Rail vehicle whole tightness test method and system

A rail vehicle and test system technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, can solve the problems that cannot meet the quality requirements, and achieve simple and feasible operation and high detection accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

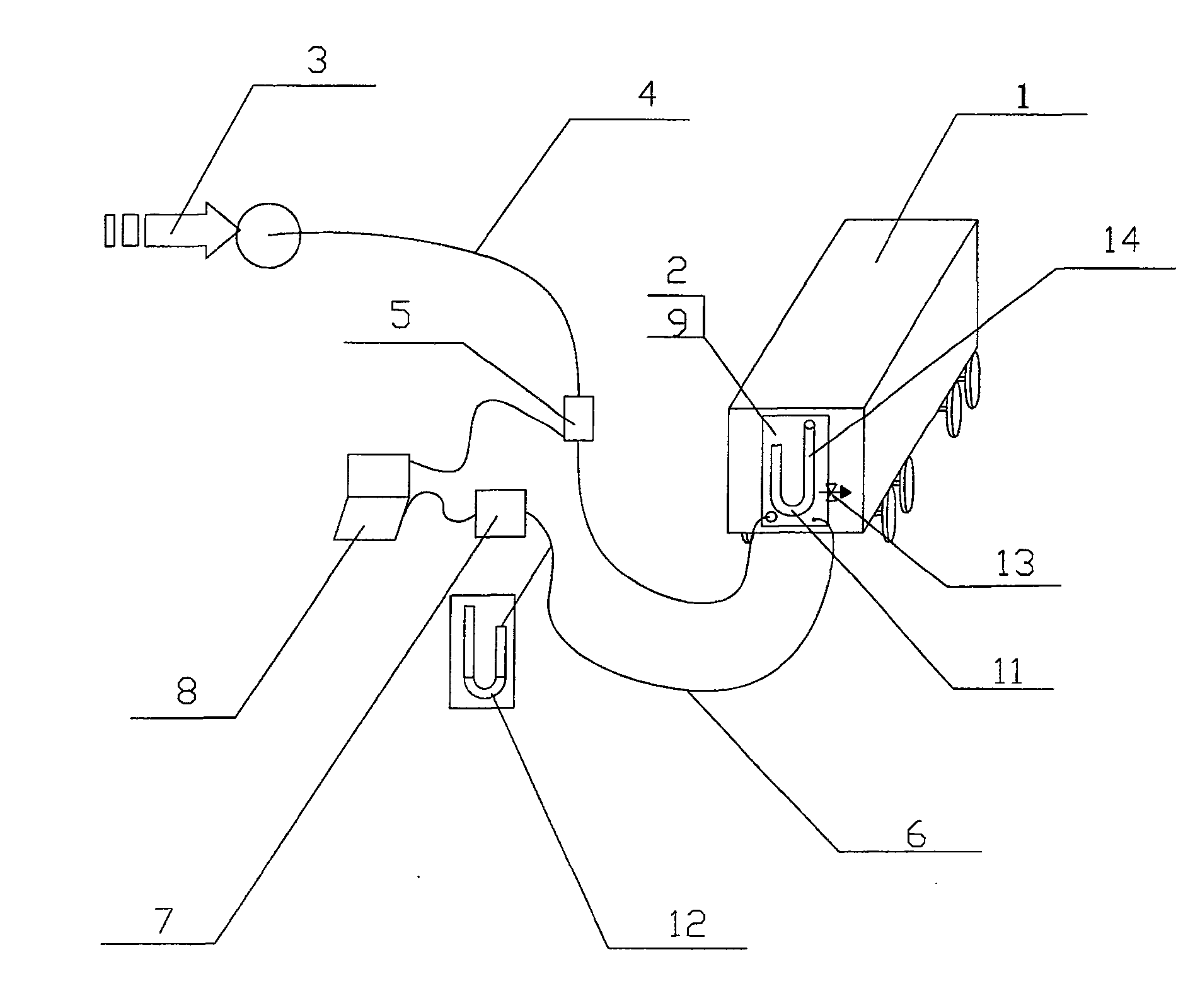

[0021] Such as figure 1 As shown, the airtightness test system for rail vehicles of the present invention includes: a compartment sealing device, an air source 3 , an intake pipe 4 , a solenoid valve 5 , a detection air pipe 6 , a pressure sensor 7 , and a computer console 8 .

