Flow control valve

A technology of flow control valves and valve components, applied in the direction of engine control, valve details, valve devices, etc., can solve problems such as leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

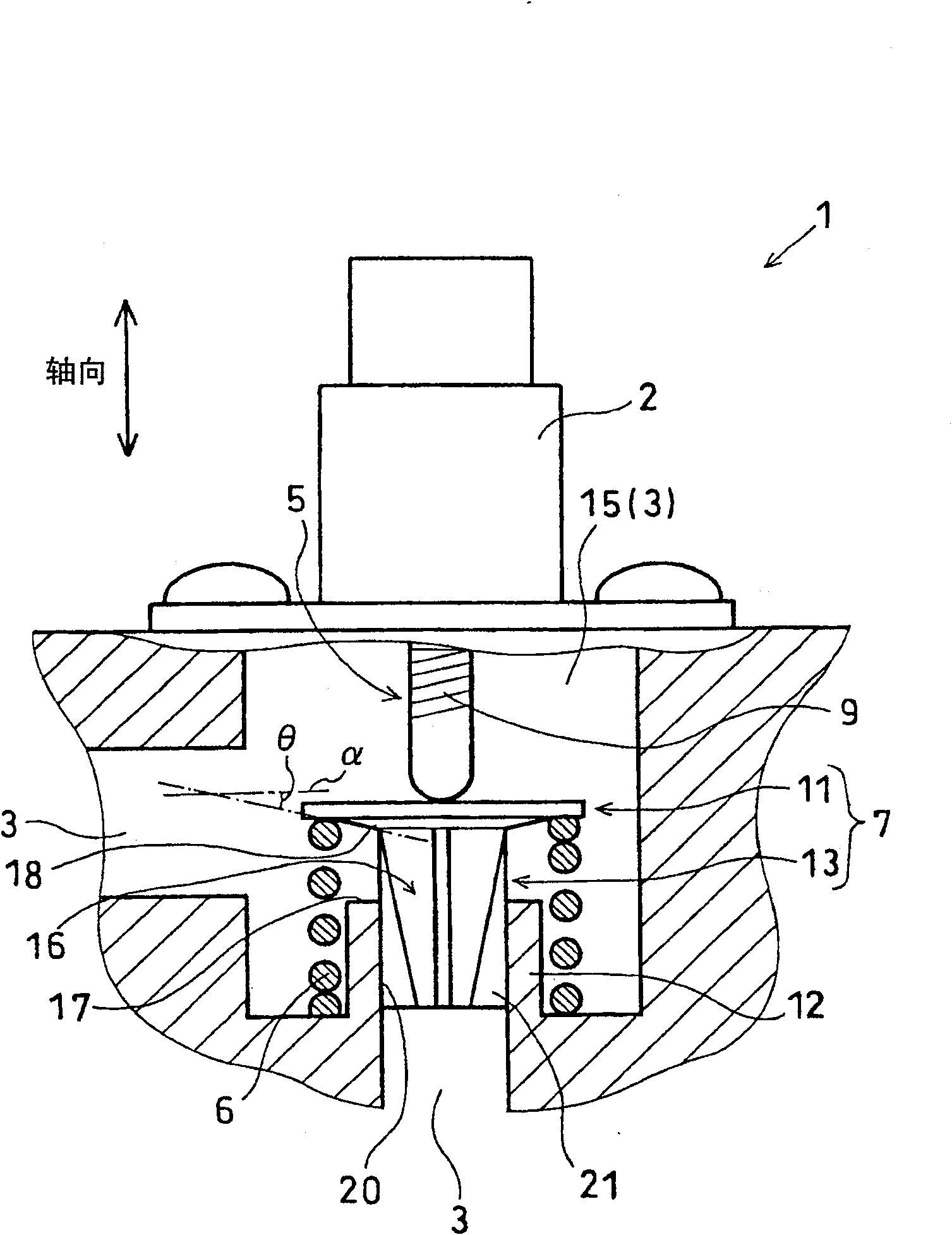

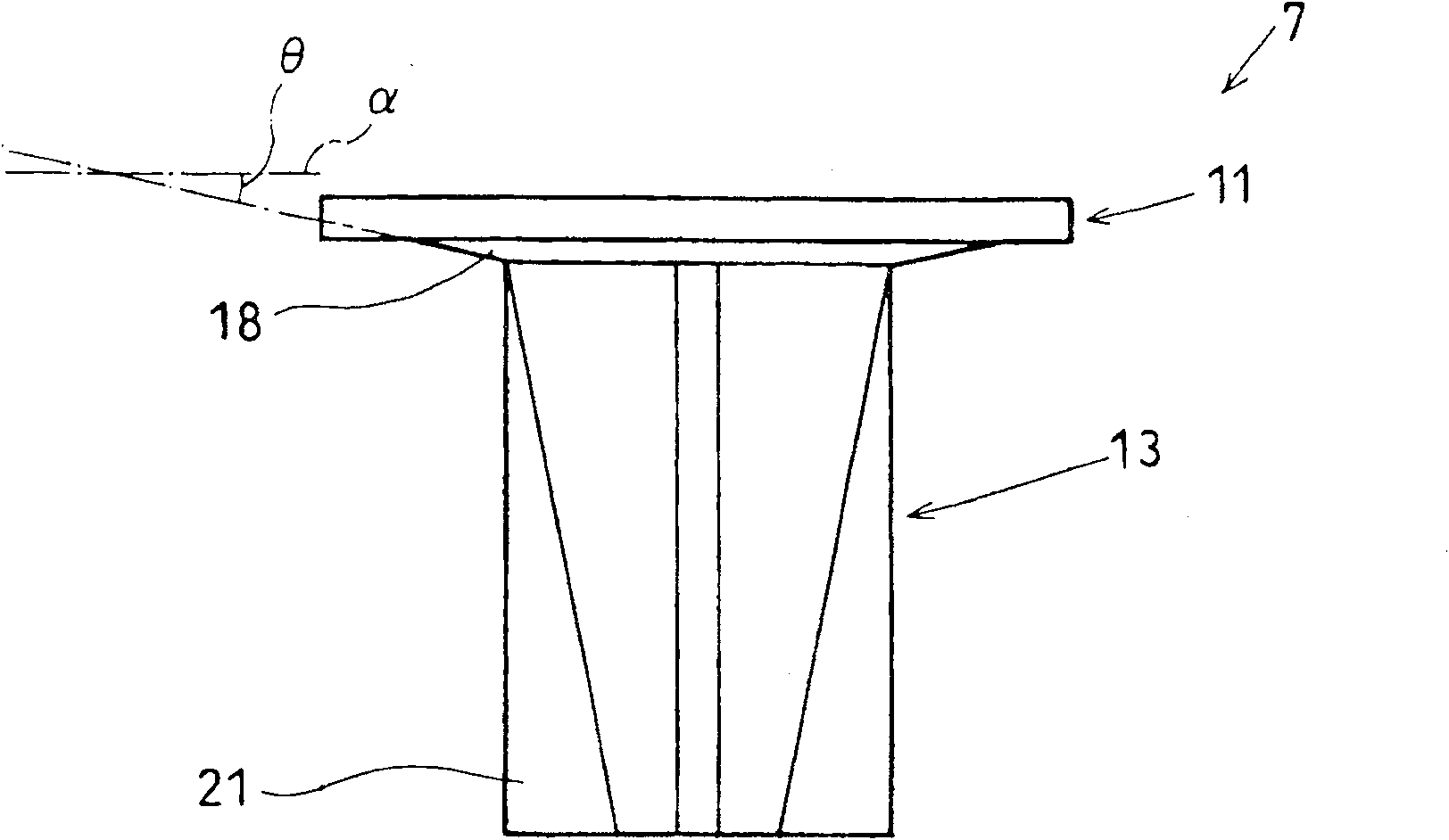

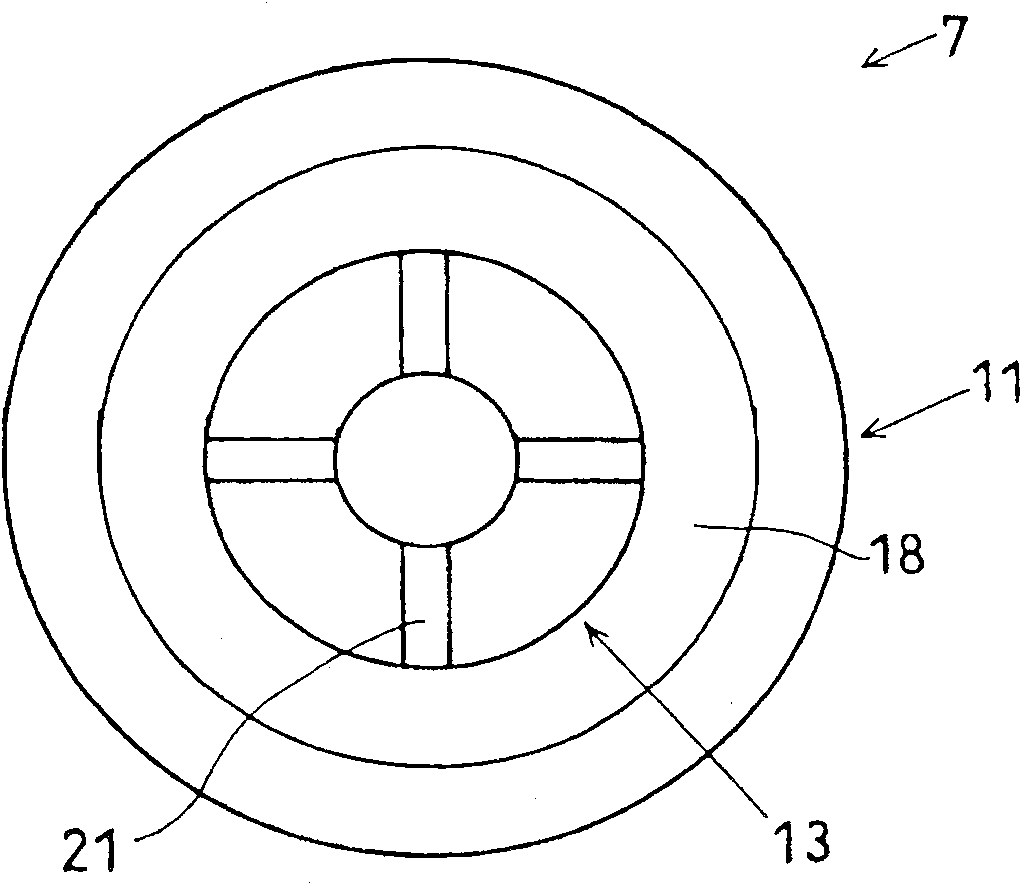

[0013] A flow control valve according to one embodiment of the present invention has an axial element and a valve element, wherein the axial element converts torque applied by a stepping motor into an axial force and is displaced in the axial direction according to the axial force, The valve element is urged by predetermined urging means to contact the axial member, and is axially displaced according to an urging force applied by the urging means and an axial force transmitted from the axial member. The flow control valve operates the opening of the flow passage by moving the axial member in the axial direction to move the valve member.

[0014] The valve element completely closes the opening of the flow passage by seating on the opening edge defining the predetermined opening, and the seating surface of the valve element seated on the opening edge is formed to be inclined with respect to a plane parallel to the opening edge.

[0015] Also, the inclination angle of the seating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com