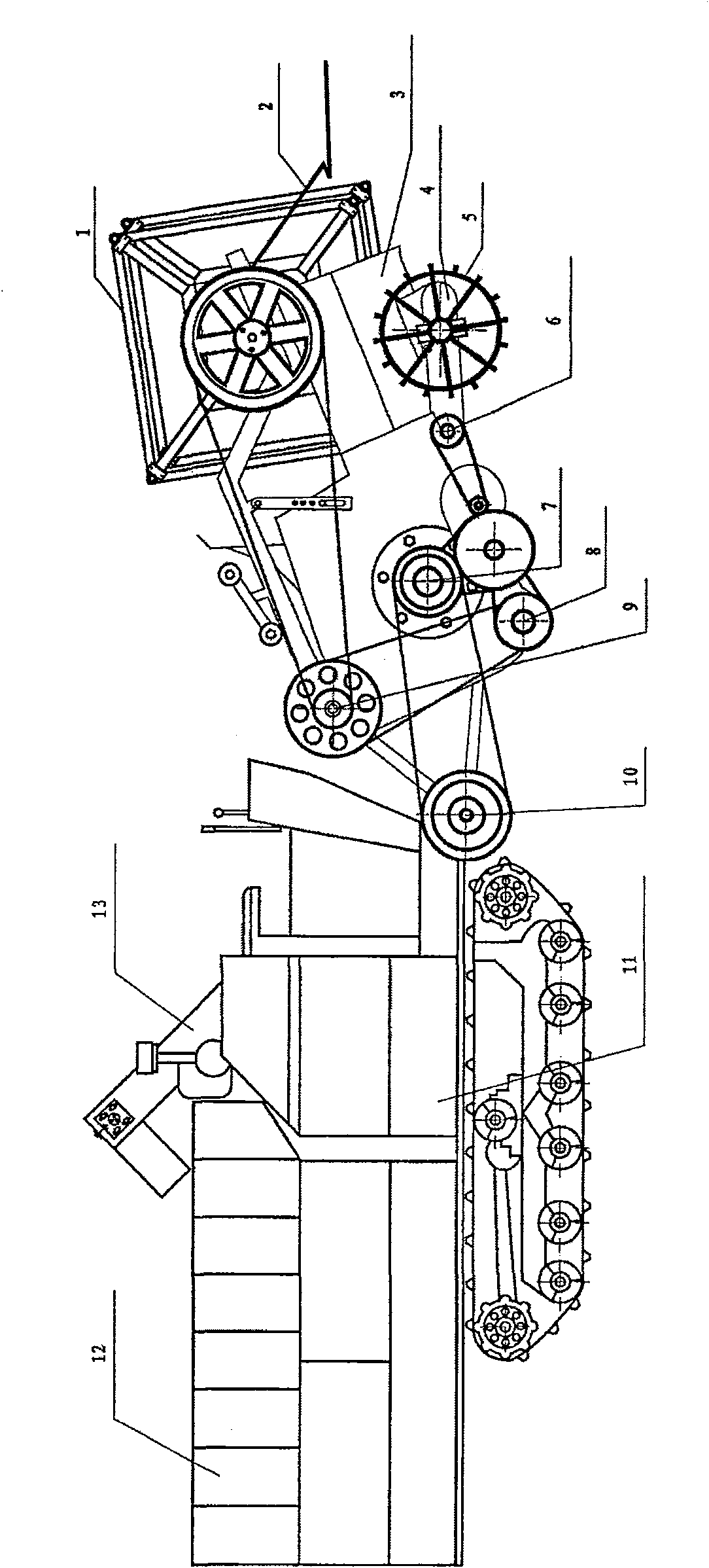

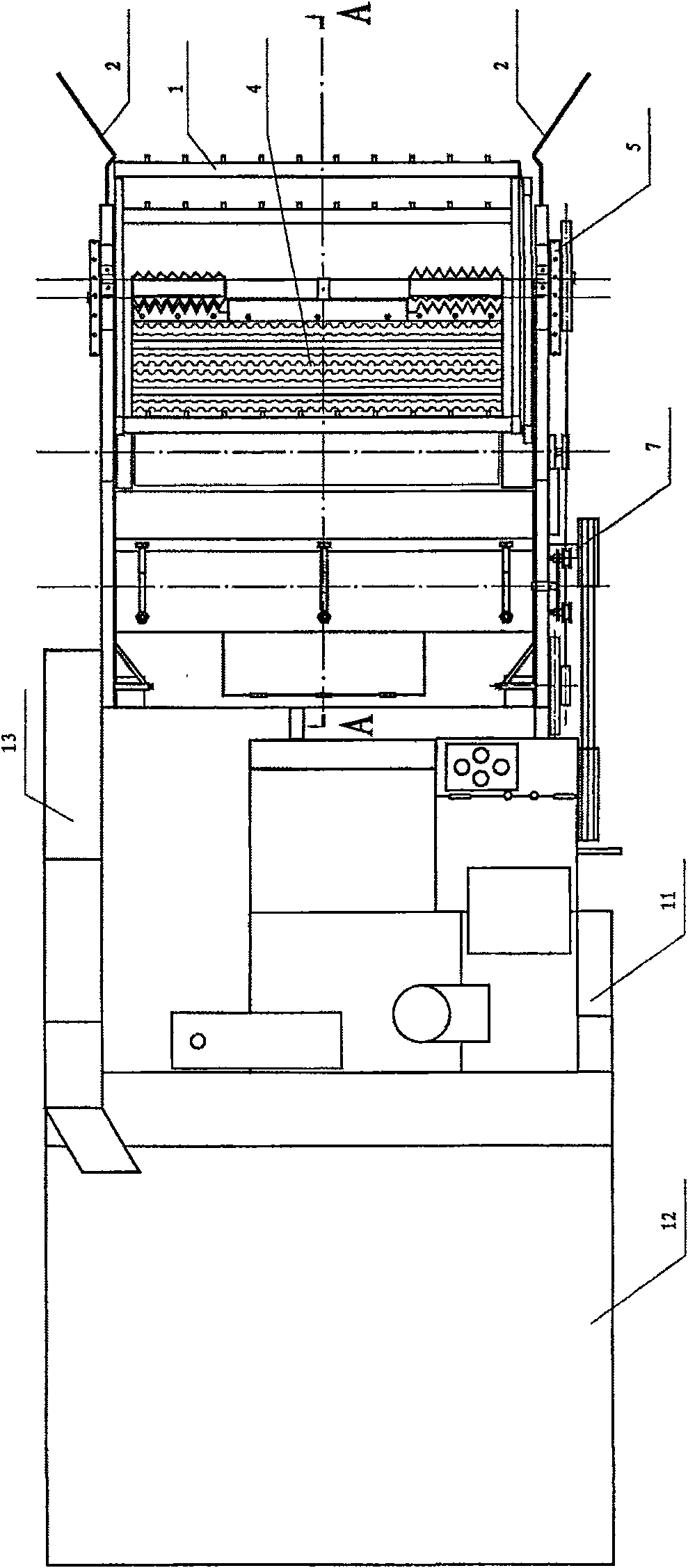

[0021] The cotton stalk crushing harvester is mainly composed of a frame, a reel 1, a grain supporter 2, a grain divider 3, a depth-limiting wheel 5, a floating stalk pulling platform 4, a pulverizer, a conveying trough 13 and a collection platform 12 Composition, grain reel 1, grain holding device 2, grain dividing device 3 are conventionally arranged on the front end of the frame.

