Full-automatic small type block machinery having environment-protecting and energy-saving functions

A block forming machine, environmental protection and energy-saving technology, applied in the direction of ceramic forming machine, ceramic forming workshop, supply device, etc., can solve the problems of high production cost, unsatisfactory work performance, etc., improve accuracy, reduce failure rate, The effect of meeting the needs of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

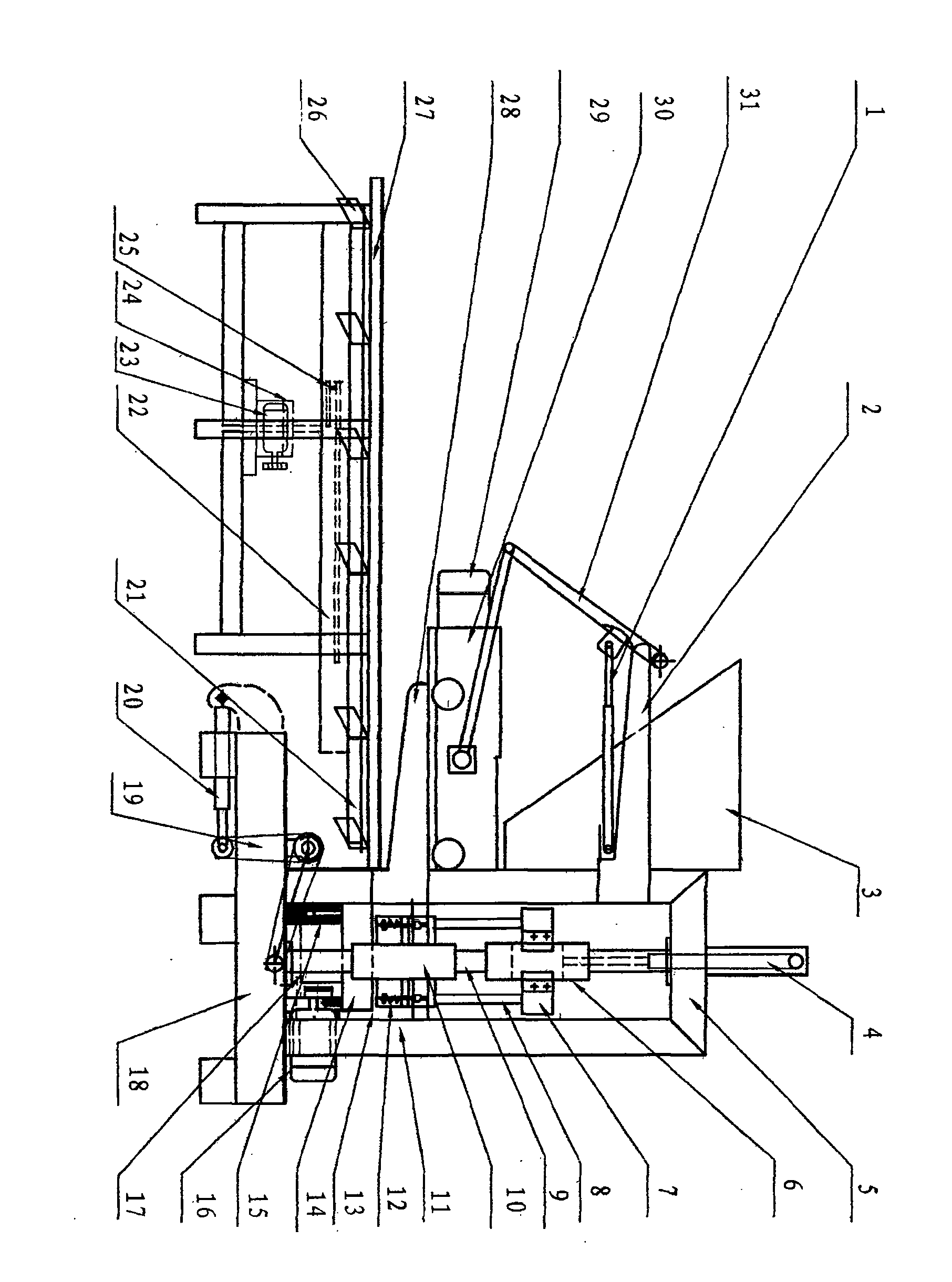

