Hanging bracket for integral hoisting of ship superstructure and hoisting process

A superstructure and overall hoisting technology, applied in ship construction, ship parts, transportation and packaging, etc., can solve the problems of reduced rigidity, large size, large weight, small scale, etc., and achieve good rigidity, light weight, and convenient connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

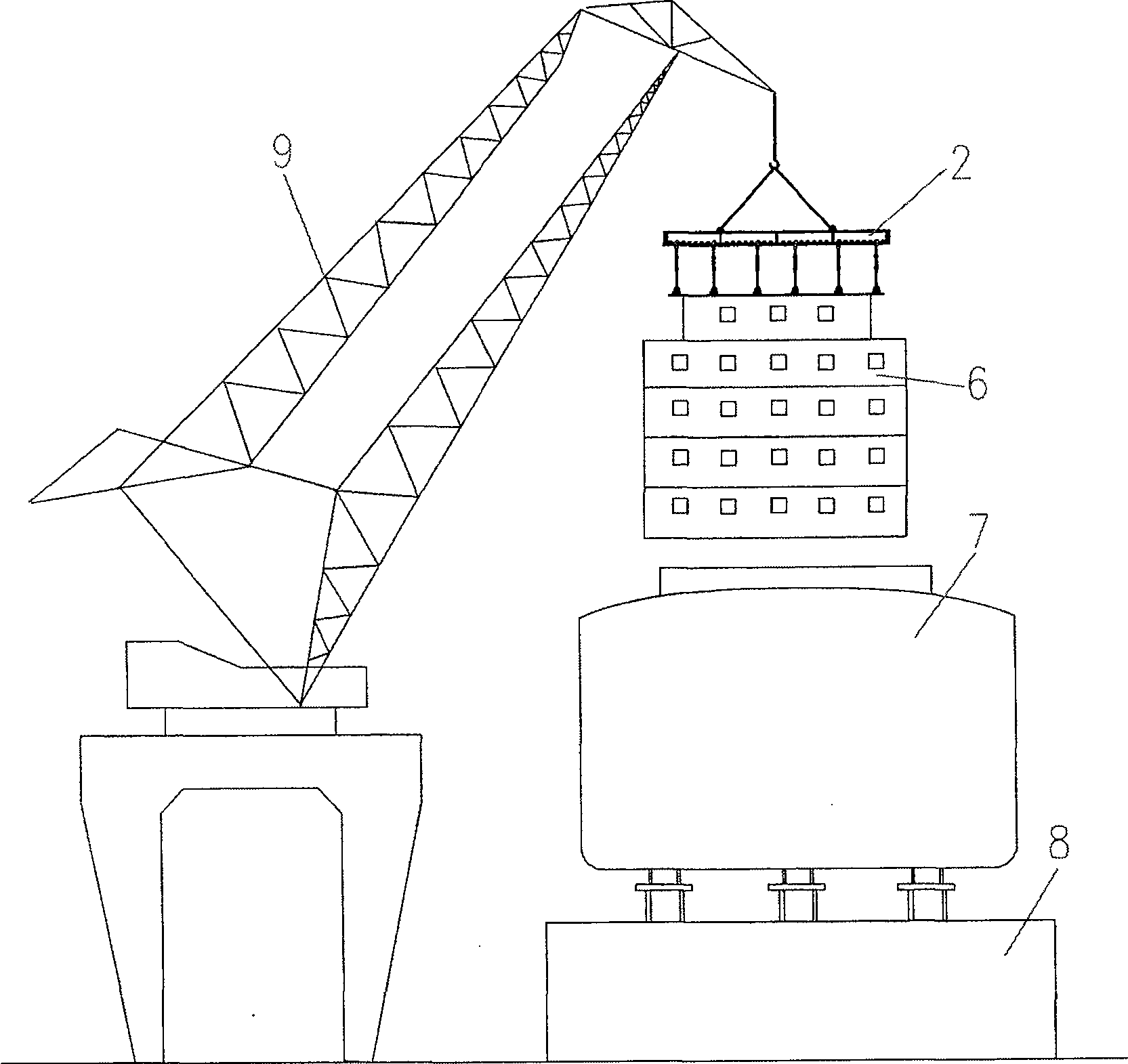

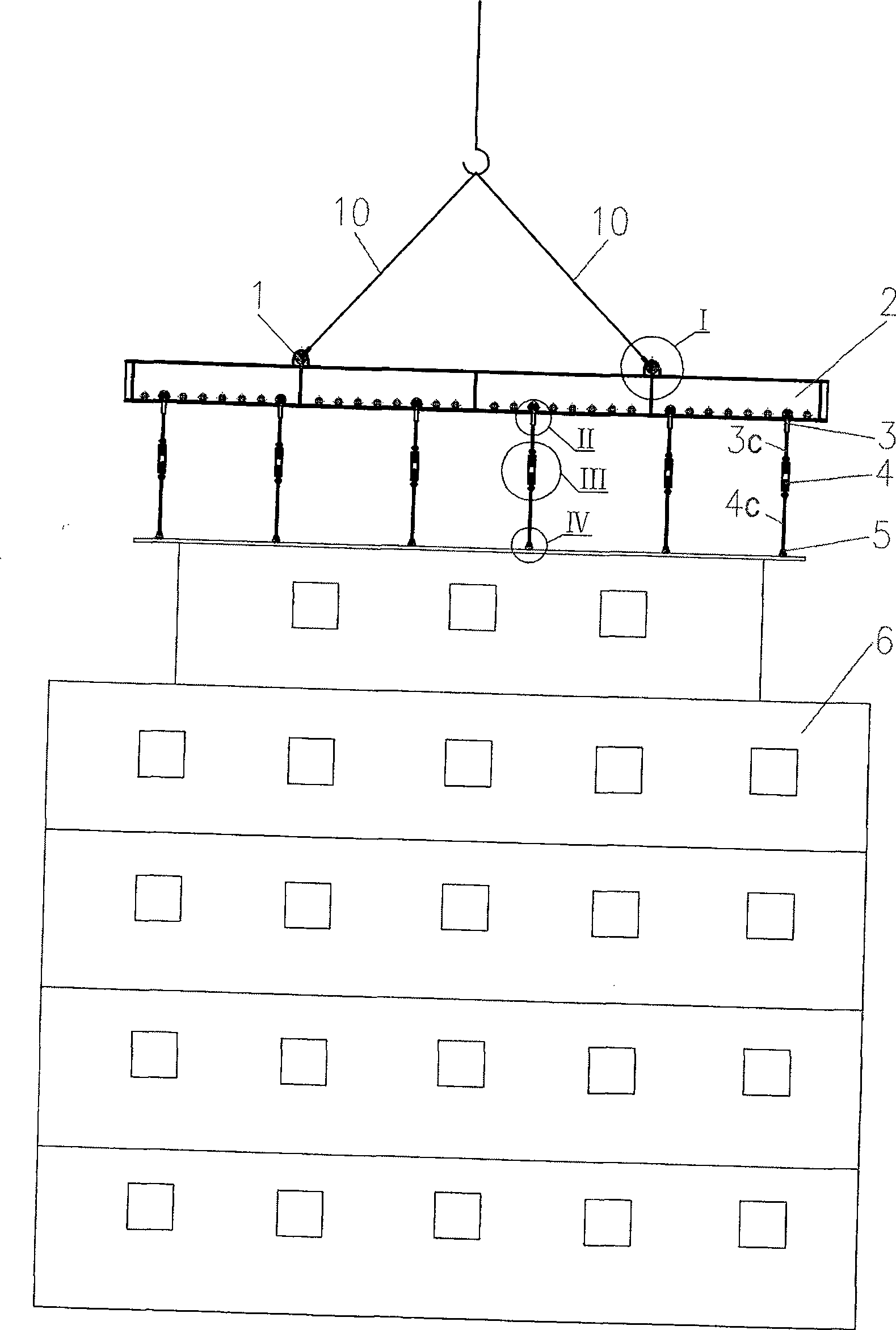

[0030] figure 1 It shows that the crane 9 hoists the ship superstructure 6 to the ship main body 7 on the berth 8 through the hanger 2.

