Thyristor switched capacitor high voltage valve test device and method

A thyristor switching and testing device technology, applied in the field of measurement and testing, can solve the problems of inability to take into account the TSC high-voltage valve operation test and overcurrent test, etc., and achieve the effects of reducing the capacity of the test power supply, the overall circuit structure is simple, and improving the safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

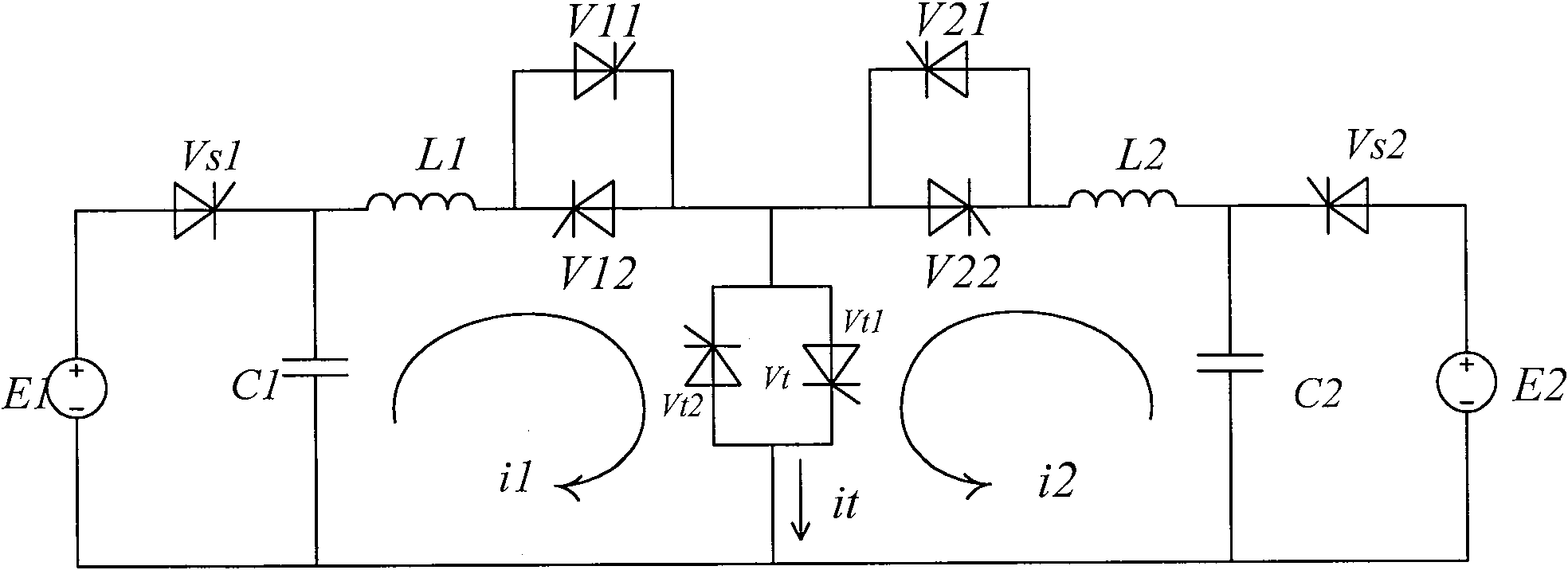

[0017] The principle of the topological structure of the thyristor switching capacitor high-voltage valve test device of the present invention is as follows: figure 1 , where E1 is a high-current DC voltage source, E2 is a high-voltage DC voltage source, and Vt is the tested TSC valve. The tested valve Vt is composed of a forward valve Vt1 and a reverse valve Vt2 in antiparallel connection, and C1 is Large current oscillation capacitor, L1 is a large current oscillation reactor, C2 is a high voltage oscillation capacitor, L2 is a high voltage oscillation reactor; high current oscillation capacitor C1 and high current oscillation reactor L1, high voltage oscillation capacitor C2 and high voltage oscillation Reactor L2 constitutes two relatively independent oscillating circuits. Vs1 is a high current power control valve, Vs2 is a high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com