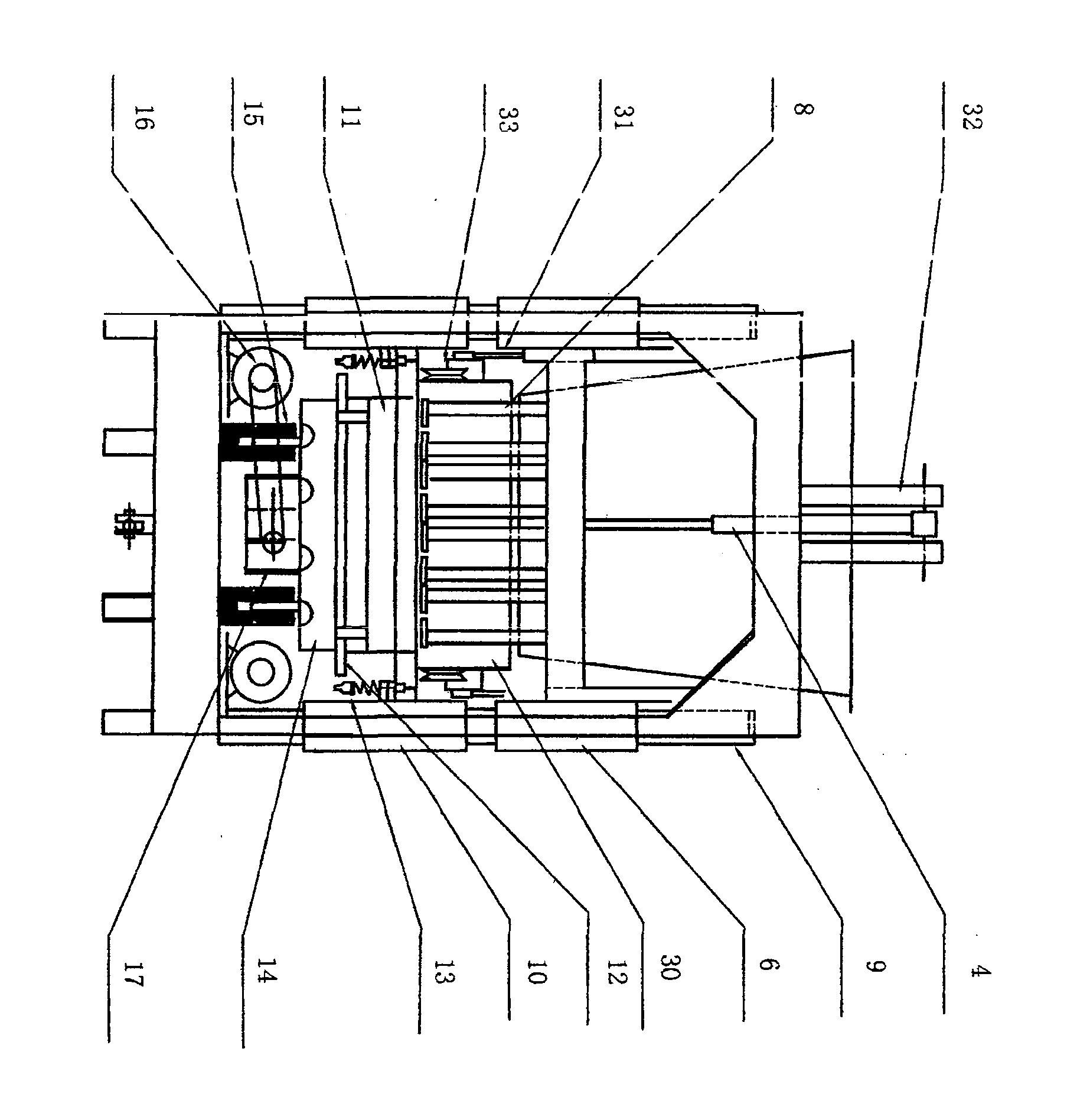

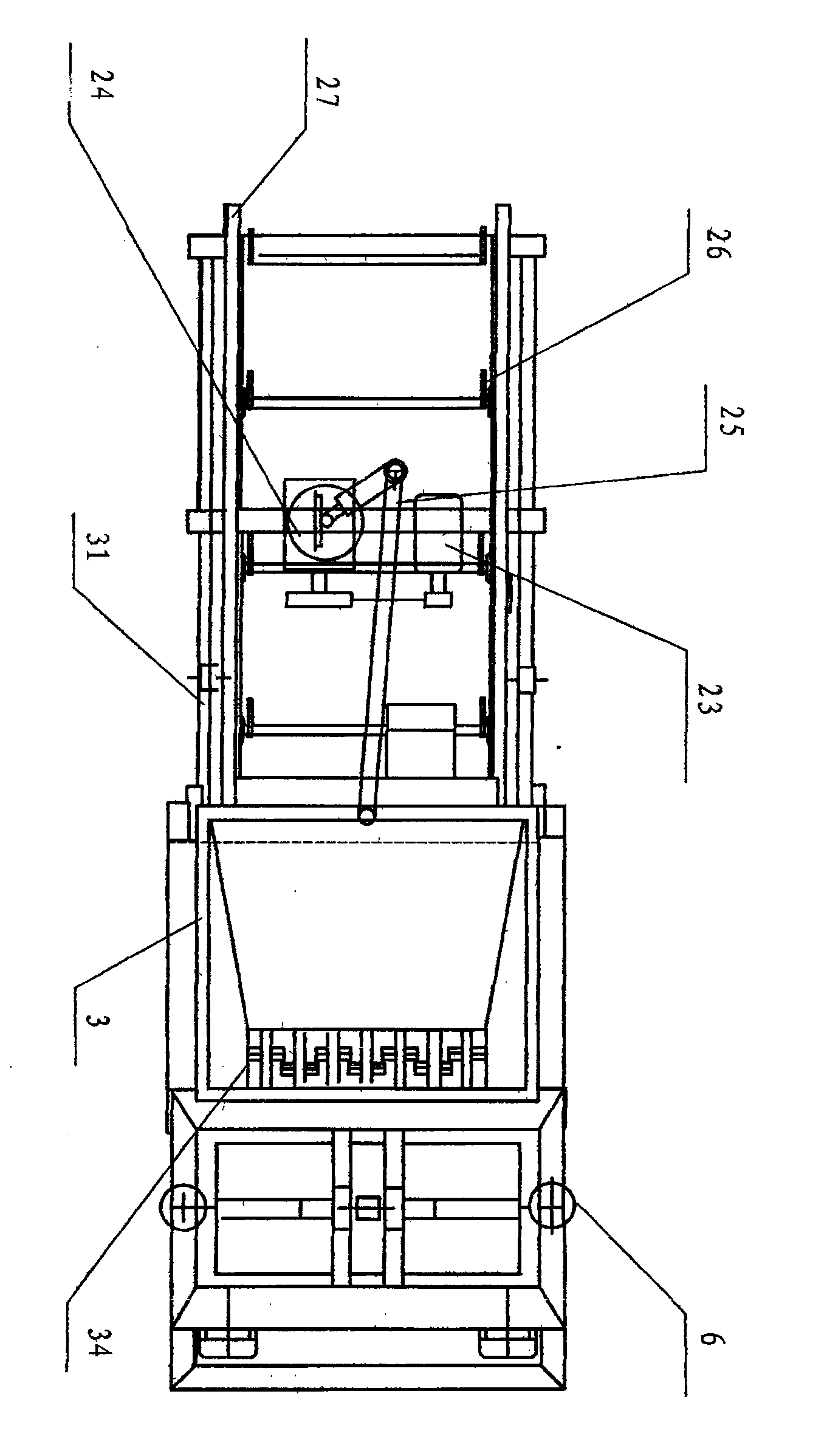

[0023] exist figure 1 , figure 2 , image 3Among them, the machine 5 and the machine base 18 are both welded by channel steel, and the two are formed into a rectangular frame by welding. . A material storage module system, a distribution module system, a block forming module system, a hydraulic demoulding module system and a feeding plate module system are installed in the above-mentioned rectangular frame. The material storage module system is arranged at the uppermost part of the rectangular frame, and the distribution module system is arranged at the lower part of the material storage module system, and the two are connected through the discharge pipe of the material storage box; The discharge pipe of the distribution box is connected with the distribution module system; the hydraulic demoulding module system is set at the lower part of the block forming module system, and is connected with the block forming module system through the crank connecting rod; the feeding pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com