Roller chain for driving

A technology of roller chains and inner chain links, applied in the direction of transmission chains, etc., can solve the problems of not providing light weight, and achieve the effect of large weight reduction and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

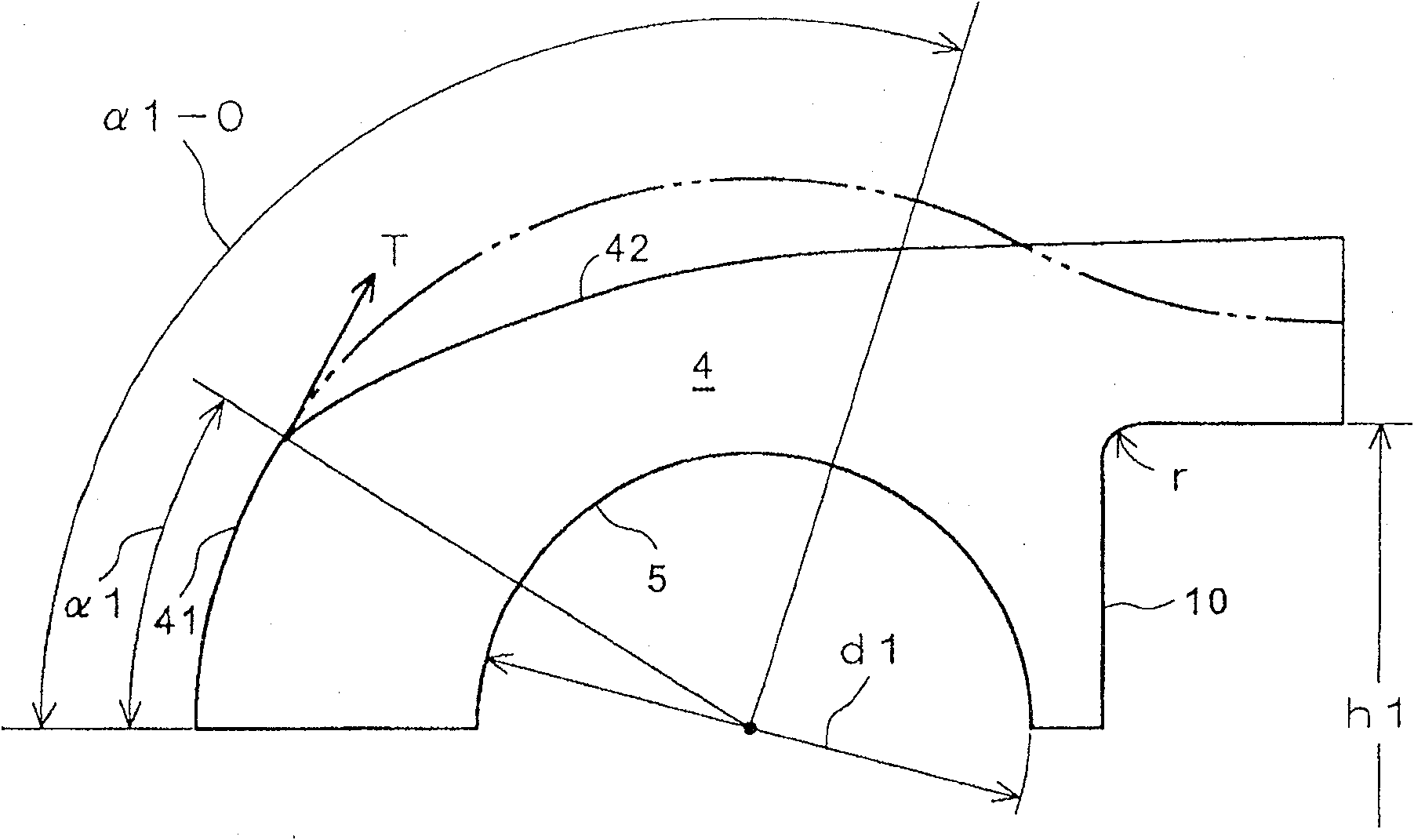

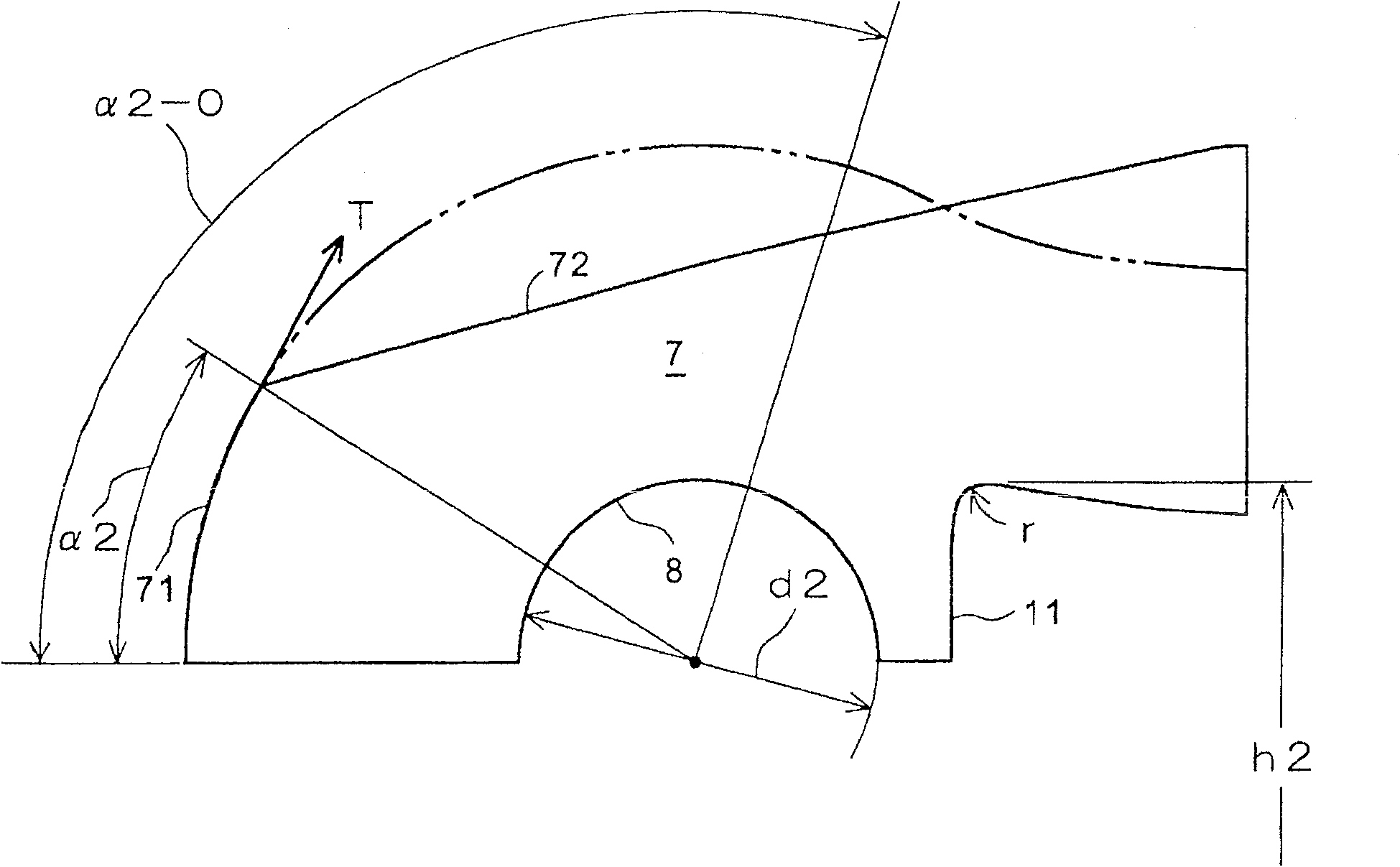

Embodiment Construction

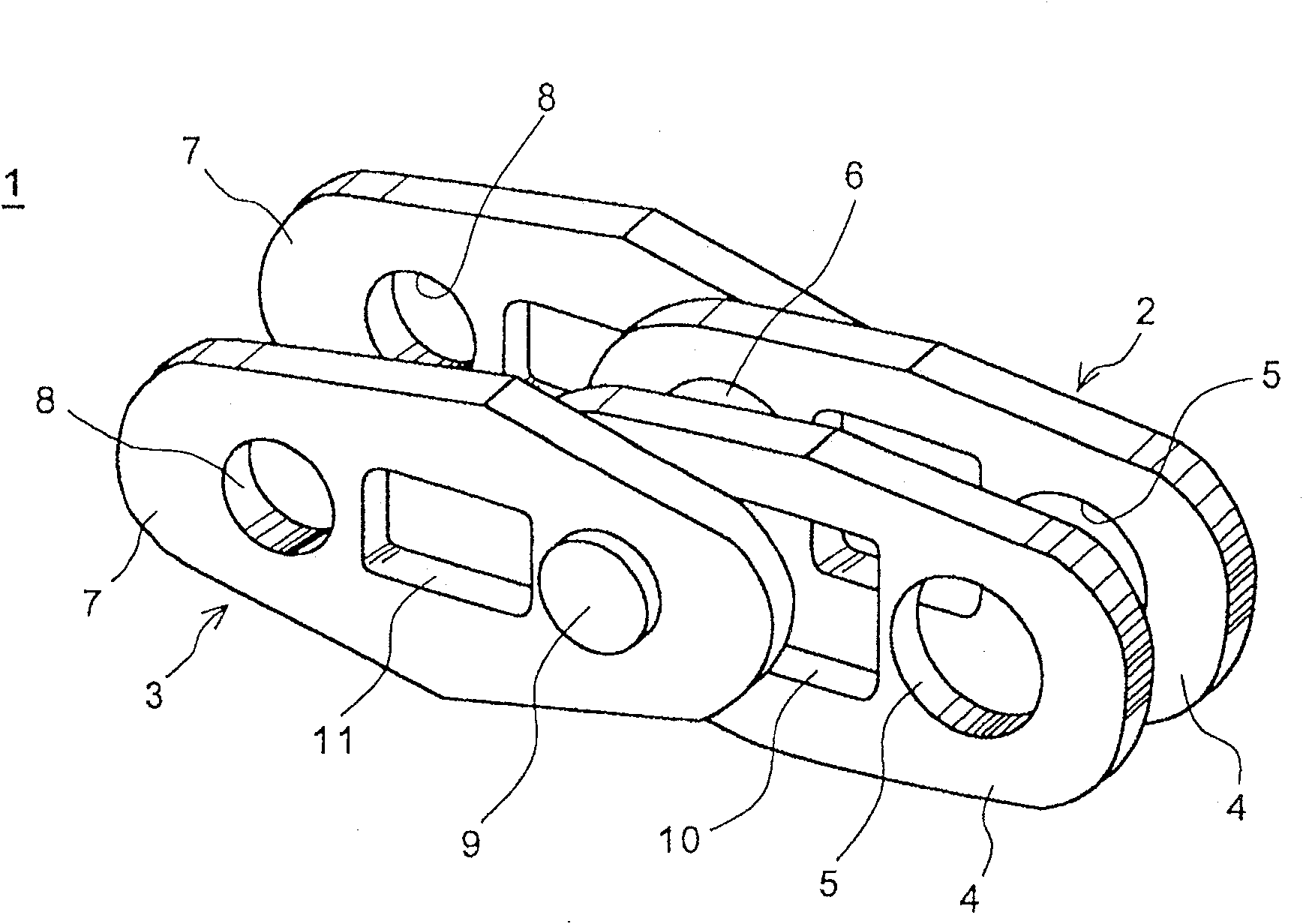

[0031] Hereinafter, one embodiment of the present invention will be described with reference to the drawings. image 3 It is a perspective view of main parts of a driving roller chain according to an embodiment of the present invention, Figure 4 is its top view. This driving roller chain is used, for example, in motorcycles to transmit the output power of an engine to drive wheels. The inner link 2 and the outer link 3 are sequentially connected to form a drive roller chain 1 of a desired length. The inner link 2 is composed of a pair of inner link plates (hereinafter simply referred to as “inner plates”) 4 and a bushing 6 fitted into a bushing hole 5 formed in the inner plates 4 . On the other hand, the outer link 3 is composed of a pair of outer link plates (hereinafter simply referred to as “outer plates”) 7 and coupling pins 9 fitted into pin holes 8 formed in the outer plates 7 .

[0032] In addition to two pairs of bushing holes 5 , the inner plate 4 also has a recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com