Repairing method for radial tire crown explosion

A radial tire, tire crown technology, applied in tires, other household appliances, household appliances and other directions, can solve the problems of shortening the service life of tires, increasing the cost of replacing new tires, etc., to achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] As shown in the figure, the radial tire crown burst repair is carried out as follows:

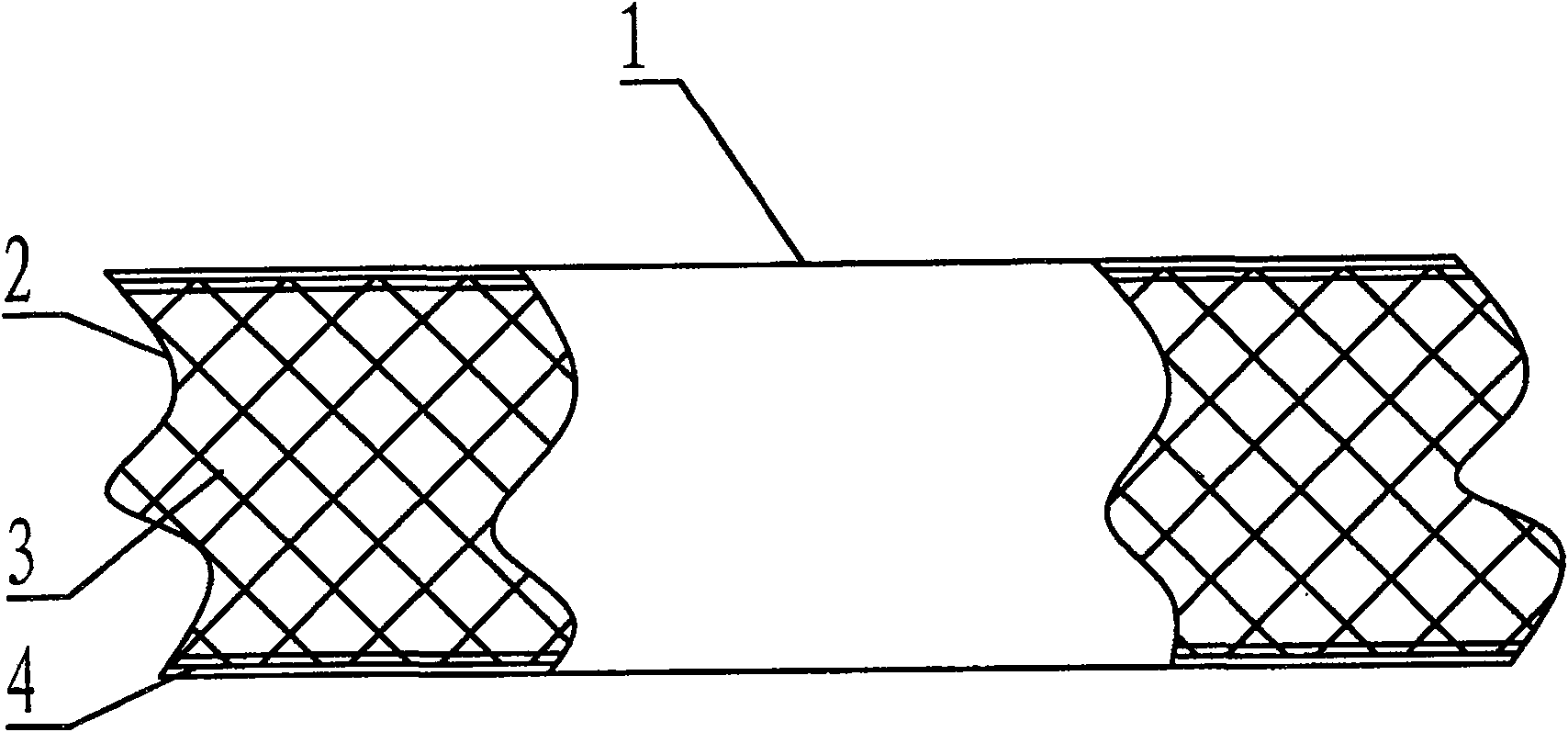

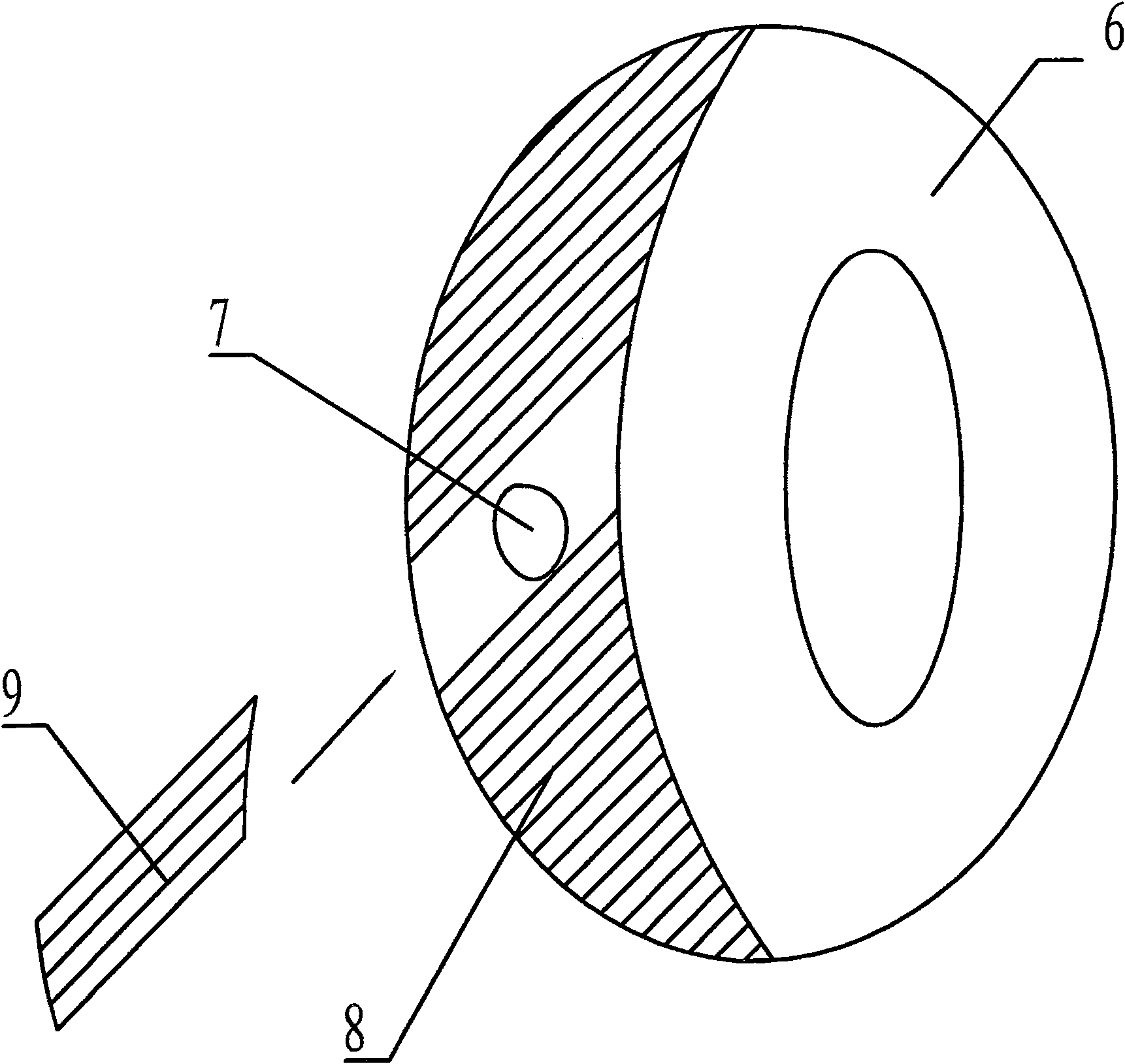

[0022] a. Along the circumference, near the sidewall of the tire shoulder edges, the crown surface 1 containing two layers of belt layer steel wire 3 is integrally cut away from the carcass 6 with a cutter;

