Connector and connector device

A connector and mating connector technology, which is applied to the parts of the connection device, the device to prevent wrong connection, the connection and other directions to achieve the effect of reducing the operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

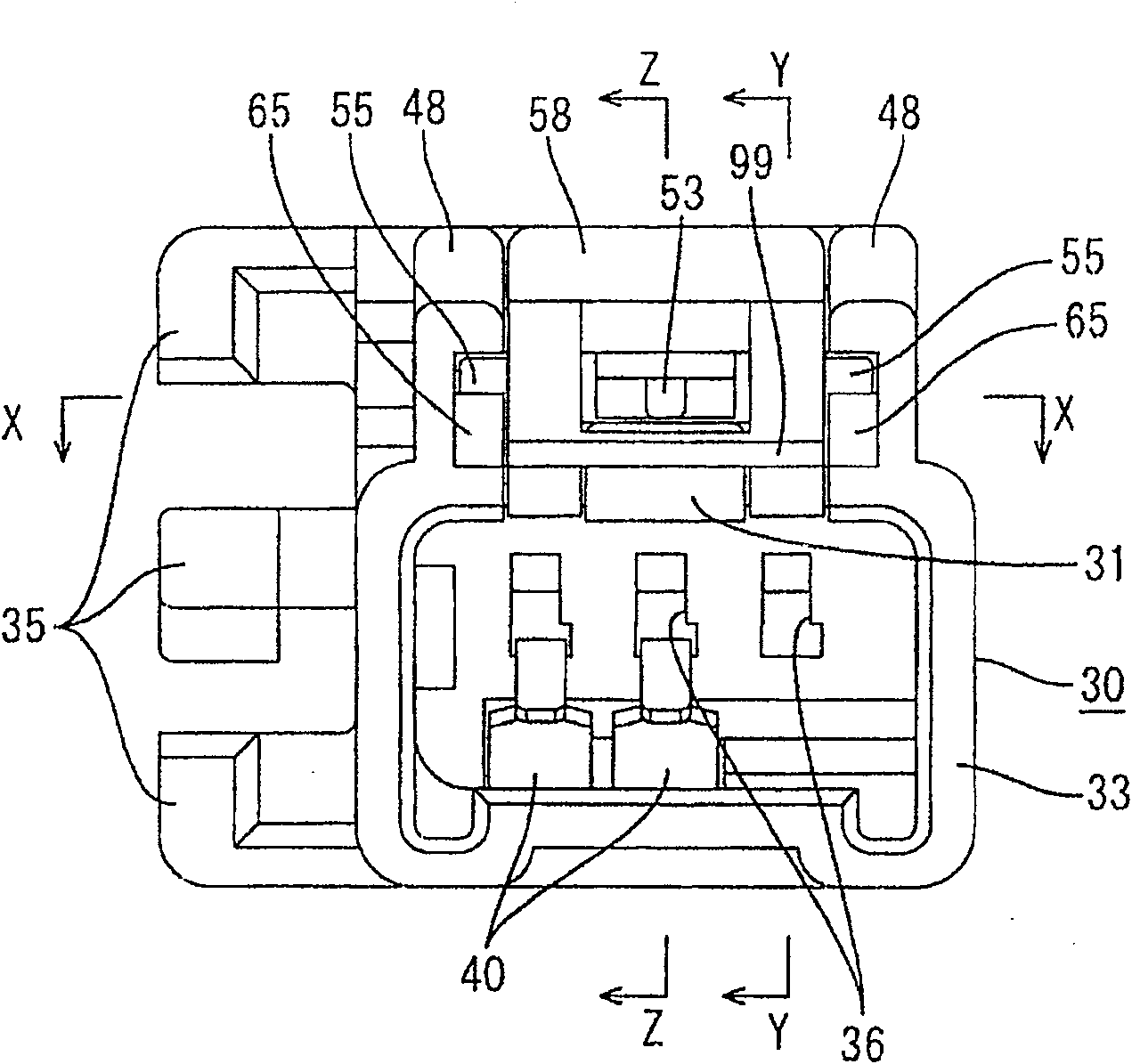

[0072] Refer to attached Figures 1 to 18 A first embodiment of the present invention will be described. In this embodiment, the slider (as the preferred movable member) 50 and at least one compression coil spring (corresponding to the preferred biasing means) will be at least partially fitted to the male connector housing (hereinafter, simply referred to as "male housing 30"), the male housing can be connected to a female connector housing (hereinafter, only referred to as "female housing 10"). In the following description, the sides where the male housing 30 and the female housing 10 are connected are referred to as fronts in the forward and rearward directions.

