Bag filter outer frame angle structure

A bag filter and outer frame technology, which is applied in the field of air purification, can solve the problems of poor resistance to twisting and deformation, low joint strength at corner joints, poor sealing performance, etc., and achieve enhanced support strength and resistance to twisting and deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

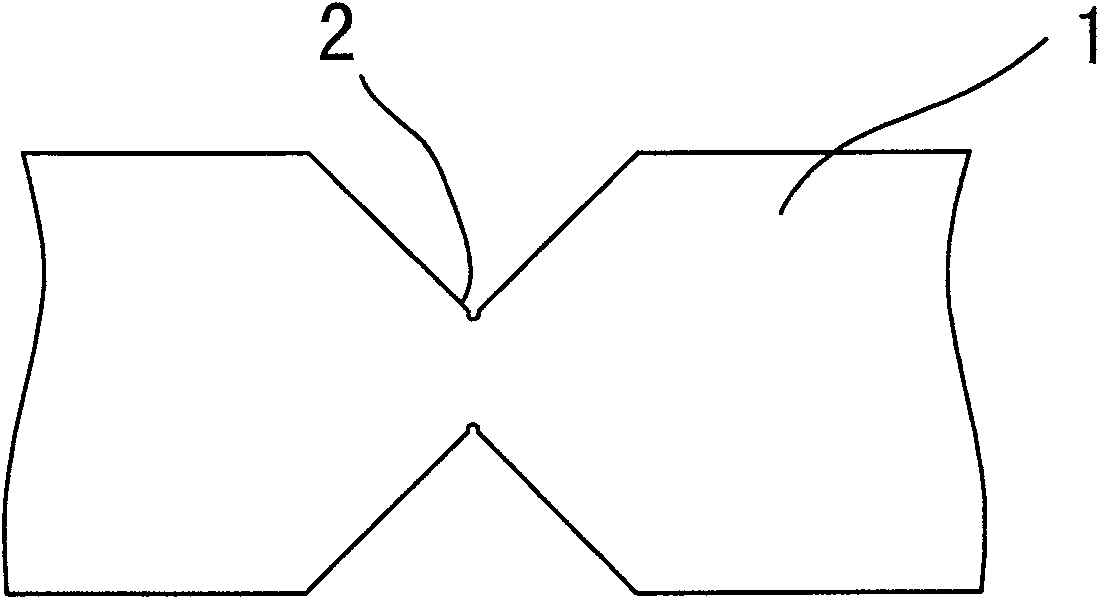

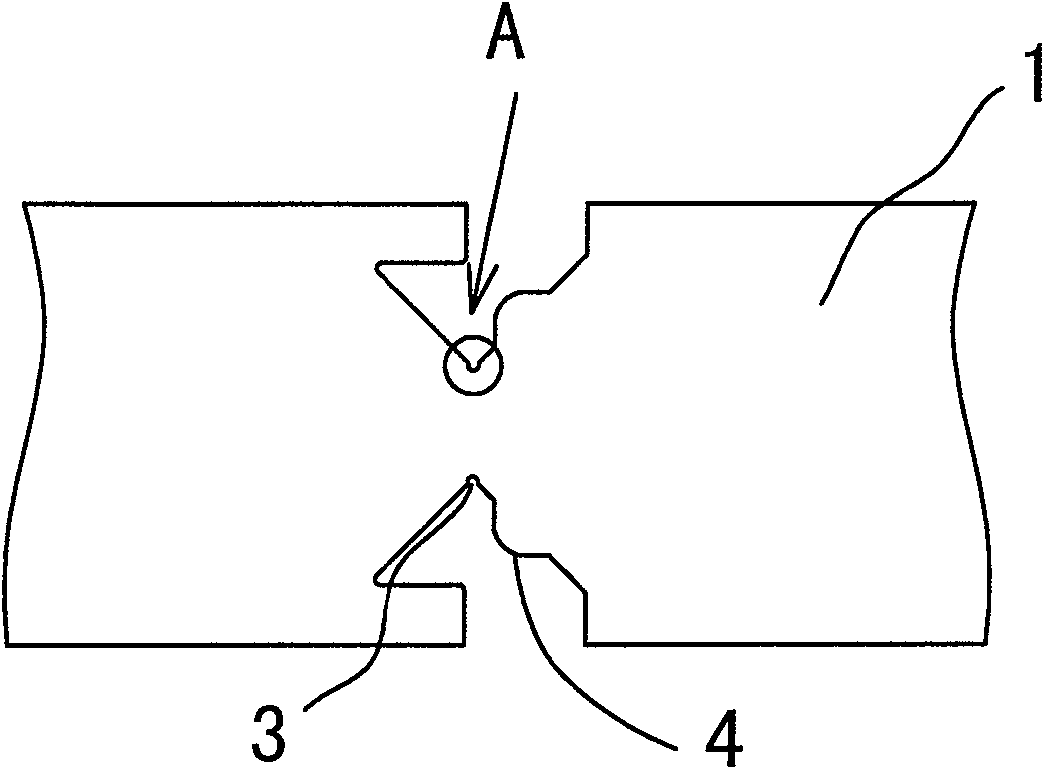

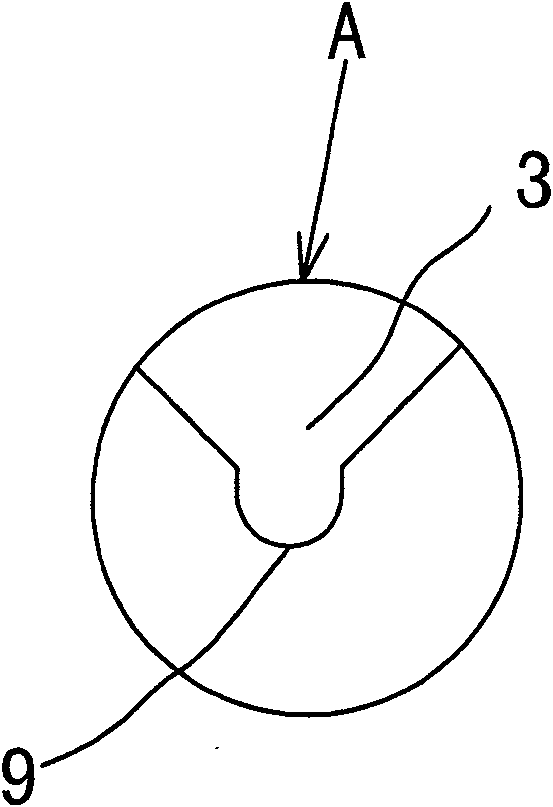

[0023] Such as Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, a bag filter outer frame knuckle structure is composed of a first beveled groove body 5 and a second beveled groove body 6 folded and folded at the beveled edge, wherein the bottom surface of the first beveled groove body 5 and the bottom surface of the first beveled groove body The bottom surface of the second beveled groove body 6 is an integrated structure, and the two side walls of the first beveled groove body 5 and the second beveled groove body 6 are all composed of a vertical outer wall 8 and an "L" shaped The inner wall 7 is composed of the outer wall 8 on both sides formed by a section of extension body flanging on both sides of the bottom surface of the tank body, and the "L" shaped inner wall 7 on both sides is formed by a section of extension body flanging on the upper part of the outer wall 8 of the tank body, and the "L" shaped inner wall The vertical section of 7 is parallel to the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com