[0023] b. Pick out the two layers of belt steel wires 3 with two broken ends 2 damaged at the wound on the crown surface 1, and then remove the explosion-proof belt steel wires 4 arranged along the circumferential direction of the crown near the tire shoulders, Cut off and reject according to the length of the belt layer steel wire 3 that has been removed;

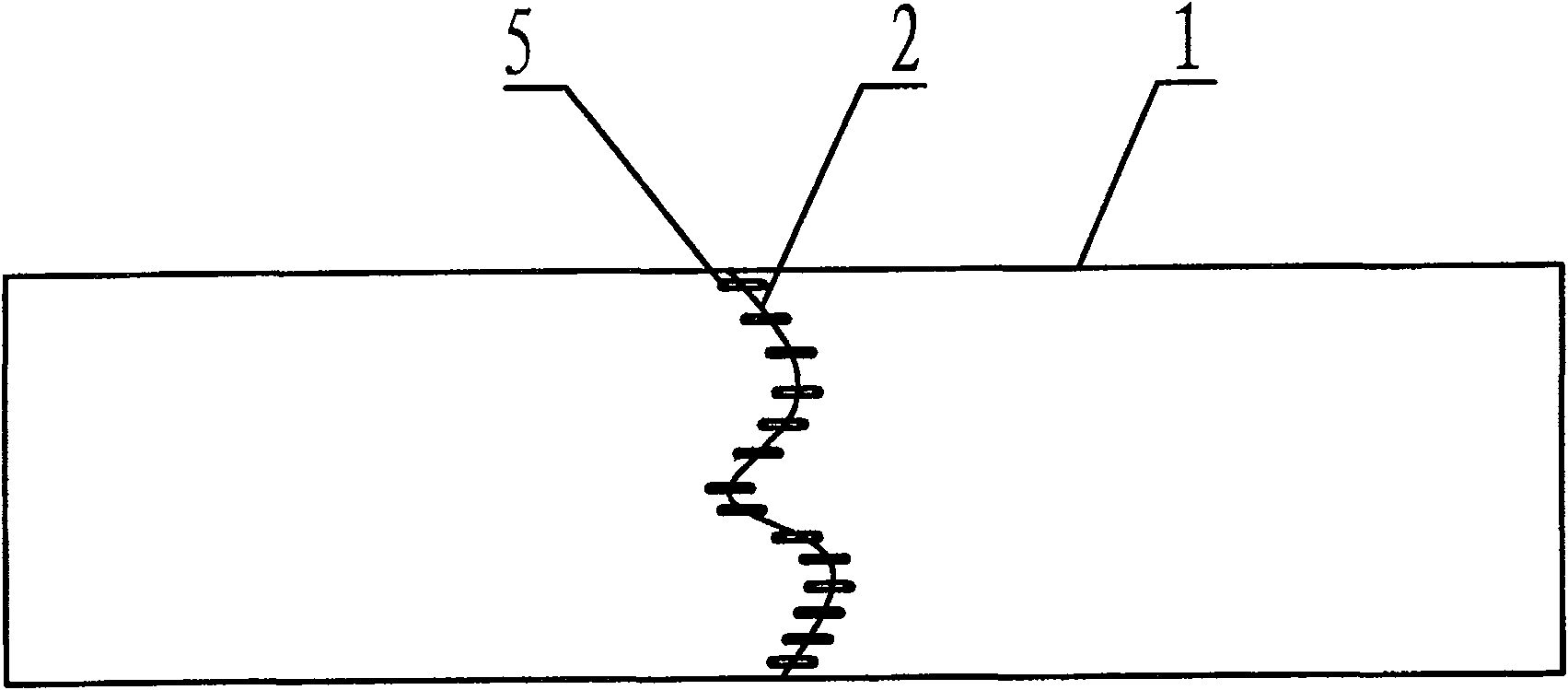

[0024] c. After grinding the crown surface 1 as a whole, use the connecting rivet 5 to connect the two broken ends 2 at the wound of the crown surface 1 according to the original burst shape, apply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com