Original soft clay hollow cylinder sample inner core cutting device

A technology for hollow cylindrical samples and soft clay, applied in the field of core cutters for hollow cylindrical samples of undisturbed soft clay, can solve problems such as hindering drilling, increasing sample disturbance, disturbance, etc., to reduce propulsion resistance and avoid secondary The effect of secondary adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

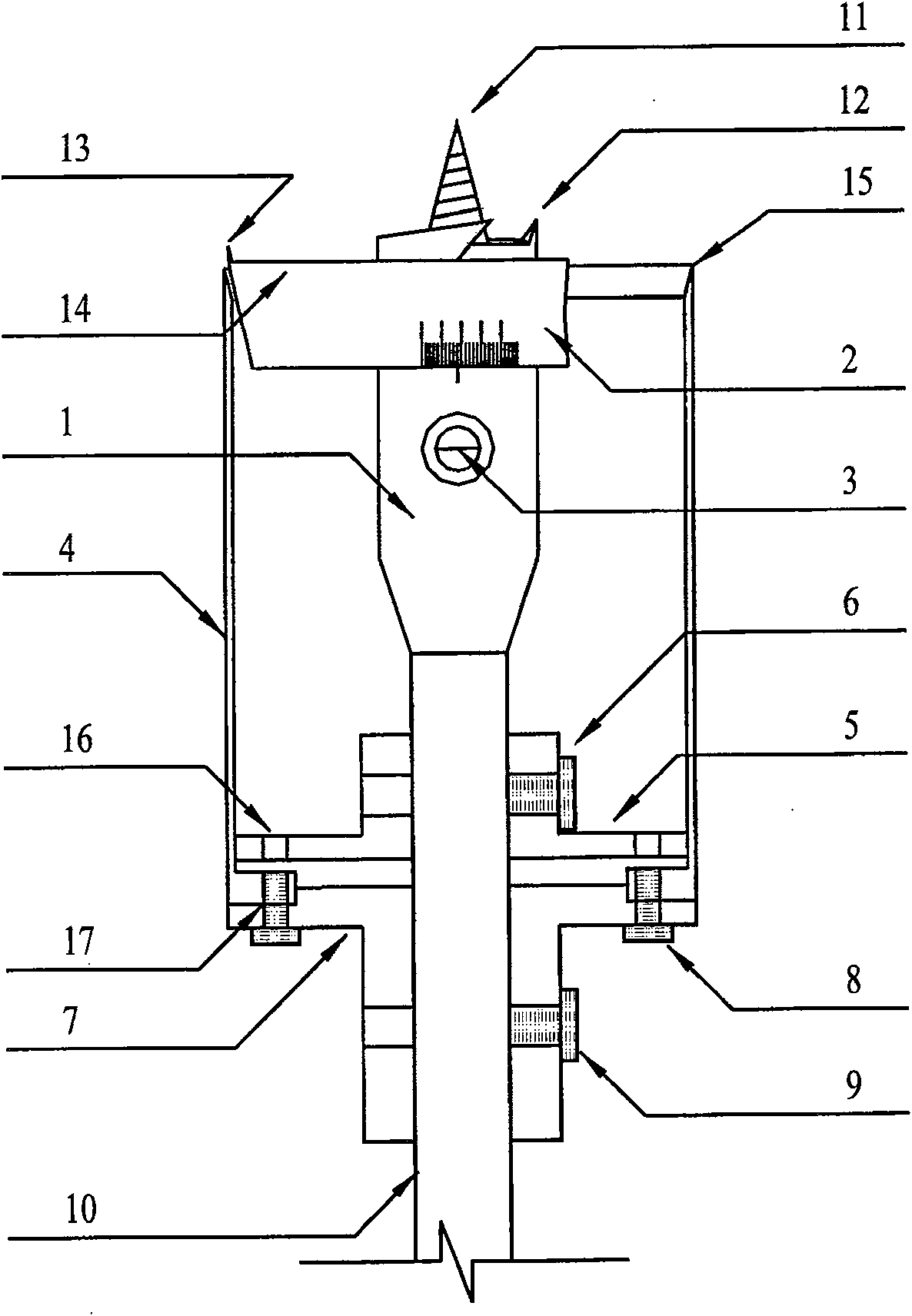

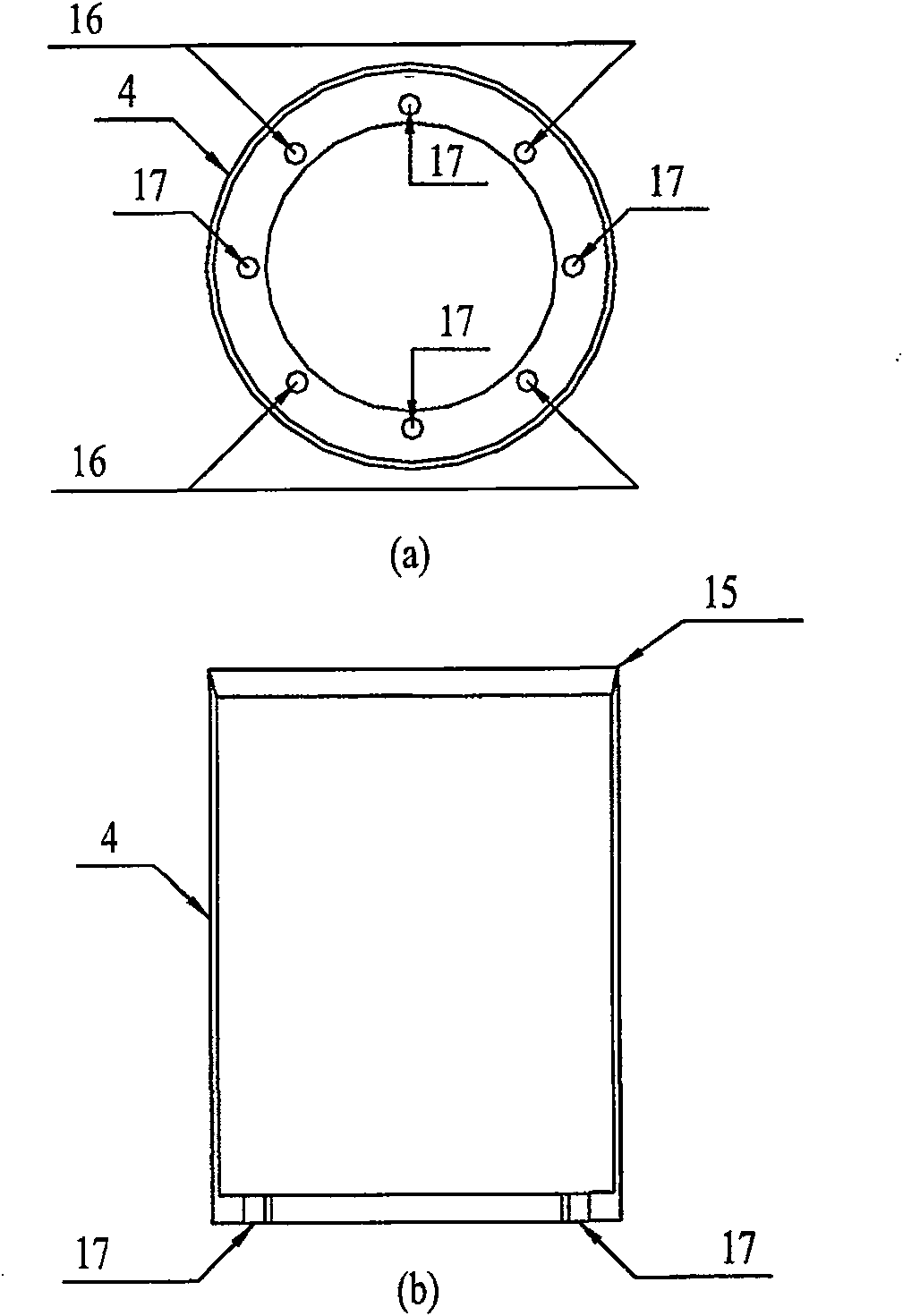