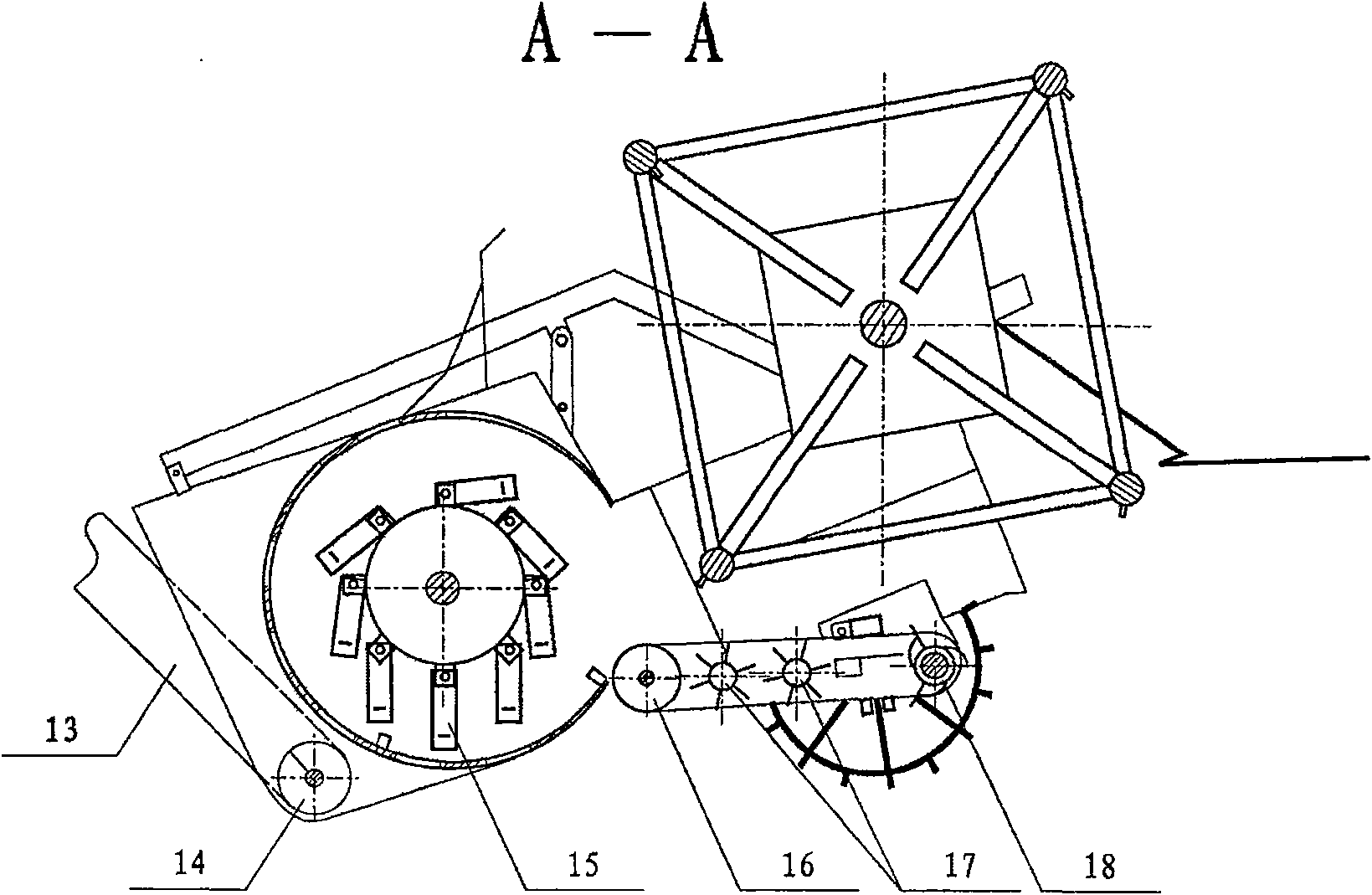

[0022] The floating stalk pulling platform 4 is arranged at a later position below the reel 1. The floating stalk pulling platform 4 is composed of a stalk pulling hob 18, a transmission cleaning wheel 17, a conveying roller 16, a chain transmission box 20, and a side plate 19. The stalk pulling hob 18, two transmission cleaning wheels 17 and one delivery roller 16 are arranged in parallel from front to back in turn, and the two ends of the stalk pulling hob shaft 29, the transmission cleaning wheel shafts 27, 28 and the delivery roller shaft 6 respectively pass through The double-row self-aligni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com