Truss type spud leg single slice lifting slings

A truss-type and pile-leg technology is applied in the field of truss-type pile-leg single-piece spreaders, which can solve the problem that the lifting eye plate cannot be welded on the pile-leg single piece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

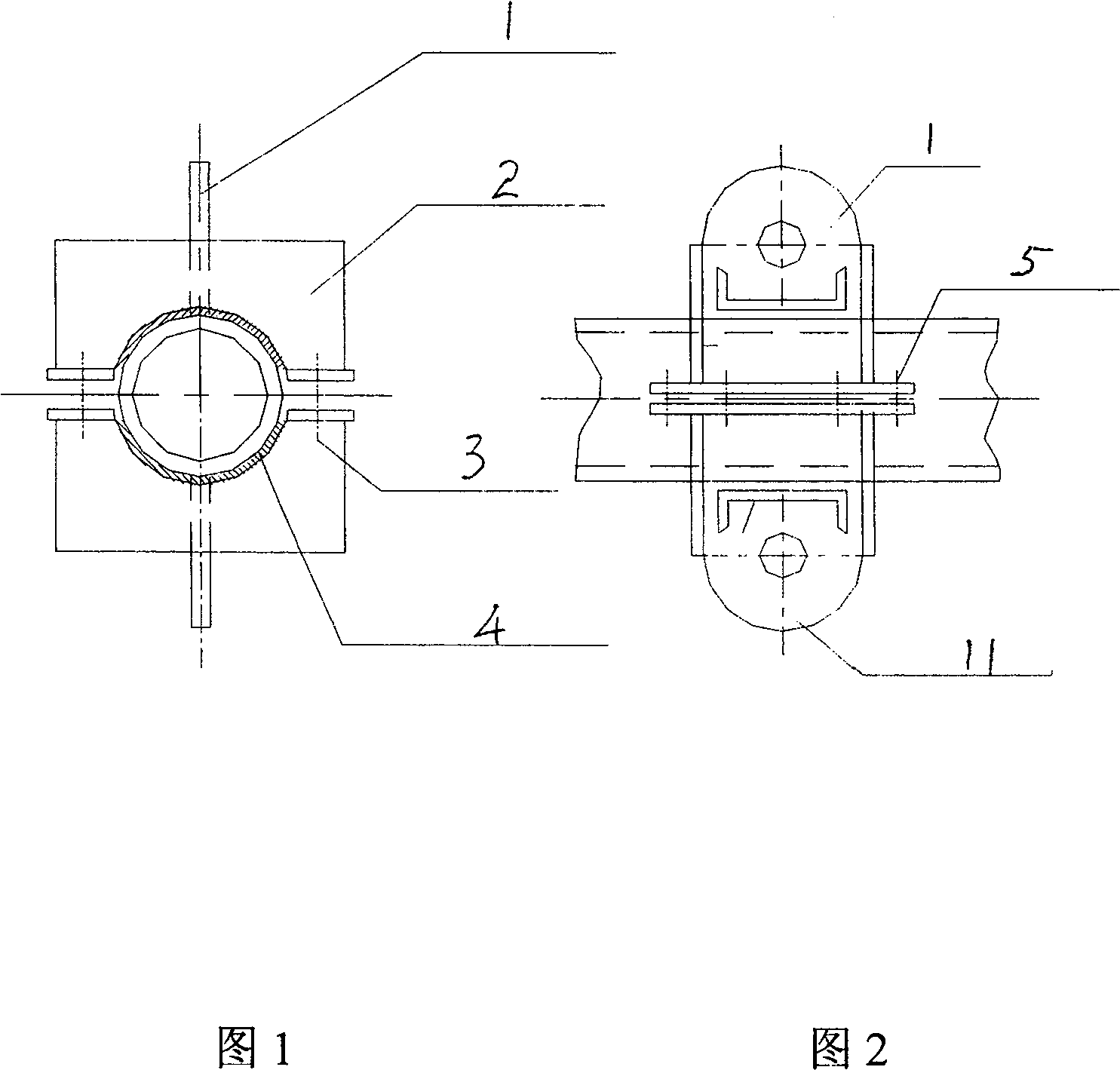

[0006] A self-elevating drilling platform truss type pile leg monolithic spreader of the present invention, the key to the successful construction of the platform is the construction of the pile legs. The shape of the pile legs is a triangular truss type, and each corner is provided with a main chord tube with a rack, which is connected with a structural tube to form a triangular truss. Each pile leg is divided into three single pieces for pre-assembly. After the assembly of each single-piece pre-assembly section is completed, it needs to be transferred to the sub-assembly stand under the 300-ton tank crane for large assembly. The monolithic pre-assembled section structure consists of a 25-meter-long main chord and three horizontal pipes, with a weight of about 50 tons. The center of gravity is obviously biased to one side, which brings difficulties to the arrangement of lifting points; The sections are located at three different angles, and the assembly precision is high. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com