Steel structure hydraulic elevator structure and its manufacturing method

A manufacturing method and steel structure technology, applied to elevators, elevators, transportation and packaging in buildings, etc., can solve the problems of complex processing and assembly technology, many additional configuration parts, and large occupied area, and achieve simple structure and low cost , the effect of occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Six-storey residential steel structure hydraulic elevator:

[0024] 1. Component design and manufacture:

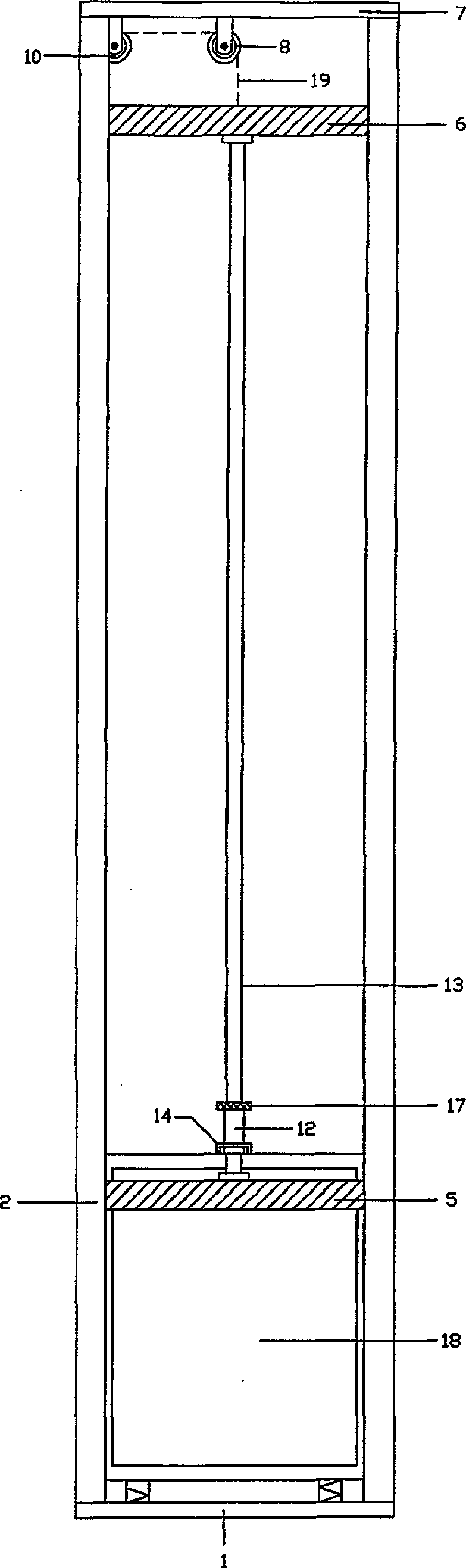

[0025] 1. Take a metal tube of length 2000mm x width 200mm x height 100mm to make a square bottom base and top base. The middle part of the top base is 2000mm x width 150mm x height 100mm. The fixed pulley with a diameter of 300mm is fixedly connected with two sets of 300mm diameter change pulleys and traction chain connectors under the frame.

[0026] 2. Take a metal tube with a length of 20000mm x width 200mm x a height of 200mm to make a structural column; take a metal square tube with a length of 1600mm x width 200mm x a height of 200mm to make a structural beam on the door, a lower structural beam, an upper structural beam, and a hydraulic cylinder positioning structure Beam; hydraulic cylinder positioning structure The middle of the beam length is provided with a 122mm diameter hydraulic cylinder hole, and both sides are provided with a 30mm diameter tractio...

Embodiment 2

[0037] Three-story hall sightseeing steel structure hydraulic elevator:

[0038] 1. Component design and manufacture:

[0039]1. Take a metal tube with a length of 1800mm x width 150mm x a height of 50mm to make a square bottom base and a top base. The middle part of the top base is 1800mm x width 150mm x height 50mm. The fixed pulley with a diameter of 300mm is fixedly connected with two sets of 300mm diameter change pulleys and traction chain connectors under the frame.

[0040] 2. Take metal tubes with length 15000mm x width 150mm x height 150mm to make structural columns; take metal square tubes with length 1500mm x width 150mm x height 150mm to make door structural beams, lower structural beams, upper structural beams, and hydraulic cylinder positioning structures Beam; hydraulic cylinder positioning structure The middle of the beam length is provided with a 100mm diameter hydraulic cylinder hole, and both sides are provided with a 30mm diameter traction chain hole.

[...

Embodiment 3

[0051] Villa sightseeing steel structure hydraulic elevator:

[0052] 1. Component design and manufacture:

[0053] 1. Take a metal tube of length 1500mm x width 150mm x height 50mm to make a square bottom base and top base. The middle part of the top base is 1500mm x width 150mm x height 50mm. The fixed pulley with a diameter of 300mm is fixedly connected with two sets of 300mm diameter change pulleys and traction chain connectors under the frame.

[0054] 2. Take a metal tube with a length of 7000mm x width 120mm x a height of 120mm to make a structural column; take a metal square tube with a length of 1060mm x width 120mm x a height of 120mm to make a structural beam on the door, a lower structural beam, an upper structural beam, and a hydraulic cylinder positioning structure Beam; hydraulic cylinder positioning structure The middle of the beam length is provided with a hydraulic cylinder hole with a diameter of 80mm, and a hole with a diameter of 30mm is provided on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com