Chain guide structure of mining machine

A guiding structure and chain technology, applied in the direction of slitting machinery, conveyors, propulsion, etc., can solve the problems of guide card wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

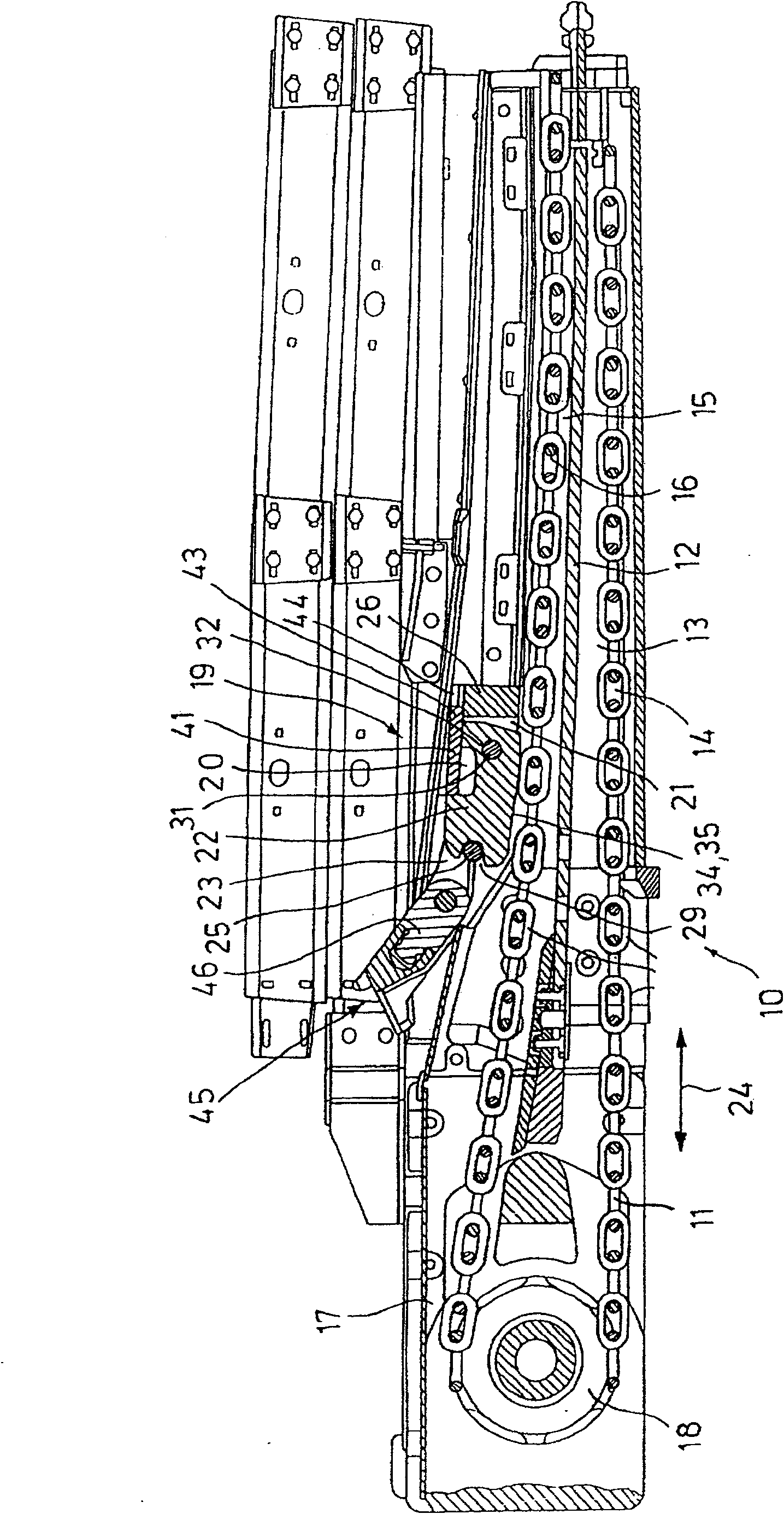

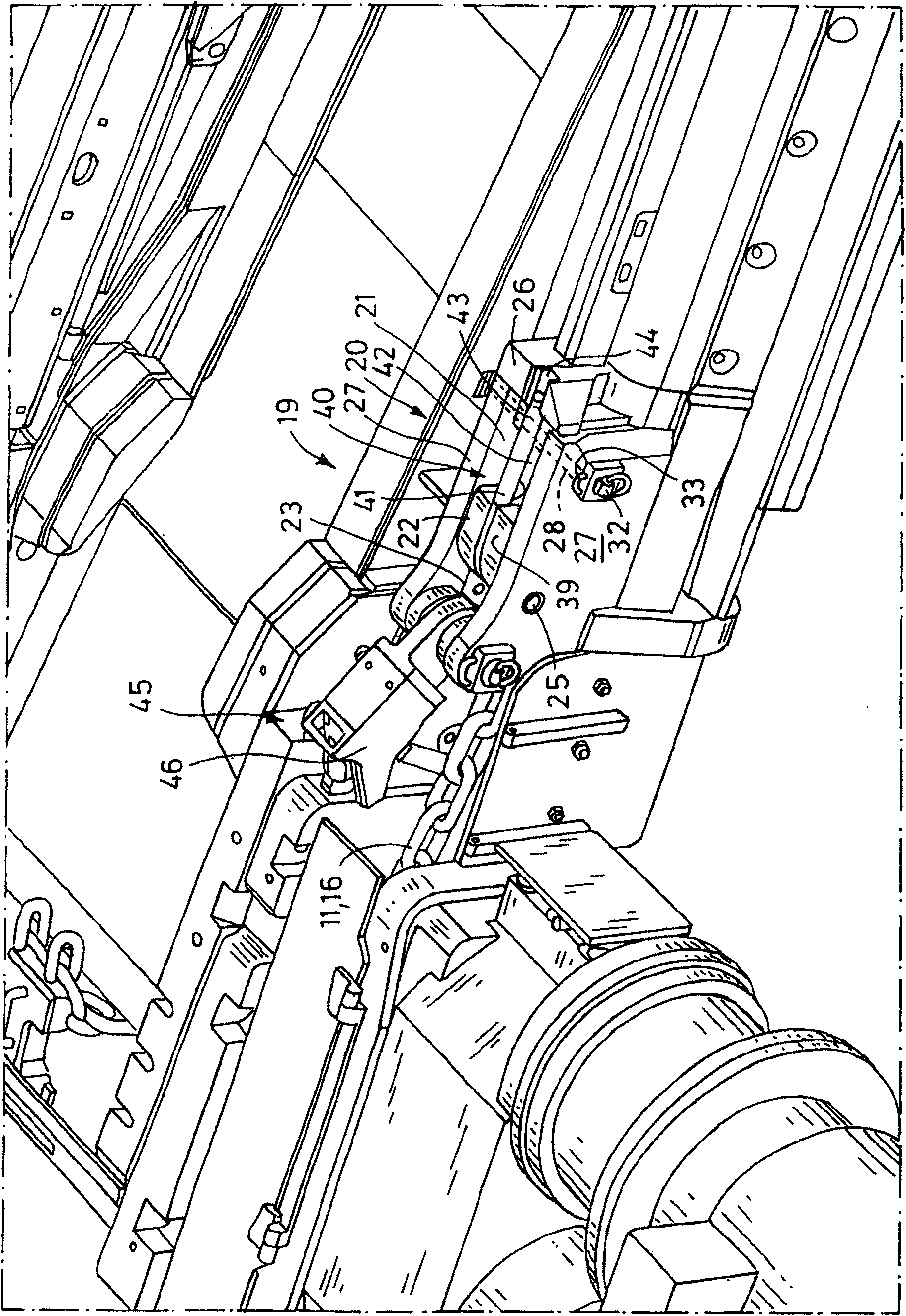

[0017] A chain guide, indicated generally at 10 in the drawing, is used to guide a drive chain 11 of a coal plow used in underground mining for extracting coal.

