Cold pad-batch dyeing method for textile fabric

A cold pad-batch dyeing and textile technology, which is applied in the processing of textile materials, dyeing methods, textiles and papermaking, etc. It can solve the problems of low affinity of reactive dyes to cotton fibers, increased washing difficulty, sewage treatment capacity, and dyeing rate Insufficient and other problems, to achieve good diffusion and level dyeing performance, low infrastructure investment costs, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Ingredients prescription

[0045] Dye liquid: reactive dye 2g / l

[0046] Penetrant 3g / l

[0047] Defoamer

[0048] The dye solution and alkali agent (4:1) are mixed evenly through the buffer cylinder with a proportional metering pump and enter the rolling groove;

[0049] (2) Pad-rolling conditions: 7 liters of rolling bath liquid, one padding and one rolling at room temperature, the rolling margin is about 65%, and the uniform rolling mill is controlled between 1-1.3kg according to the variety;

[0050] (3) Vehicle speed: general varieties are above 60m / min, and those with more liquid absorption are about 30-40m / min;

[0051] (4) The maximum roll diameter is 1.4m. In order to prevent head prints, the entire shaft should be tightly wrapped;

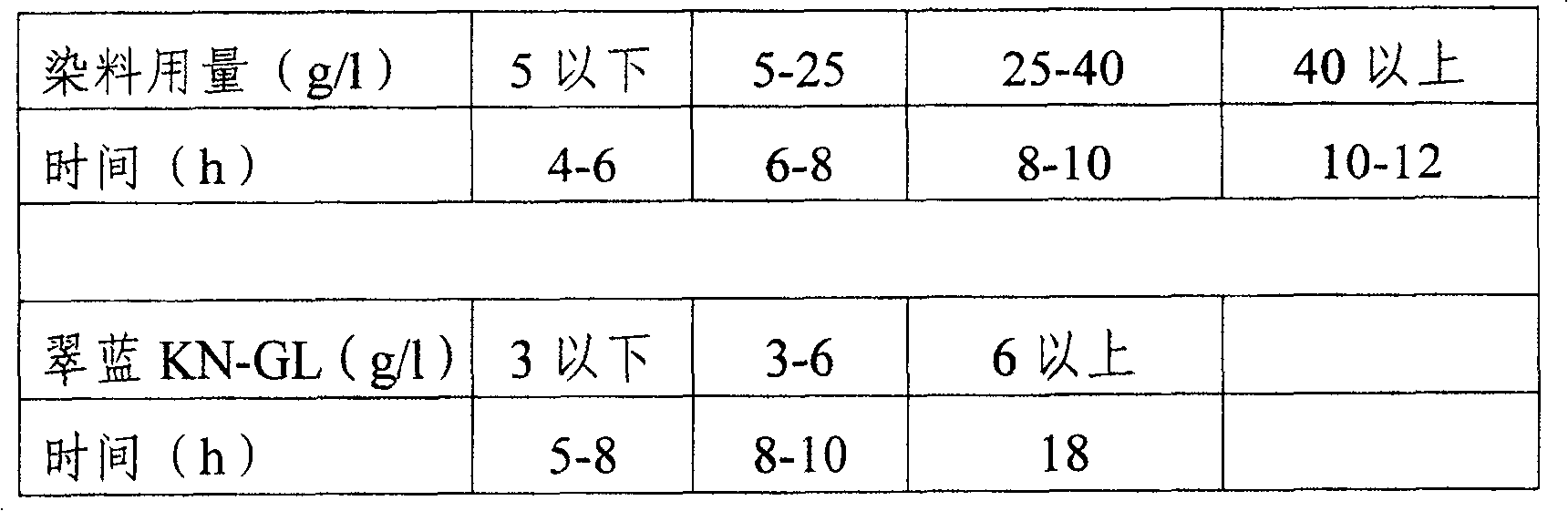

[0052] (5) Rotating and stacking time depends on dye and dosage

[0053]

[0054] 2. Examples of reactive dye cold pad-batch dyeing process

[0055] Dyestuff: X g / l

[0056] Alkali agent: X-type dye soda ash 10-30g / ...

Embodiment 2

[0076] A cold pad-batch dyeing method for textile fabrics, the method includes three stages of immersion, stacking and washing;

[0077] The soaking stage includes the pre-treatment of cold pad stacking, semi-finished products and dyeing padding steps:

[0078] The stacking stage includes rolling and stacking steps;

[0079] The washing stage includes washing, soaping, rewashing and drying steps.

[0080] The pre-treatment of the cold-rolling pile includes the steps of padding with padding working fluid, coiling, stacking, alkali-distilled water washing and drying. The alkali-distilled water washing includes steaming (100° C., 2 to 4 minutes), hot water washing and cold water washing steps.

[0081] When using (destroying) the scouring and bleaching cold stacking method (over 20h at room temperature), the composition ratio (g / l) of the padding working fluid pre-treated by the cold rolling stack is: NaOH: 40; H 2 O 2 : 20; water glass: 3; chelating dispersant: 6 and scouring agent:...

Embodiment 3

[0085] A cold pad-batch dyeing method for textile fabrics, the method includes three stages of immersion, stacking and washing;

[0086] The soaking stage includes the pre-treatment of cold pad stacking, semi-finished products and dyeing padding steps:

[0087] The stacking stage includes rolling and stacking steps;

[0088] The washing stage includes washing, soaping, rewashing and drying steps.

[0089] The pre-treatment of the cold-rolling pile includes the steps of padding with padding working fluid, coiling, stacking, alkali-distilled water washing and drying. The alkali-distilled water washing includes steaming (100° C., 2 to 4 minutes), hot water washing and cold water washing steps.

[0090] When using (destroying) the scouring and bleaching cold stacking method (over 20h at room temperature), the composition ratio (g / l) of the padding working fluid pre-treated by the cold rolling stack is: NaOH: 50; H 2 O 2 : 15; water glass: 5; chelating dispersant: 5 and scouring agent:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gross effect | aaaaa | aaaaa |

| gross effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com