Ink nozzle wiping device and ink nozzle cleaning method

An inkjet head, cleaning technology, applied in printing and other directions, can solve problems such as damage, reduced service life, frequent wiping actions, etc., to achieve the effect of extended protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

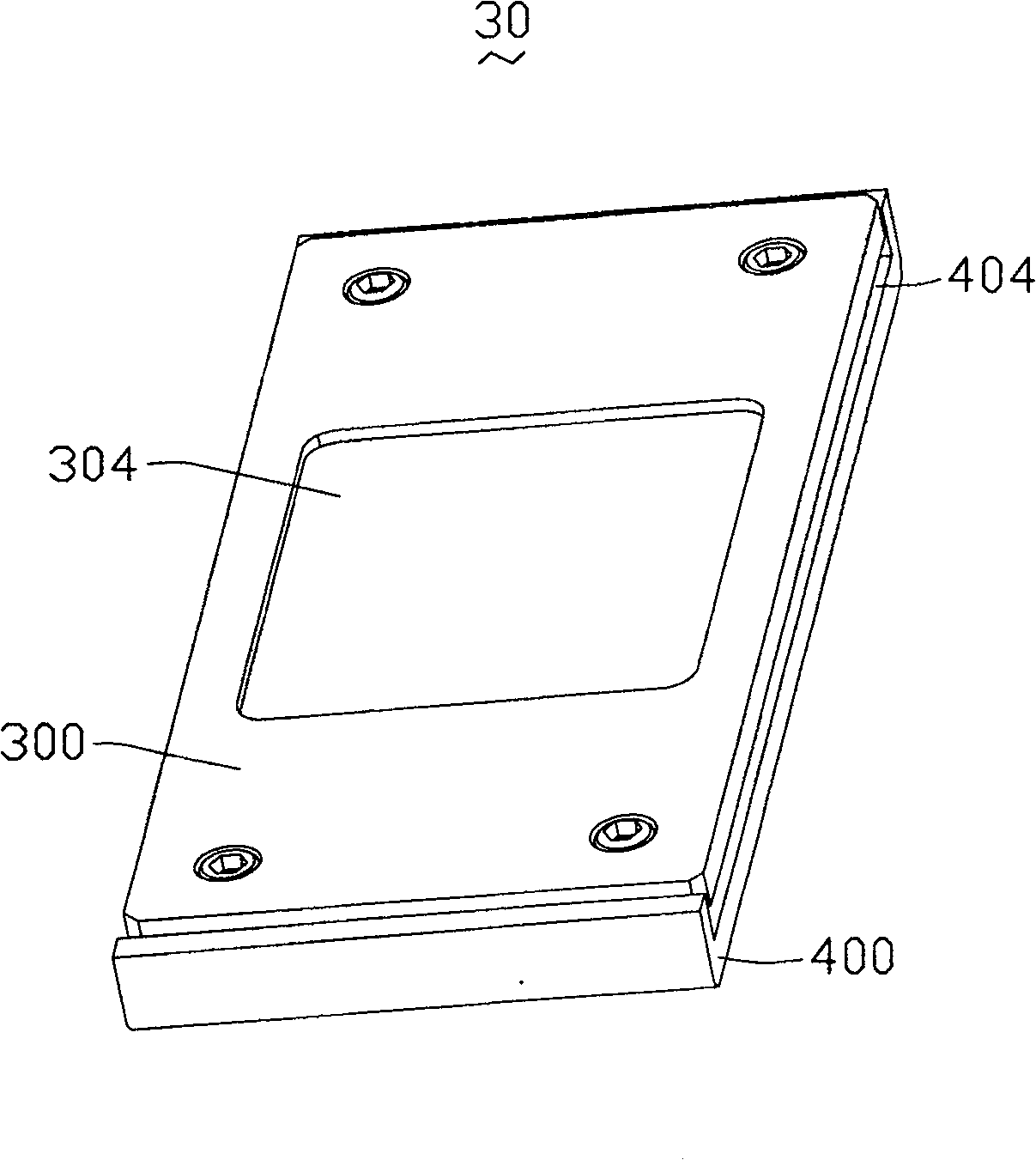

[0021] see figure 2 , a schematic side view of an inkjet head wiping device 1 provided in the first embodiment of the present invention. The inkjet head wiping device 1 includes: a wiping medium 10 , a tension device and a support device 30 .