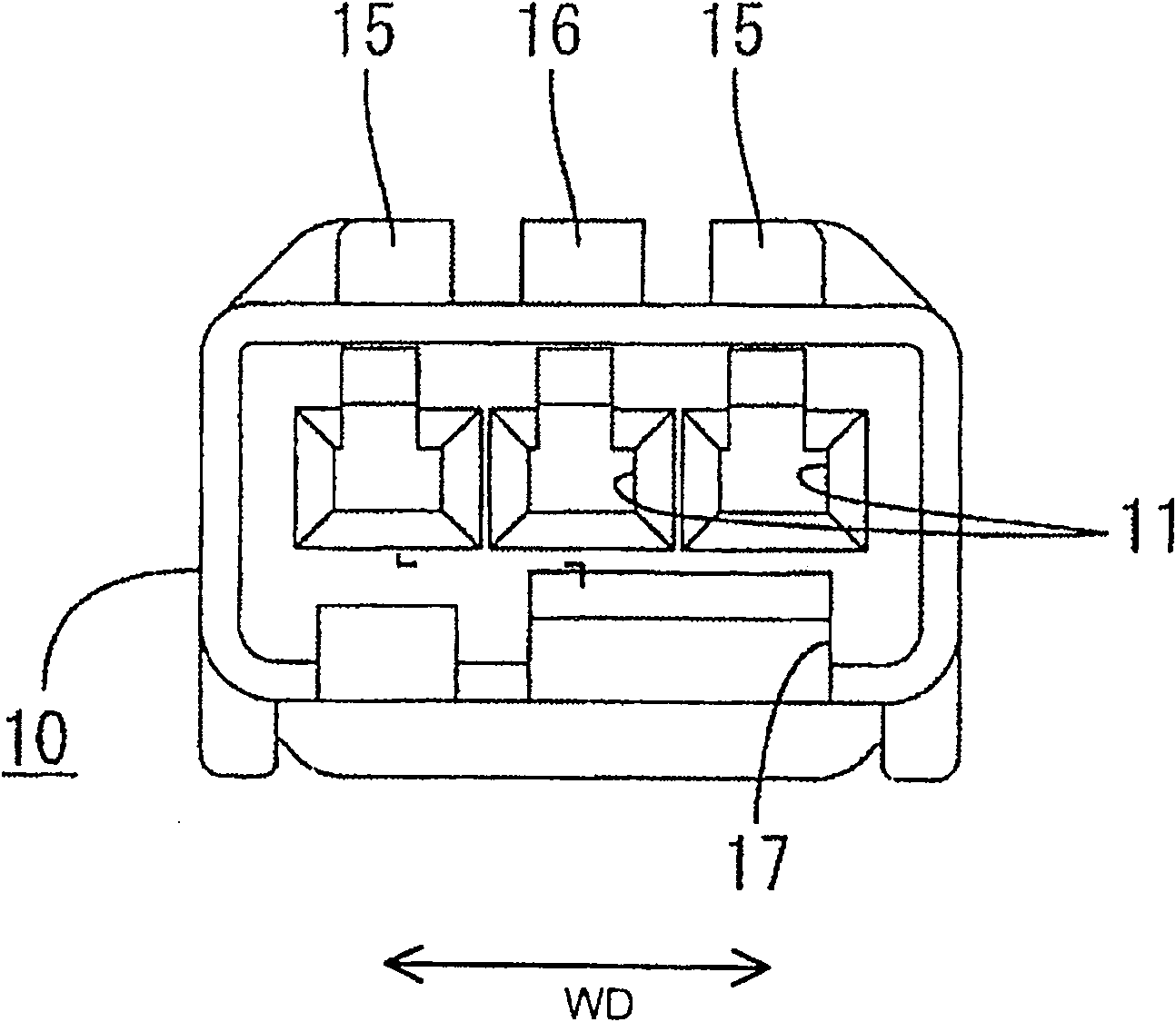

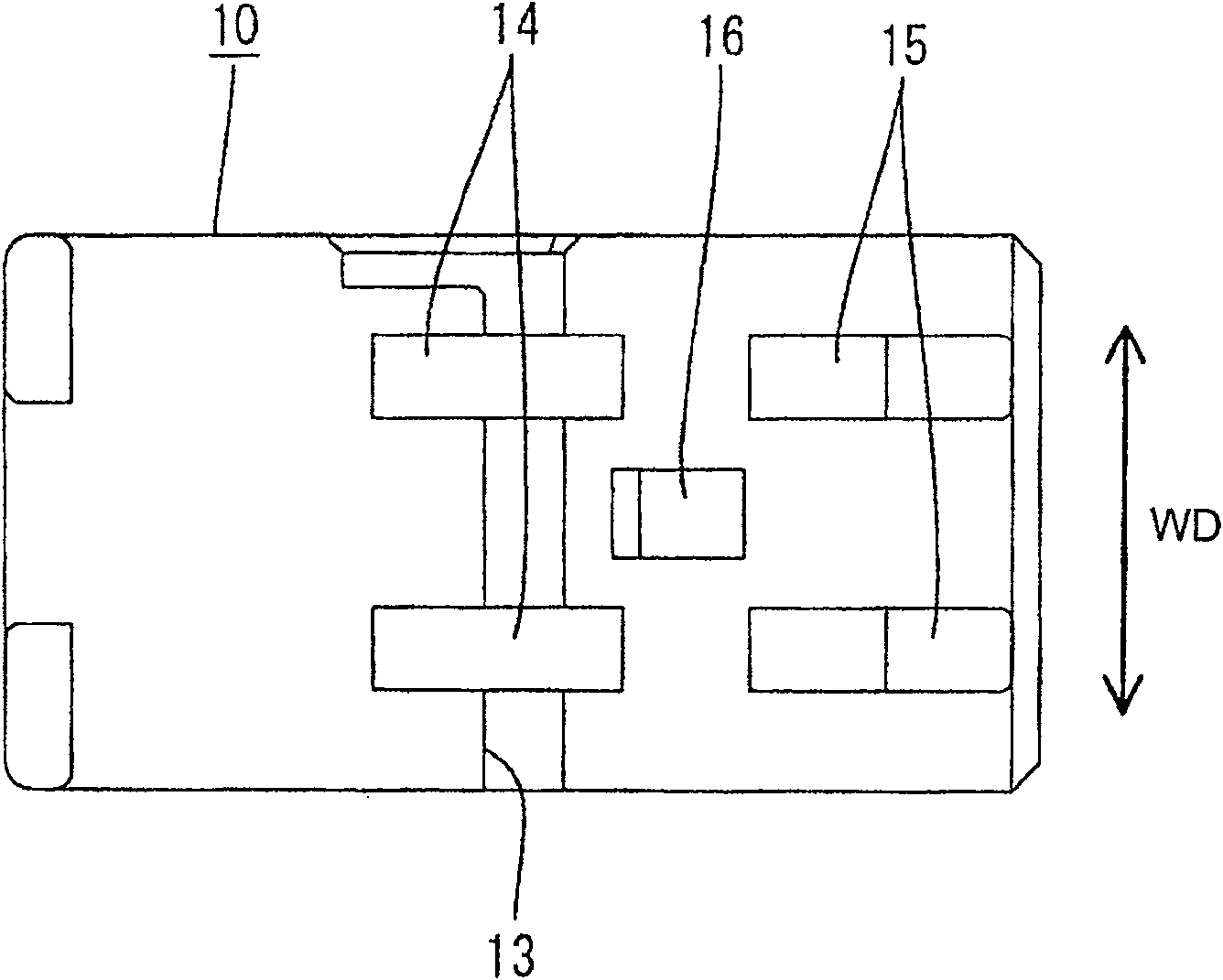

[0073] The female housing 10 is made of, for example, a synthetic resin material, and is preferably substantially in the form of a monolithic block, and one or more such as three cavities 11 are preferably arranged substantially side by side in one or more of the female housing 10 One or more corresponding female...

no. 2 example

[0106] attached Figure 19 A second embodiment of the present law is shown. This second embodiment differs from the first embodiment in the structure of the lock arm 31 and the arm pressing portion 52, but is similar or substantially the same in other structures.

[0107] The locking arm 31 of the second embodiment includes an arm main body 45 in the form of a long and narrow rod, and a substantially block-shaped locking portion 39 is continuous with the leading end of this arm main body 45 . The width of locking portion 39 is preferably greater than the width of arm main body 45, and rear surface 39A of locking portion 39 is a stepped surface, and this stepped surface is at an angle not equal to 0° or 180°, preferably substantially opposite to arm main body 45. The side surfaces are at right angles. On the other hand, an arm exit portion 57 for at least partially accommodating the lock arm 31 is formed at the guide side of the arm pressing portion 52 so as to have openings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com