Quick fixing mechanism of lower roller

A technology of quick installation and rack, applied in the field of quick installation and disassembly mechanism and lower roller quick installation mechanism, which can solve the problems of troublesome disassembly and assembly, difficult positioning of two lower rollers, and high machining accuracy of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

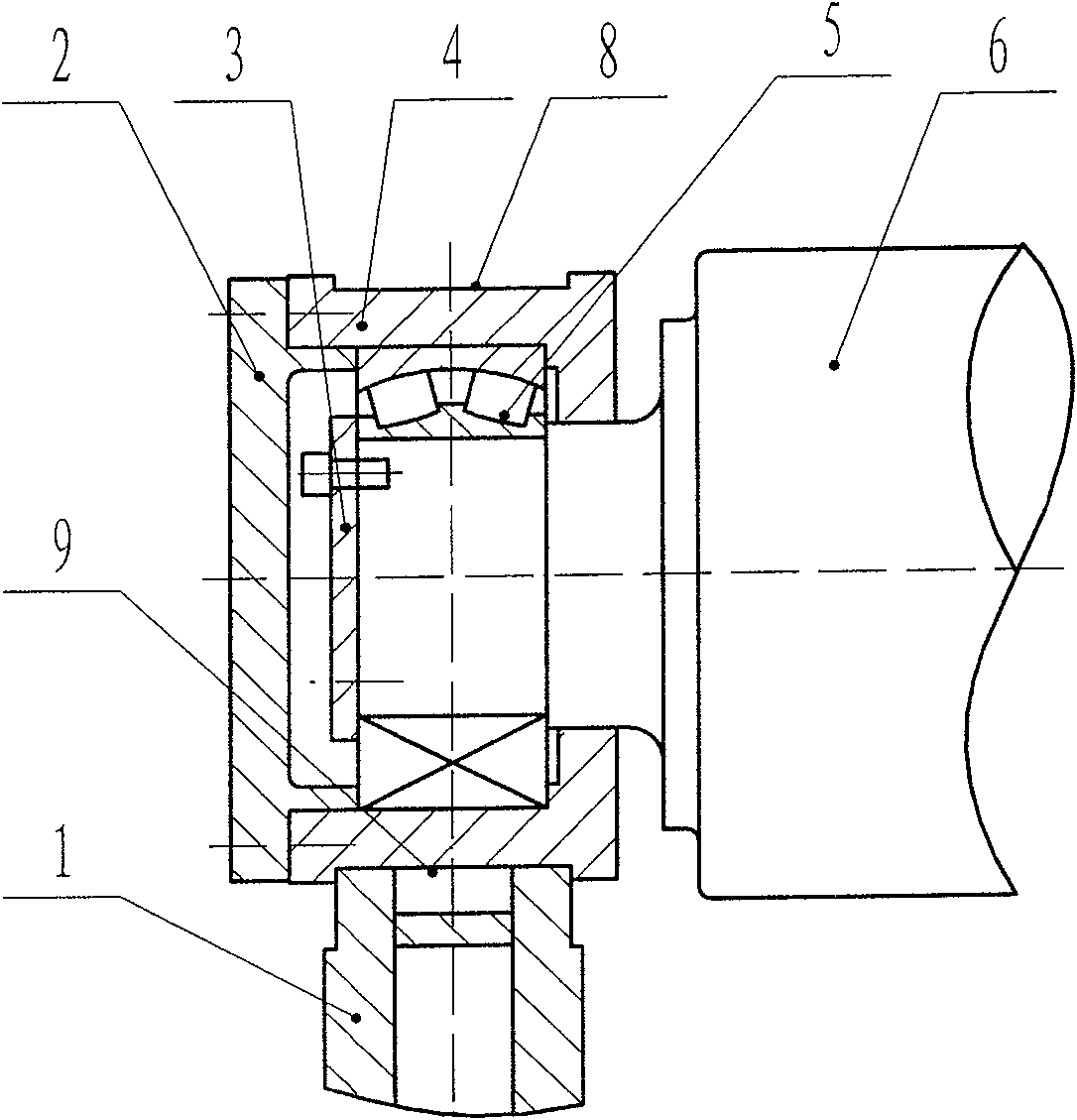

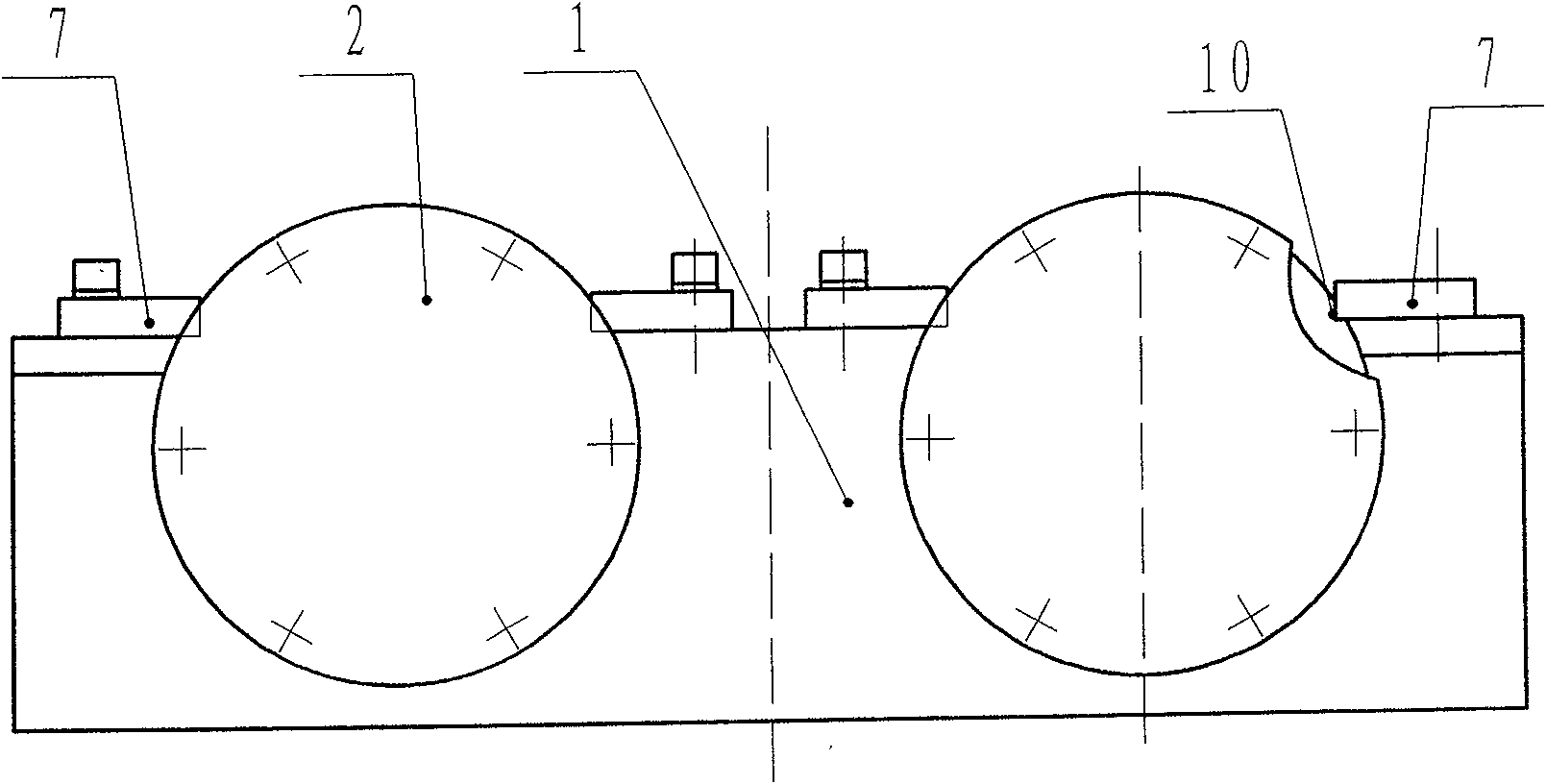

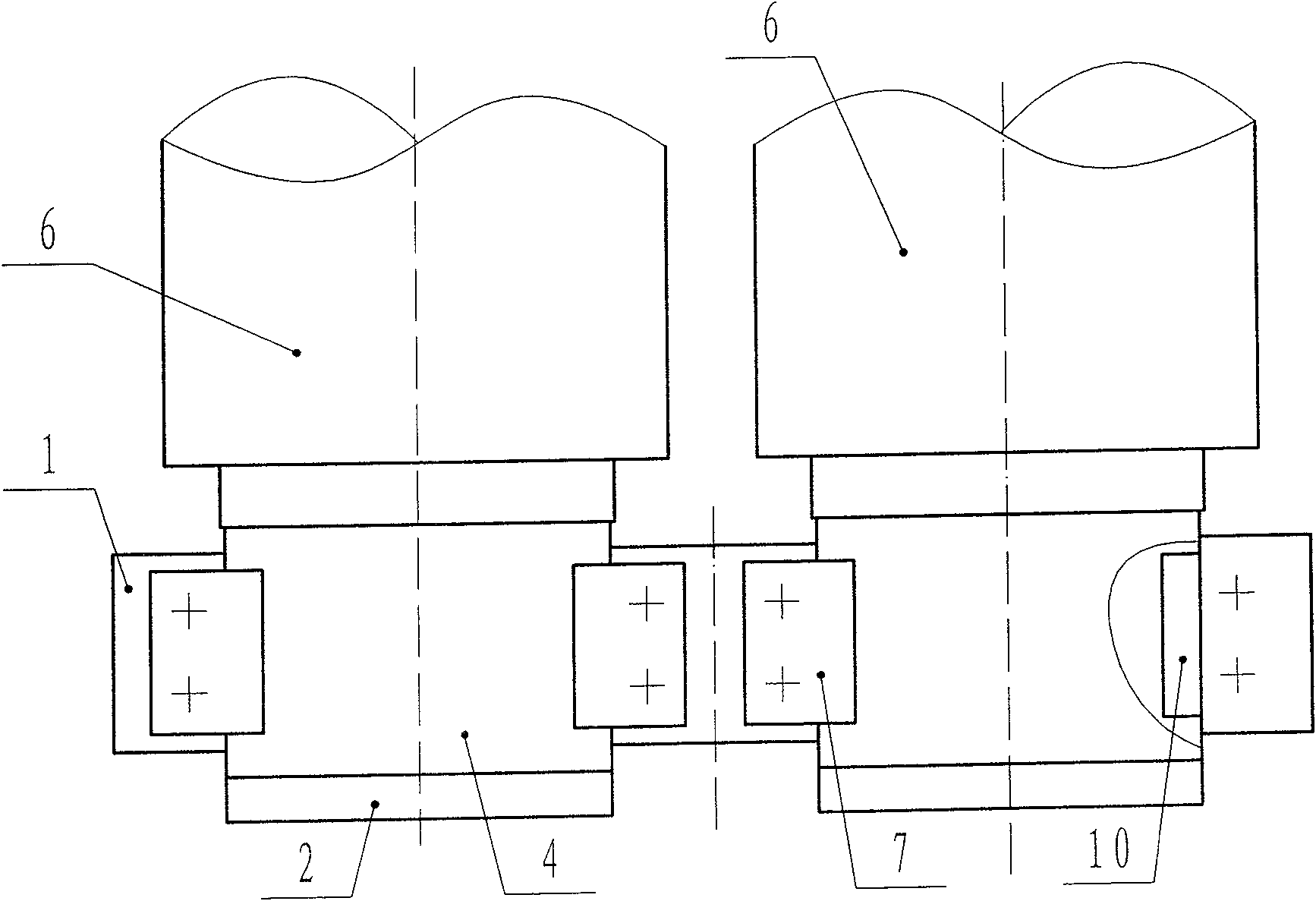

[0015] Such as figure 1 , figure 2 and image 3 Shown: the lower roller quick-installation mechanism, including frame 1, two sets of lower rollers 6, bearings 5, and quick-installation bearing body 4, and a quick-installation bearing body 4 with a U-shaped groove is fixed on the left end of each group of lower rollers 6, The right end of each group of lower rollers 6 is connected with a torsion power device, and the bearing 5 is set on the left shaft head of the lower roller 6, and is located in the U-shaped groove of the quick-installation bearing body 4, and the outer end surface of the quick-installation bearing body 4 is set There is a notch 8, and the quick-loading bearing body 4 is fixed in the corresponding groove 9 of the frame 1 through the notch 8. On the notch 8 of the fast-loading bearing body 4, a positioning step 10 is arranged at the top of the groove 9, and the fast-loading bearing body 4 is fixed by the fixing plate 7 and the positioning step 10 on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com