[0022] The wiping medium 10 is in direct contact with the inkjet head (detailed later) during the cleaning process, and is used to clean the dirt and residual ink on the surface of the inkjet head, so as to ensure the cleanliness of the inkjet head. The wiping medium 10 can be made of fibers in two or more directions or polymer fibers, such as polyester fibers. The fiber is bright, smooth, soft and not easy to deform, which can better protect the inkjet head.

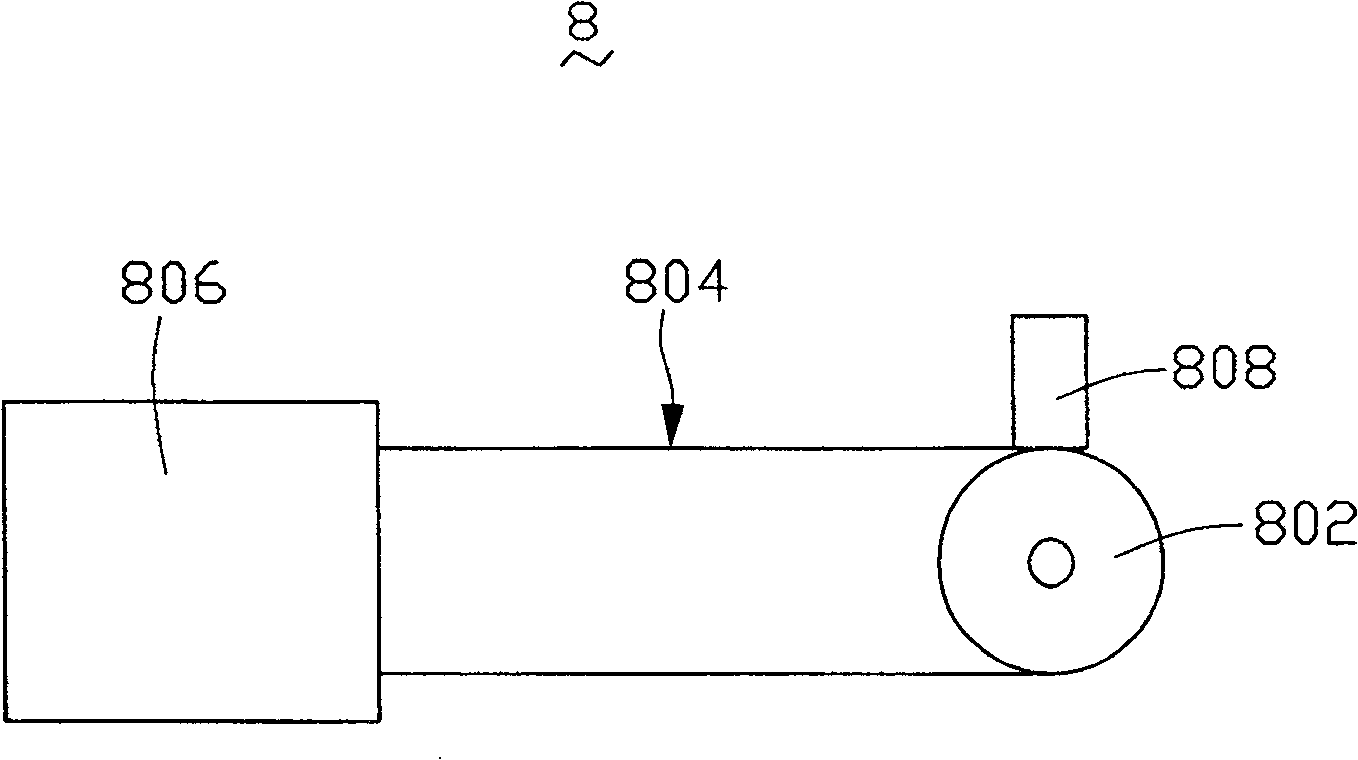

[0023] The tension device is disposed at both ends of the supporting device 30 , each end is provided with a pair of axles 202 and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com