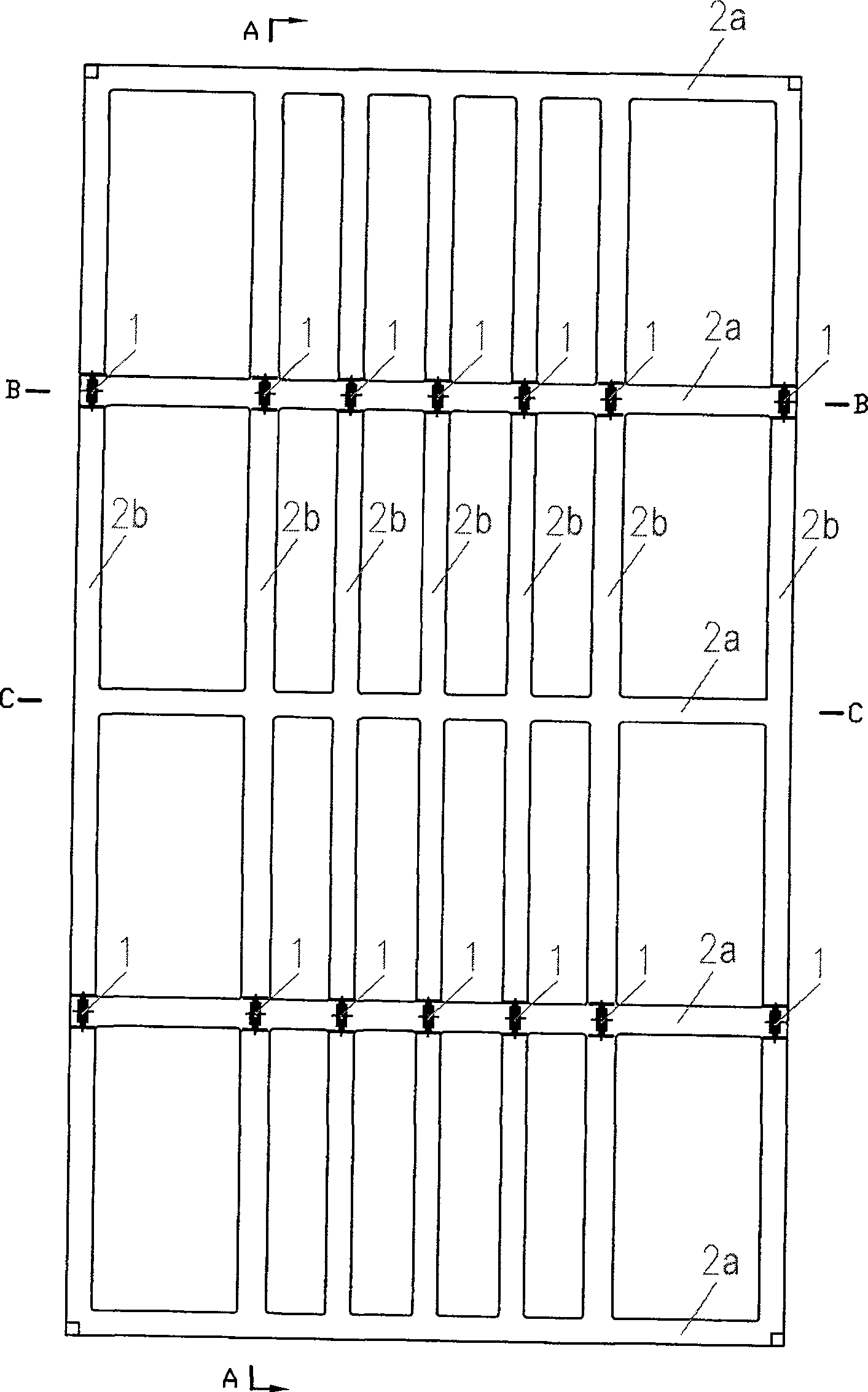

[0031] image 3 As shown, the hanger 2 is a frame structure composed of 4 transverse members 2a and 7 longitudinal members 2b. Such as Figure 6 , Figure 7 , Figure 8 As shown, the transverse member 2a is an I-shaped cross-section beam welded together by a first upper panel 2a1, a first vertical panel 2a2 and a first lower panel 2a4, and is provided at the lower part of the first vertical panel 2a2 near the first lower panel 2a4. There is a row of 16 first lifting holes 2a5, and the first composite board 2a3 is welded on both sides of the first lifting holes 2a5. Such as Figure 4 , Figure 5 As shown, the longitudinal member 2b is an I-shaped cross-section beam welded together by the second upper panel 2b1, the second vertical plate 2b2 and the second lower panel 2b4, and is arranged at the lower part of the second vertical plate 2b2 near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com