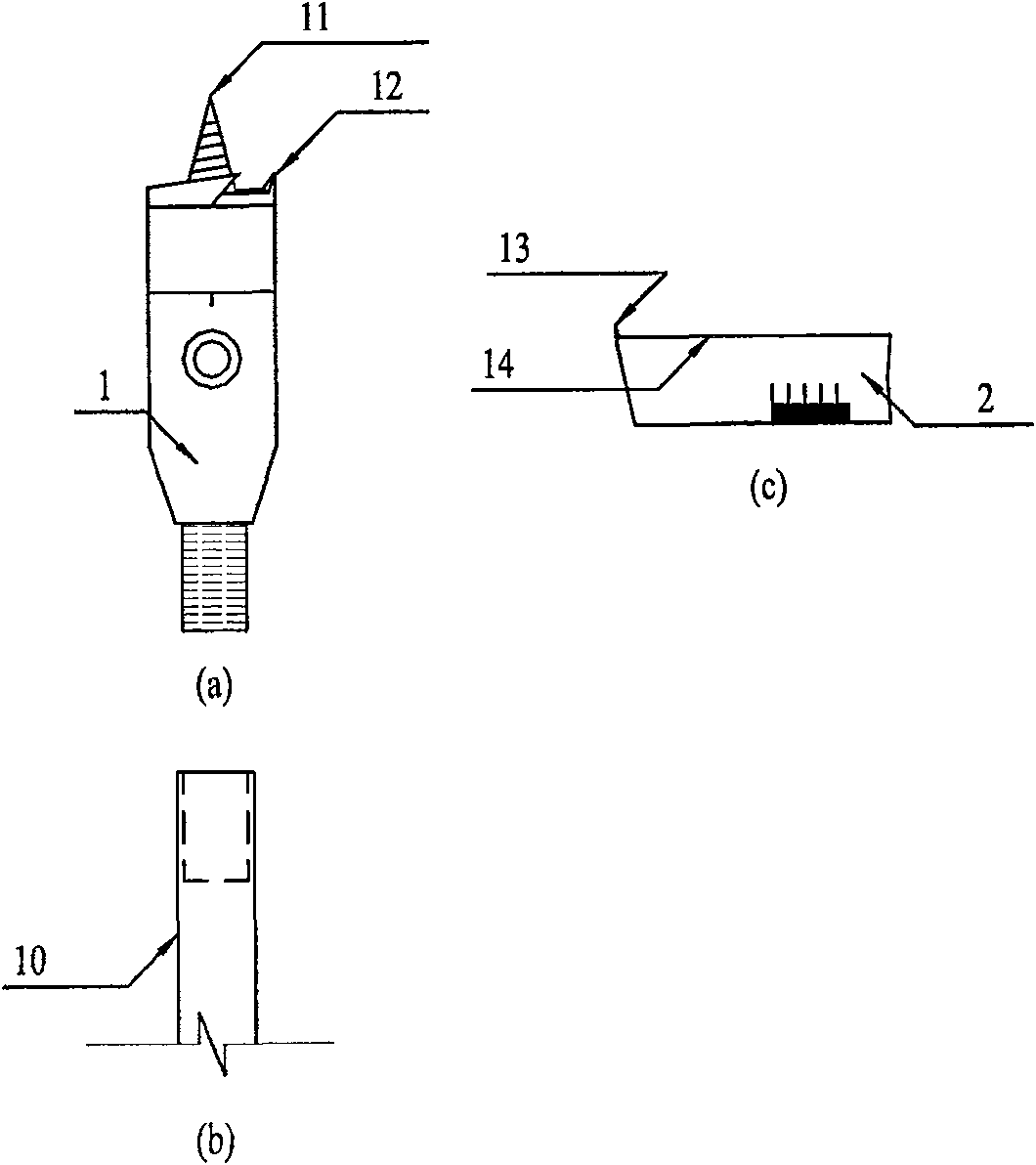

[0022] Such as figure 1 , 2 As shown in , 3, 4, 5, and 6, the inner core cutter of the original soft clay hollow cylindrical sample has a casing 4, the upper end of the casing 4 is provided with a cutting edge 15, and the lower end of the casing 4 is positioned through the casing bottom bracket-casing Screw 8 and casing-casing bottom bracket connecting screw hole 17 are connected with detachable casing bottom bracket 7, and detachable type casing bottom bracket 7 is provided with detachable soil holder 5, and detachable soil holder 5 is provided with release Pressure hole 16, main drill bit 1 is arranged in the middle of casing 4, and main drill bit 1 is made up of auger bit 11, inner edge blade 12, and is connected with drill pipe 10, and drill pipe 10 passes through detachable soil holder 5, detachable casing Bottom support 7 is respectively fixed by soil support-drill pipe positioning screw 6 and casing bottom support-drill pipe positioning screw 9. The detachable blade pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com