Chemical method for coating nickel and zinc on multi-wall nano carbon tube surface

A multi-wall carbon nanotube and carbon nanotube technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of high chemical potential of zinc and no discovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

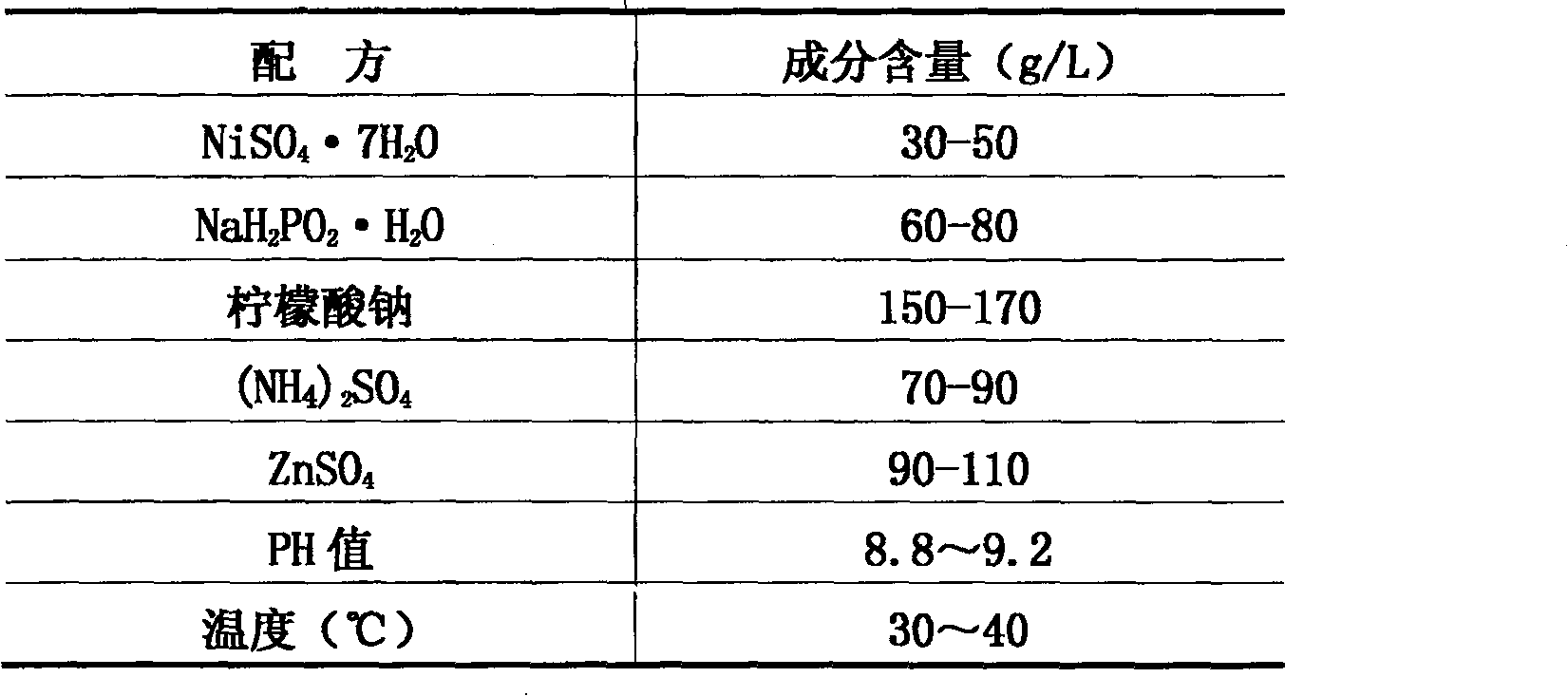

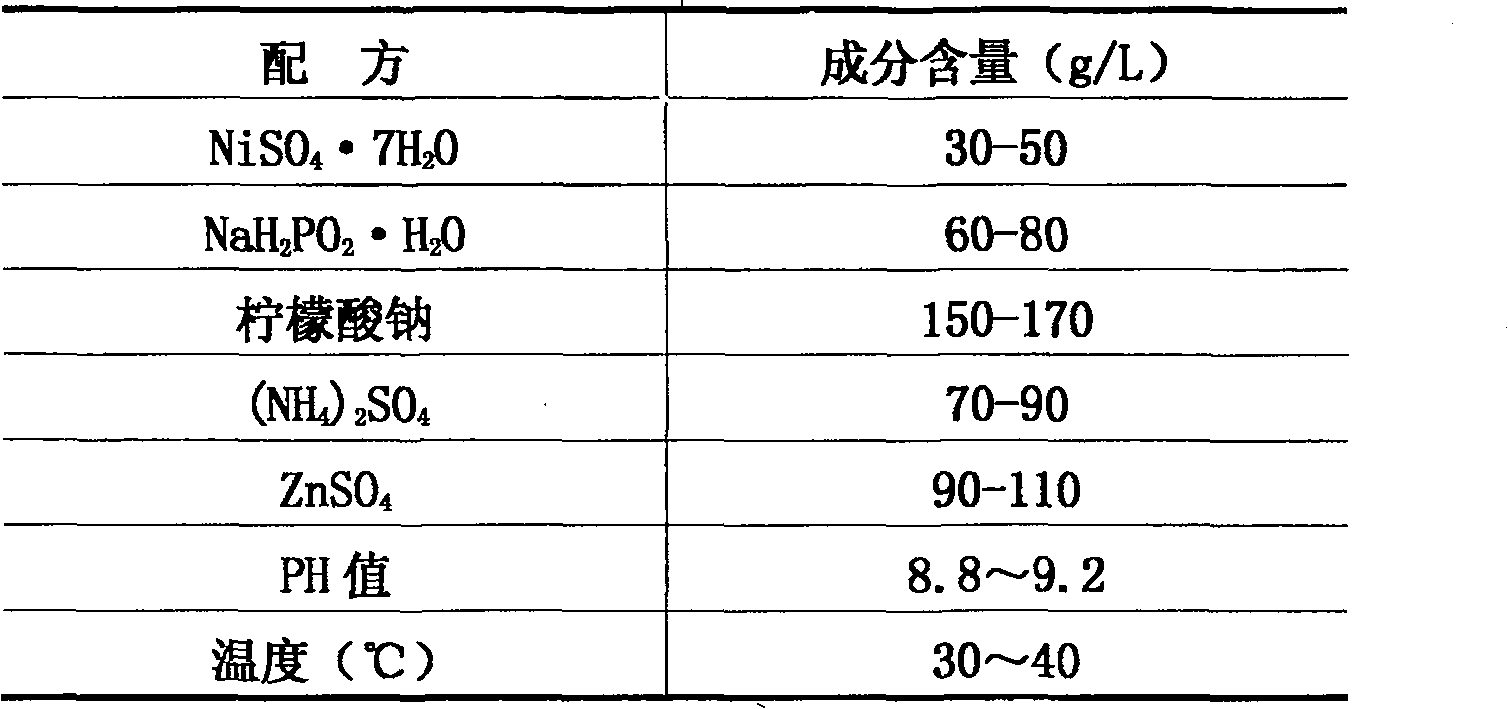

[0017] The process steps of electroless nickel-zinc plating on the surface of multi-walled carbon nanotubes are as follows:

[0018] 1. Purification treatment: use lye to remove fatty substances on the surface of carbon nanotubes. Put the carbon nanotubes into NaOH aqueous solution with a concentration of 1-3mol / L, oscillate in an ultrasonic oscillator to fully disperse, the ultrasonic mode is 30 seconds per ultrasonic, stop for 30 seconds; heat for 0.2-2 hours, cool to room temperature; use deionization Wash with water until neutral; dry the washed powder in a vacuum oven;

[0019] A better value is: put carbon nanotubes into NaOH aqueous solution with a concentration of 2mol / L, oscillate in an ultrasonic oscillator to fully disperse, the ultrasonic mode is 30 seconds of ultrasonication, stop for 30 seconds; heat for 1 hour, and cool to room temperature.

[0020] 2. Add 5-15 grams of purified carbon nanotubes to 250mL concentrated nitric acid for oxidation treatment, heat to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com