Tunnel lining segment and preparation method thereof

A technology for lining segments and tunnels, used in tunnel linings, tunnels, shaft linings, etc., can solve the problems of concrete segment bursting, overall structure damage, and high cost, preventing concrete bursting, eliminating test errors, and improving fire resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

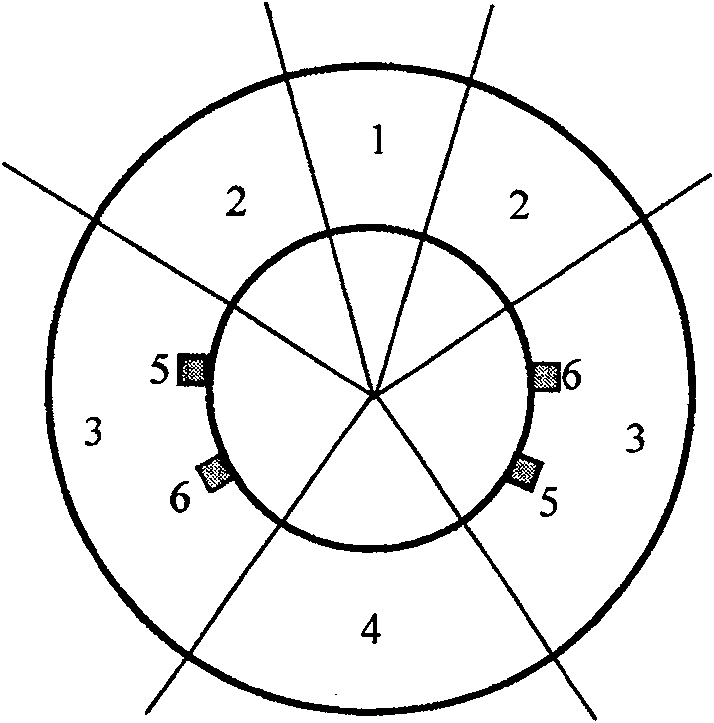

[0042] Embodiment 1 Preparation and calibration of carbon fiber cement-based sensor

[0043] Carbon fiber mortars with carbon fiber volume additions of 0.2%, 0.3% and 0.5% were prepared.

[0044] Carbon fiber mortar preparation method: Pour the weighed chopped carbon fiber (carbon fiber length is 5-10mm) into the stirring device, add water and methyl cellulose and stir evenly, then slowly add silica fume, cement, yellow sand and defoamer Finally, slowly add high-efficiency superplasticizer to adjust the fluidity, and stir for 3 minutes. Then into the mold vibration molding.

[0045] The ratio (mass ratio) of the cement-based material is: cement: silica fume: yellow sand: water: methylcellulose: defoamer: superplasticizer = 1:0.15:1:0.4:0.0006:0.001:0.005. The defoamer is an industrial aliphatic hydrocarbon surfactant, and the high-efficiency water reducer is a polycarboxylic acid superplasticizer.

[0046] The size of the sensor is 5cm×5cm×5cm, and the test strength level i...

Embodiment 2

[0050] Example 2 Preparation of Tunnel Lining Segments

[0051] Select polypropylene fibers that meet the following conditions:

[0052] The length is 12-18mm, the average diameter is 60 microns, the elongation is greater than 15%, the tensile strength is greater than 500MPa, the elastic modulus is 3.0-5.0GPa, and the density is 0.91g / cm 3 , the melting point is lower than 170°C.

[0053] The volume content of polypropylene fiber is selected as 0.05%, 0.1%, and 0.2%, respectively.

[0054] Other raw materials for concrete include ordinary Portland cement with a strength grade of 42.5; finely ground slag of S95 and above; medium sand; and limestone with a maximum particle size of less than 25mm. High-efficiency water-reducing agent with a water-reducing rate higher than 30%. Calculate the concrete mix ratio according to the strength design requirements, then weigh the raw materials according to the calculation requirements, add water and stir them evenly, and then pour them ...

Embodiment 3

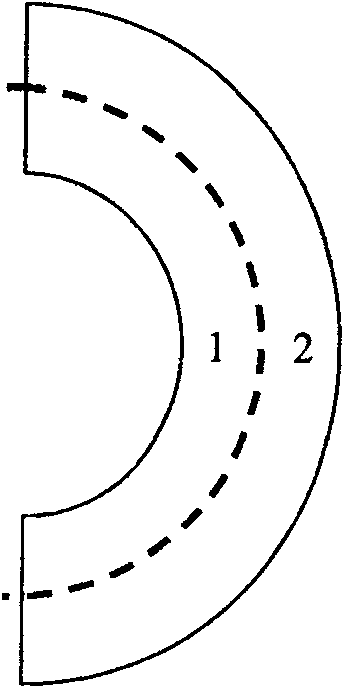

[0062] Example 3 Preparation of Tunnel Lining Segments

[0063] The preparation steps are the same as in Example 2, wherein the pouring range of polypropylene fiber concrete is the thickness range of 5 cm inside, and the other thickness ranges are poured with ordinary concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com