Stabilizing mechanism for hoisting shaft cage and stabilizing device

A technology of cage lifting and tank stabilization, which is applied to lifting equipment, transportation and packaging in mines, can solve problems such as large up and down movement, and achieve the effects of reducing dynamic load, simple structure, and convenient installation and debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

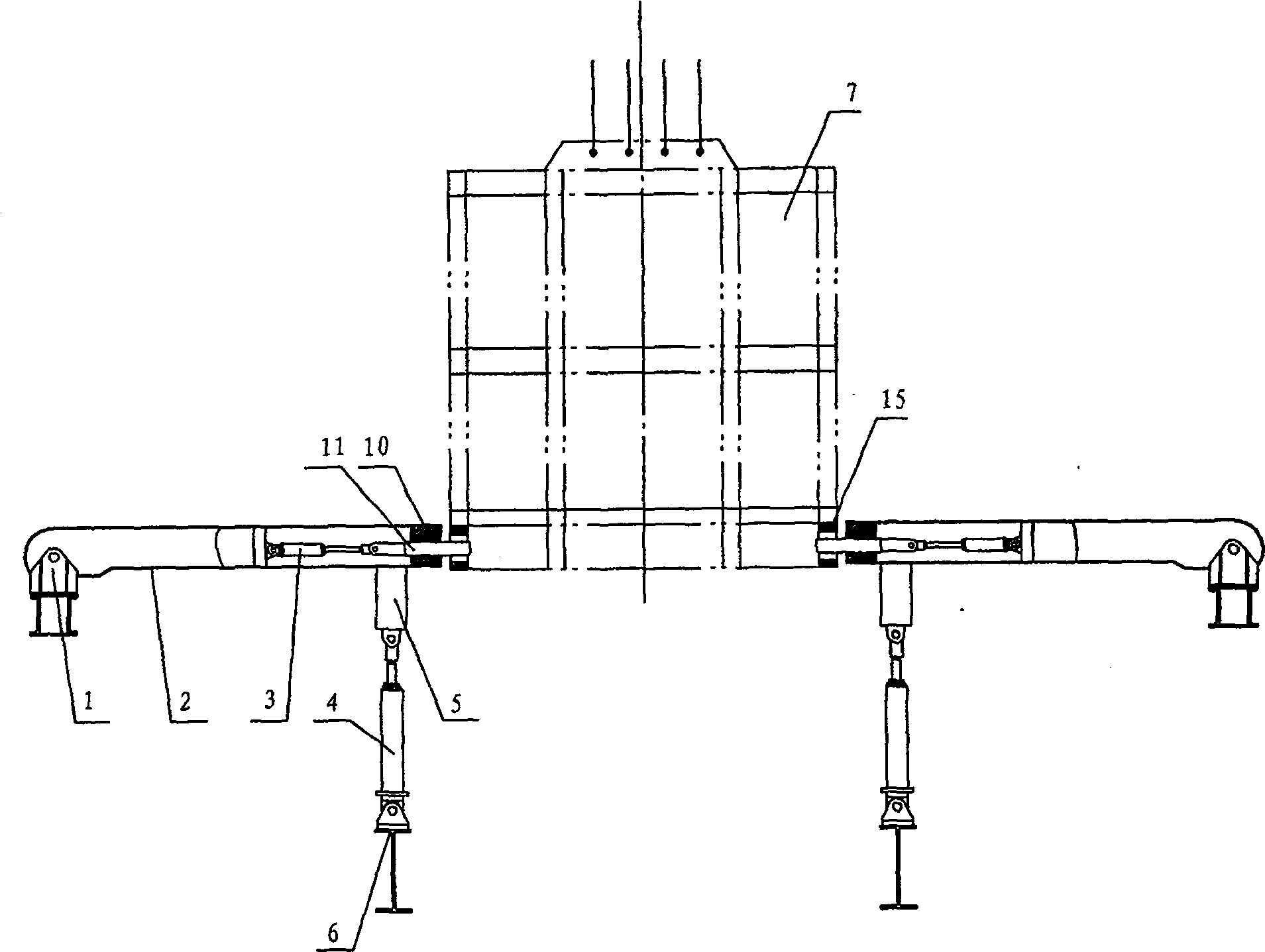

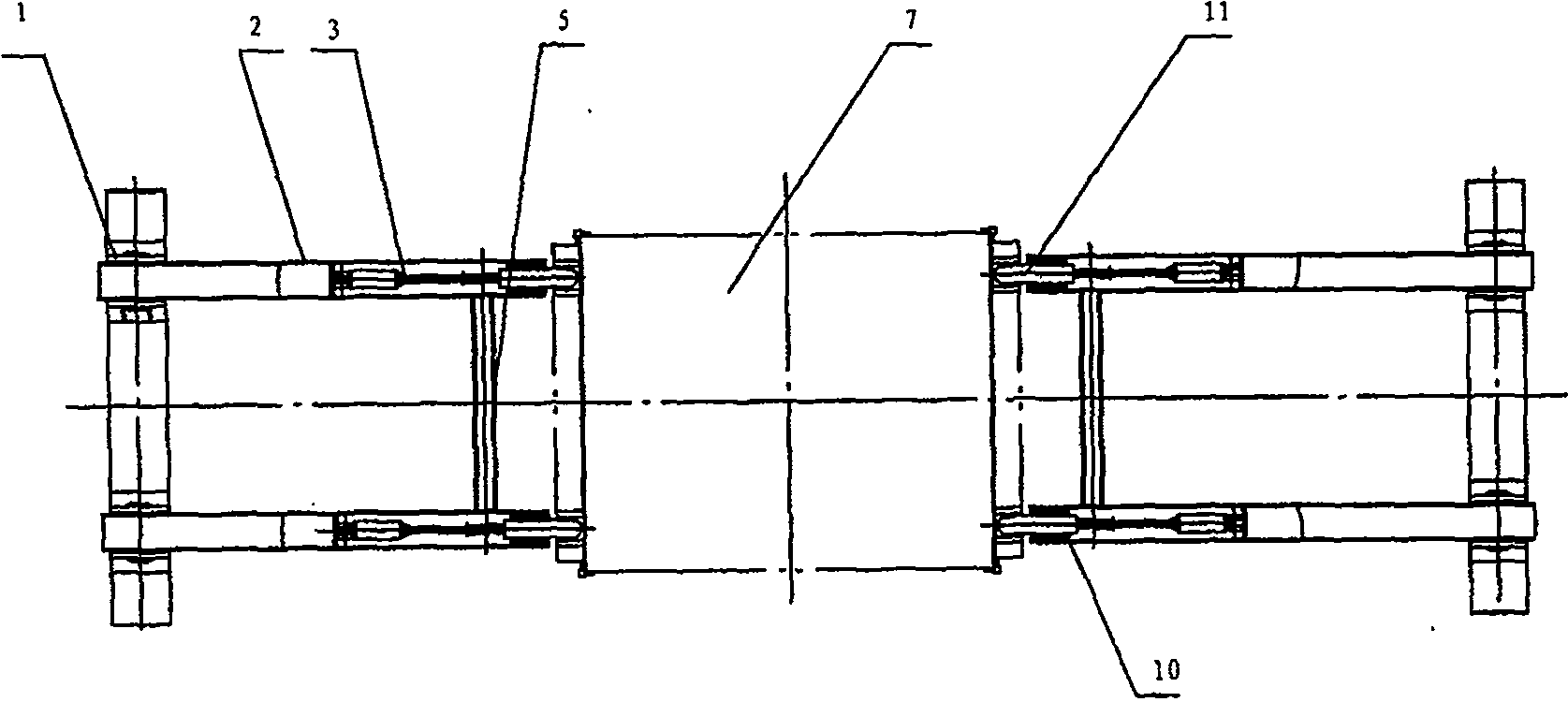

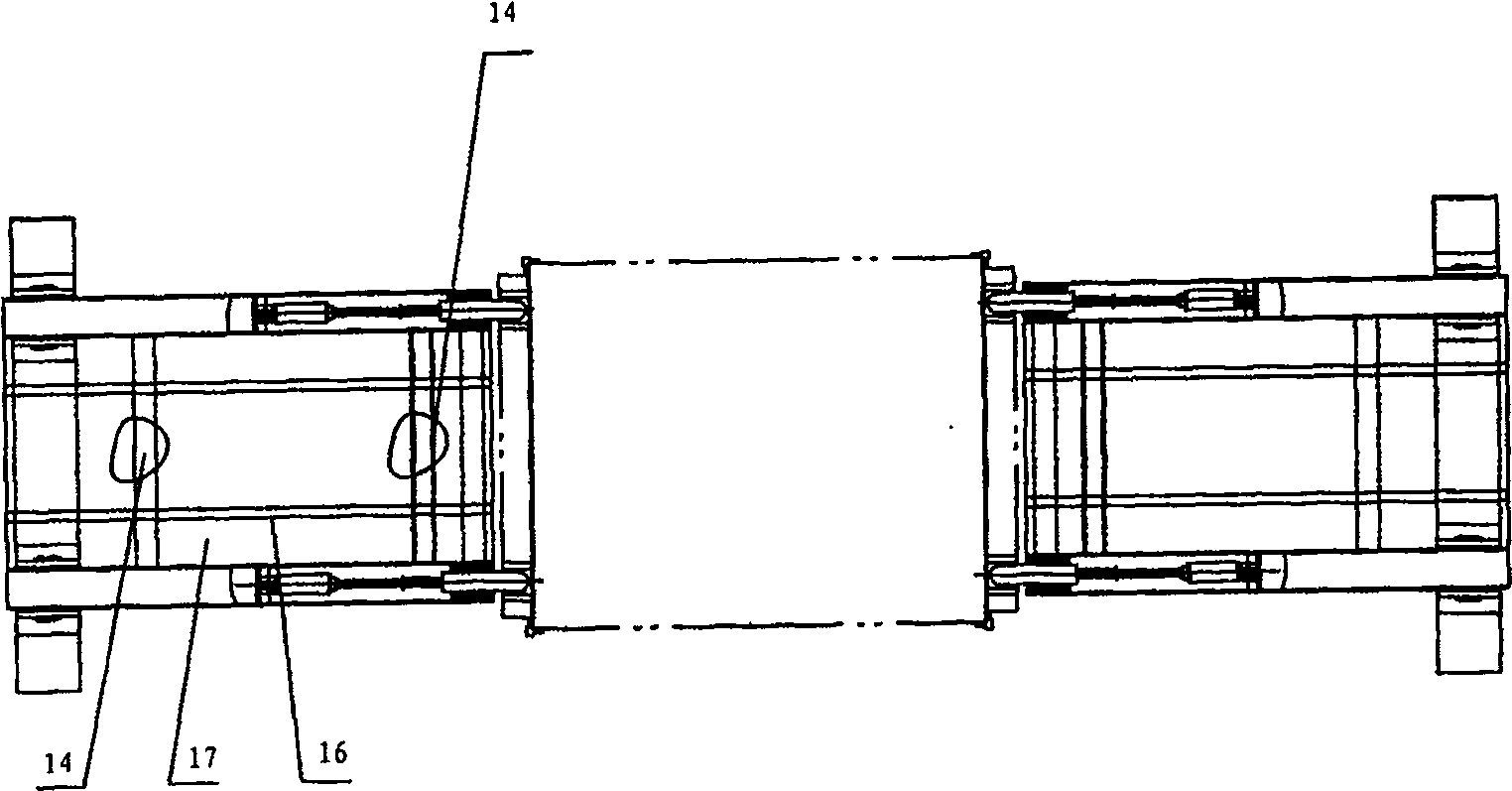

[0019] Example 1: The tank stabilization device for lifting the vertical shaft cage is used in conjunction with the shaking table 18 . Among them, the tank stabilization mechanism for the vertical shaft cage lifting is composed of a support 1, a tank stabilization arm 2, a catcher, and a buffer cylinder 4; the tank stabilization