Brush holder for an electrical machine

A brush holder and brush technology, which is applied to circuits, current collectors, electrical components, etc., can solve problems such as brush noise, and achieve the effect of simple structure and large cost saving potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

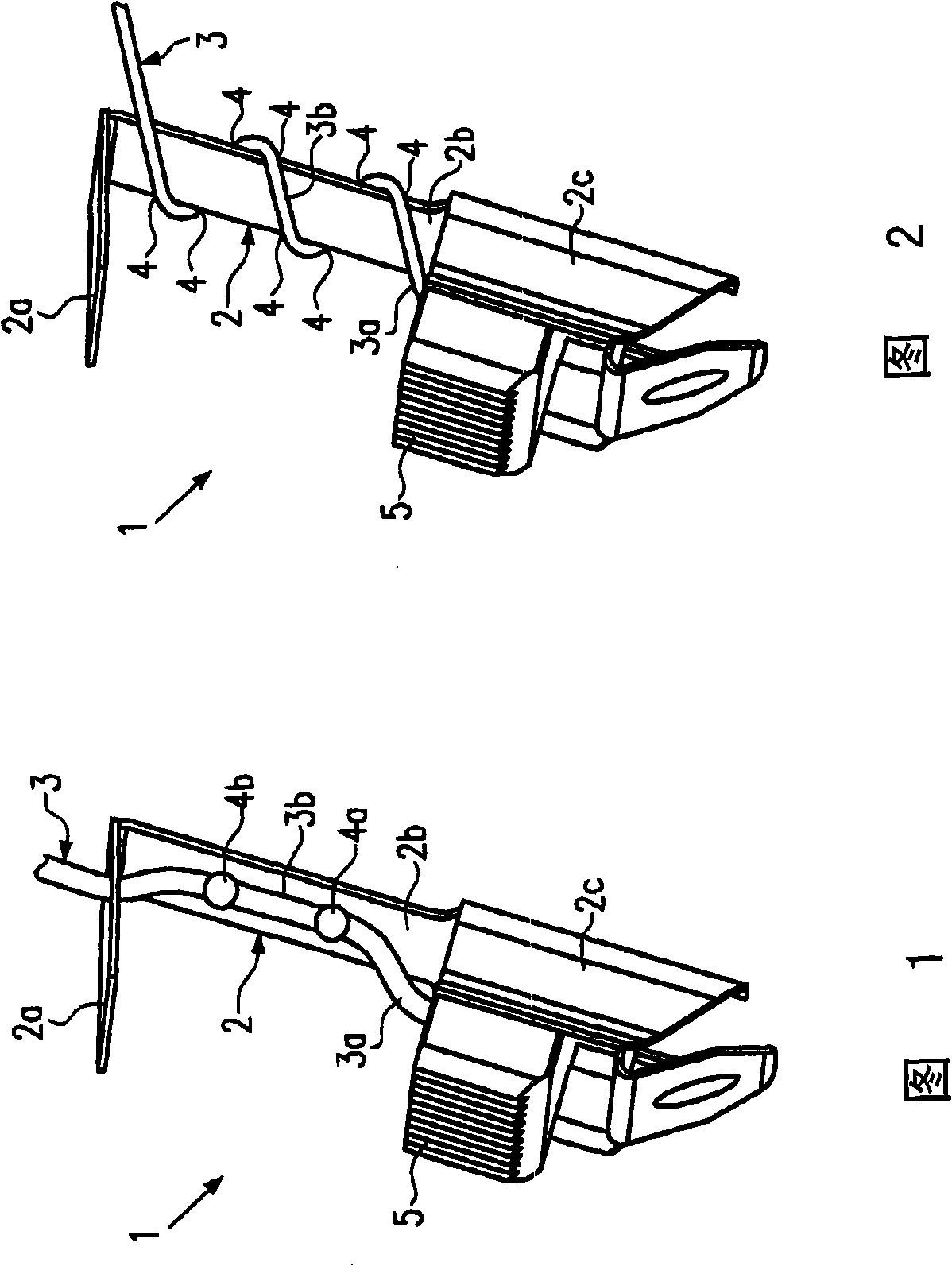

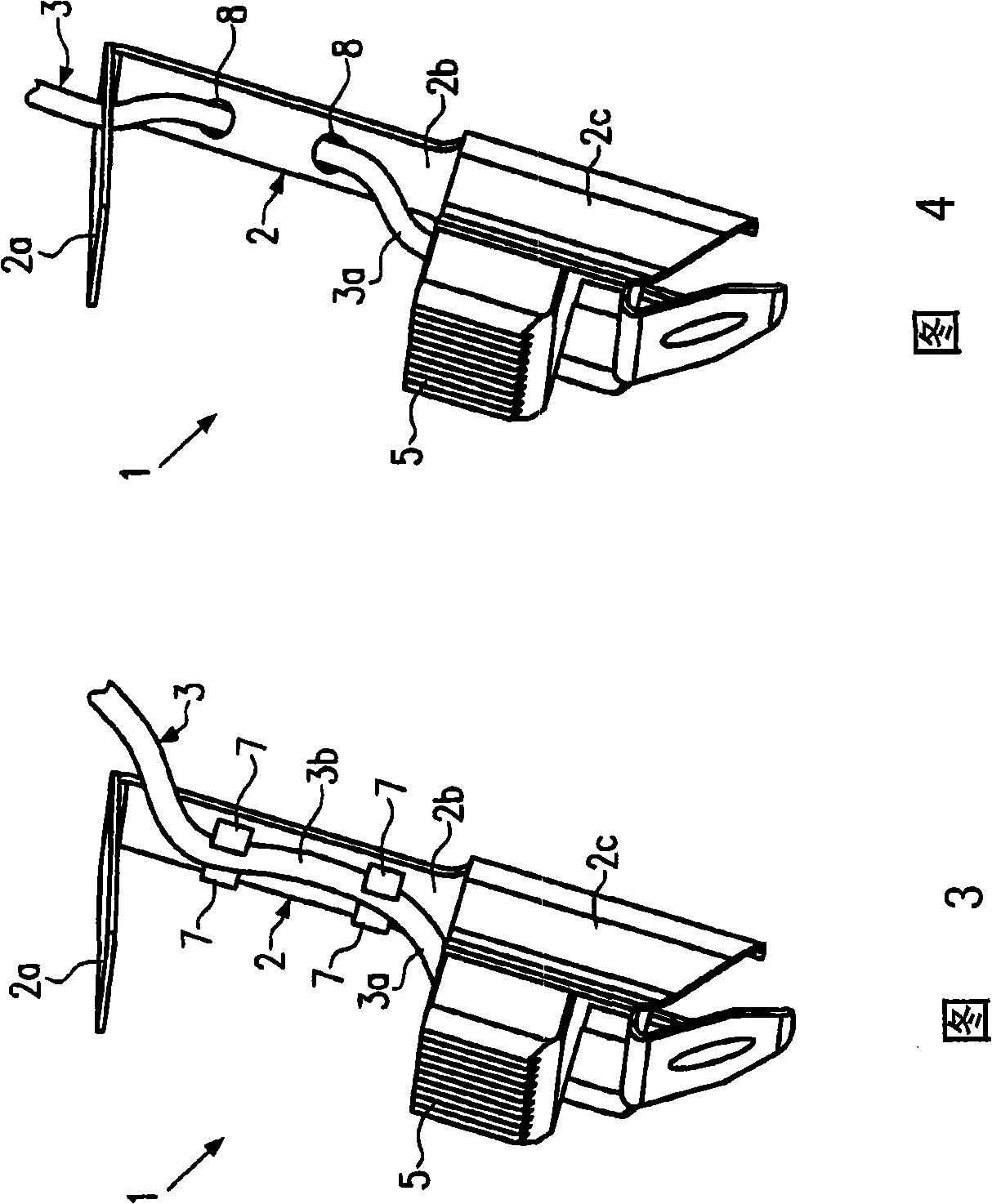

[0020] Refer below figure 1 A brush holder 1 according to a first exemplary embodiment of the invention will be described. The brush holder 1 essentially comprises a spring rod 2 which is made, for example, of spring steel or plastic with elastic properties. The spring lever 2 includes a fastening region 2 a with which the spring lever 2 is fastened, for example, to the housing of the electric motor. The fastening region 2 a can be clamped, for example, into a housing region or cast into the housing region by injection molding. Furthermore, the spring rod 2 also includes a rod region 2b which extends at a predetermined angle with respect to the fixing region 2a. At the end of the shaft region 2b, a bearing region 2c for supporting a brush 5 is provided. Such as figure 1 As shown, the brush 5 protrudes slightly forward from the support area 2c and provides electrical contact with a rotating structural part of the motor.

[0021] The brushes 5 can be supplied with current v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com