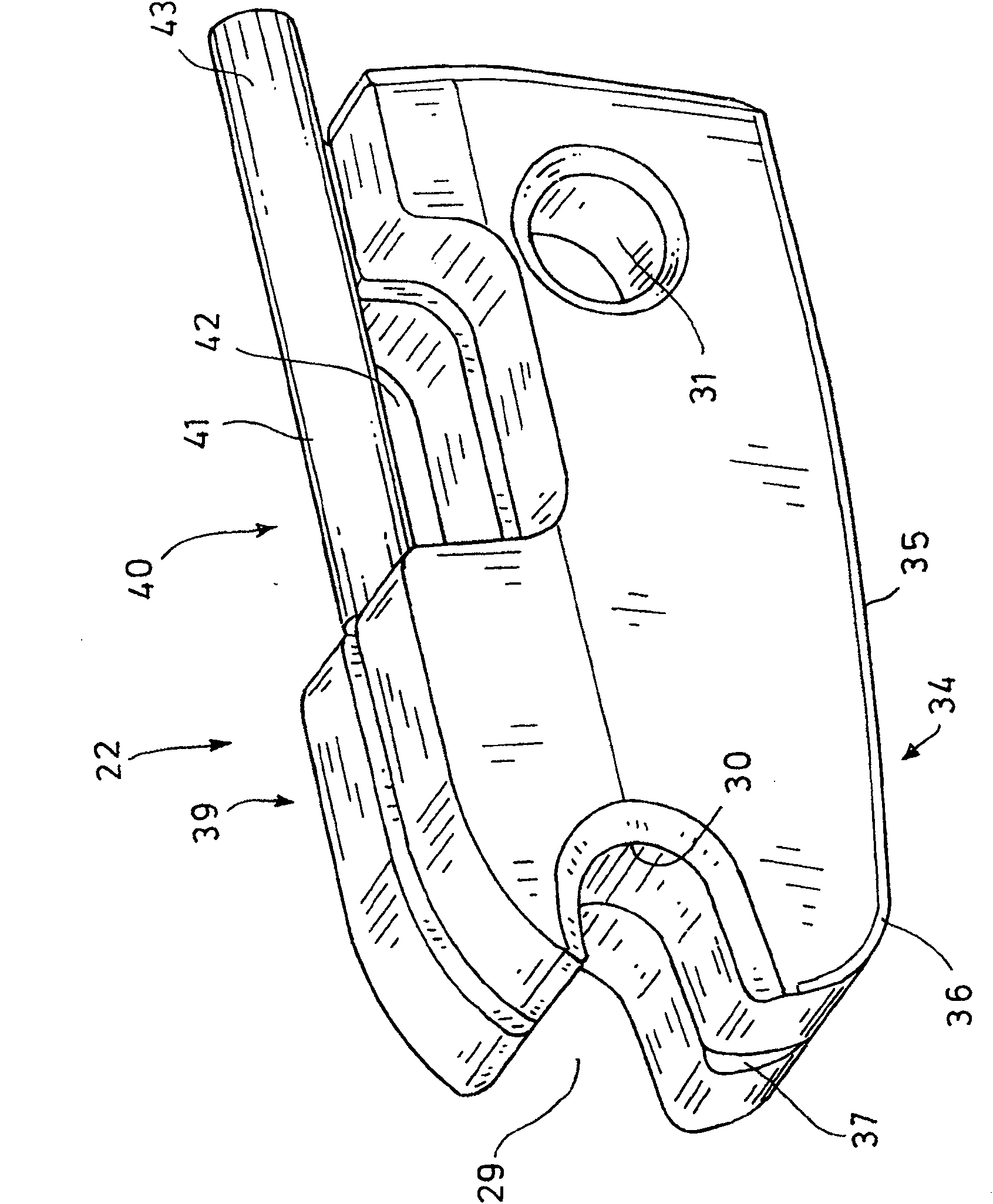

[0018] The chain guide 10 has in the plow chain guide 12 a first chain groove 13 for the load-bearing leg 14 of the drive chain and a second chain groove 15 which supports the non-load-bearing leg 16 of the drive chain. Attached to the end regions of the chain grooves 13, 15 is a transmission station 17 with a drive sprocket 18, which is wound by the drive chain 11 and is used to pull the chain through the chain grooves, as is known. In the transition area 19 between the second chain groove 15 and the transmission station 17, establish a chain guide 20 for the non-bearing branch 16 of the transmission chain 11. This chain guide mainly consists of an upper and lower opening mounting seat 21 and It consists of a pressure plate 22 fitted inside it and locked in its installed position. Mounting seat 21 passes through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com