arm is hinged with the support; The rod 11 is formed, the oil cylinder 3 is hinged on the tank stabilizing arm, the oil cylinder 3 is hinged with the push rod 11, and the push rod 11 passes through the sliding seat 10 at the front end of the tank stabilizing arm; the buffer cylinder 4 is supported under the front part of the tank stabilizing arm. The tank stabilization device is composed of the two sets of tank stabilization mechanisms. The tank stabilization mechanisms are arranged in parallel. The front parts of the two tank stabilization arms of the tank stabilization mechanism are connected together by a beam 5. The buffer cylinder 4 is supported on...

Embodiment 2

[0020] Example 2: The tank stabilization device of the present invention is used alone as a tank holding device. The structure of the tank stabilization device is the same as that of Example 1. The difference is that the cylinder 3 is replaced by an air cylinder, and the buffer cylinder 4 is replaced by a buffer cylinder; The device is also used symmetrically. Two sets of tank stabilization devices are arranged on the entry and exit sides of the cage respectively. The lengths of the tank stabilization arms on both sides can be the same or different depending on the actual situation. There are two identically constructed tank stabilizing arms on each side. The tank stabilizing arm is a welded steel beam, which is connected to the support 1 through a pin, and can swing up and down around the pin. The cylinder 3 of the catcher is connected to the support 8 through a pin shaft, and the front end of the cylinder is connected to the push rod 11 through a pin shaft, and the push ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com