Double-side paper feeding device

A double-sided, paper-feeding technology, applied in the field of paper-feeding devices, can solve problems such as distortion of scanning results, inability to accurately control the movement of paper 10, paper jams, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

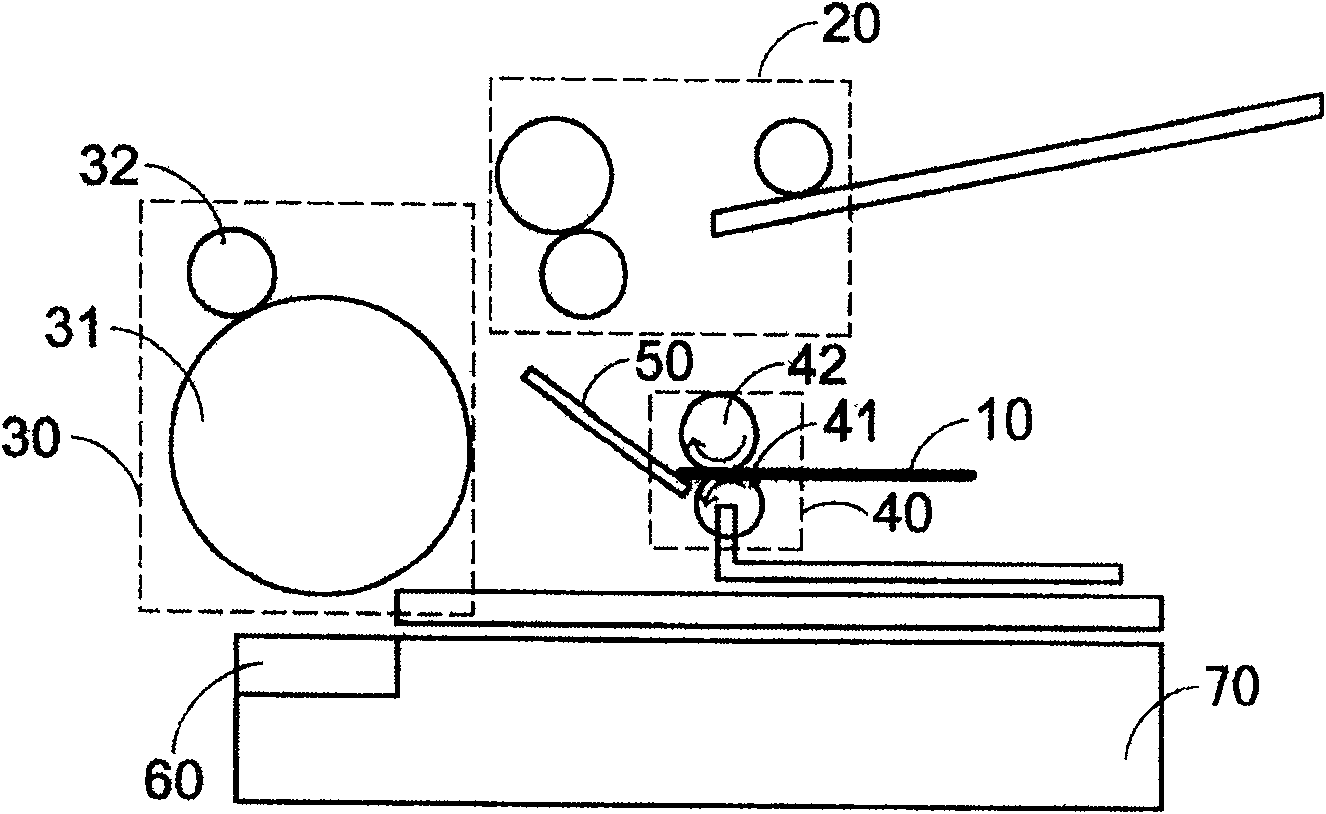

[0023] The implementation content of the present invention is to provide a double-sided paper feeding device, which can be applied to scanning devices such as facsimile machines, printers and scanners, to automatically turn over paper to complete double-sided scanning. see figure 2 , which is a schematic diagram of the double-sided paper feeding device of the present invention. Such as figure 2 As shown, the double-sided paper feeding device includes: a paper fetching module 100 , a paper control roller module 120 , a paper input and output module 140 , a first paper feeding channel 160 , and a second paper feeding channel 180 . The double-sided paper feeding device of the present invention can optionally be provided with an auxiliary paper-carrying module 200 . Wherein, the paper picking module 100 includes a paper picking roller 102 and a paper separating roller 104 . The paper control roller module 120 includes: a first paper control roller 122 , a second paper control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com