[0022] Before carrying out the airtightness test, the entire car compartment 1 under test must be sealed. In addition to closing the windows, the doors 2 at both ends of the compartment 1 must be sealed.

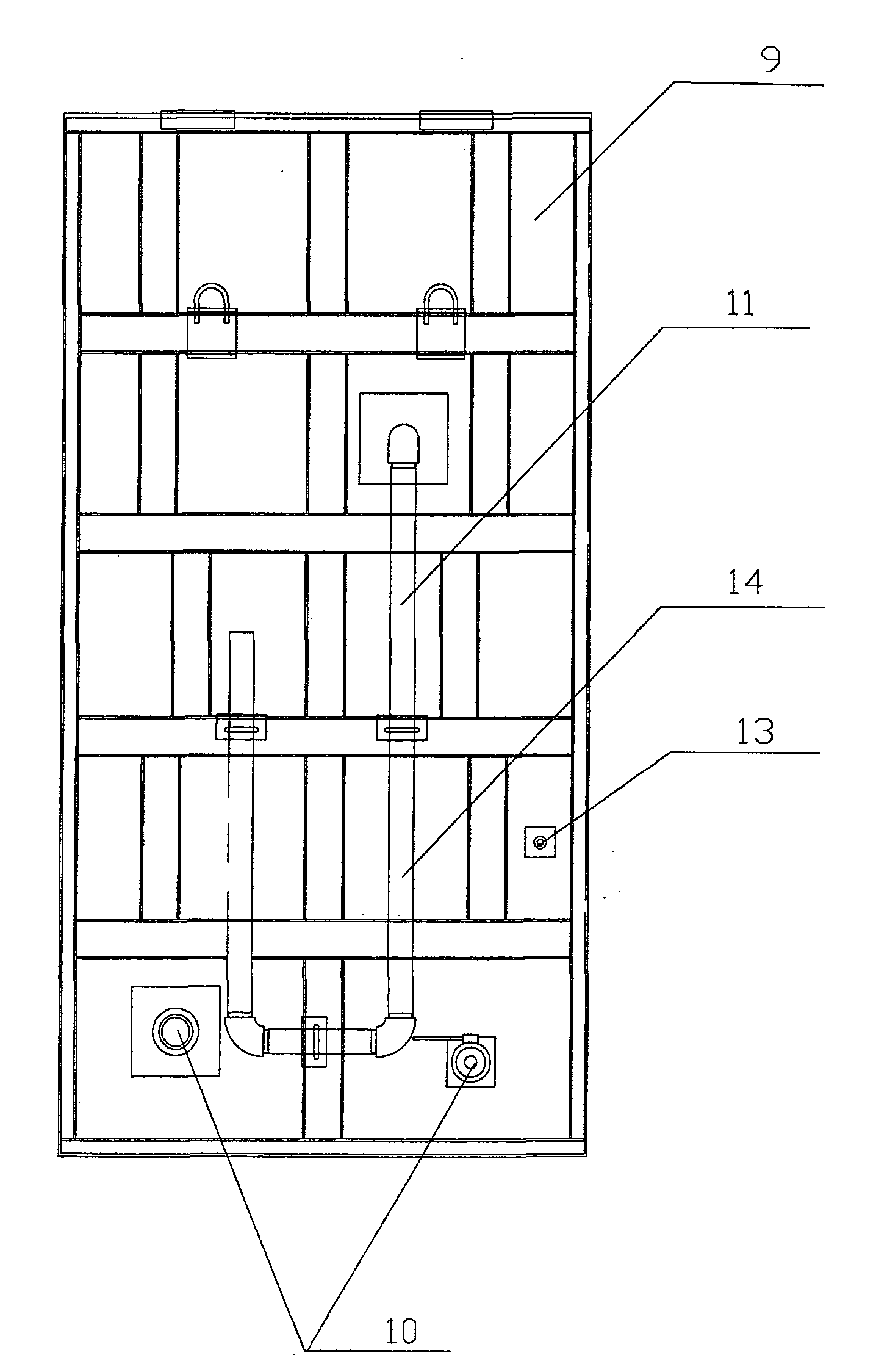

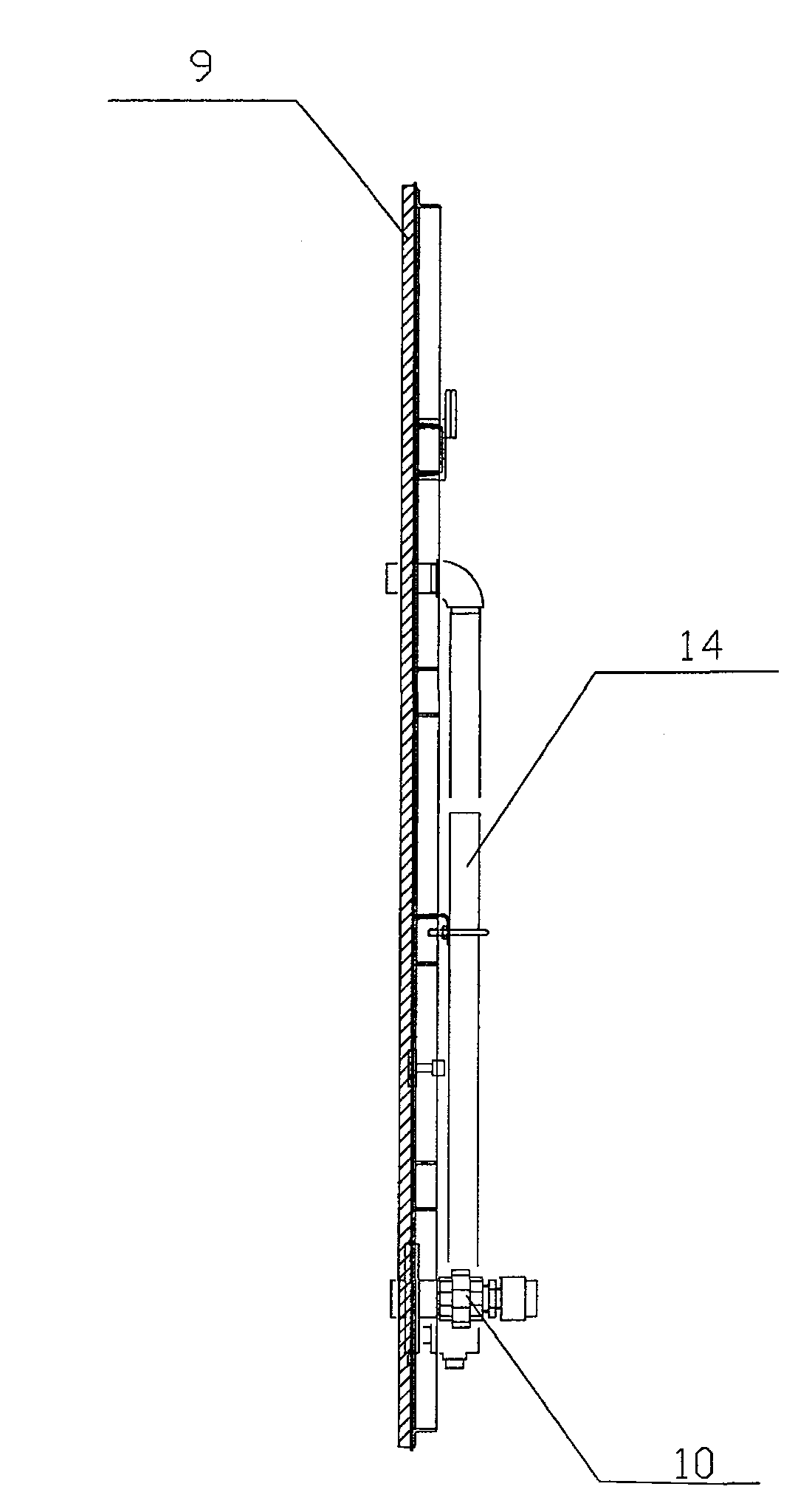

[0023] Car door 2 adopts airtight end door 9 to seal, and airtight end door 9 is a frock door, and it is fixed on the door frame of car door 2, and seals with sealing strip (such as can adopt rubber strip etc.) with car door 2, and uses Tooling connects and fixes the doorframe of car door 2 with airtight end door 9. In order not to damage the doorframe of car door 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com