A micro-motor rotor commutator assembly device

A technology for assembling devices and commutators, applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve the problems of rotor core damage, large resistance, and one-to-one winding slots, etc., to achieve The effect of avoiding displacement, smooth guiding and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-6 The application is described in further detail.

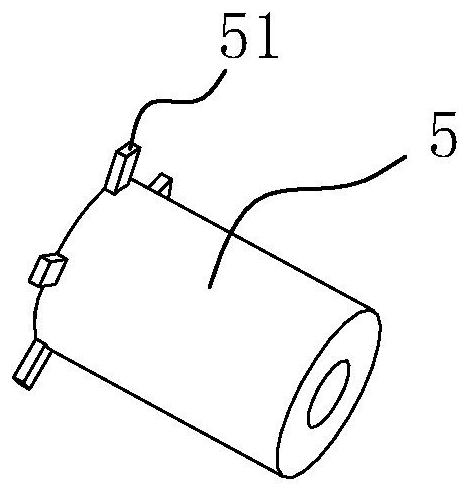

[0037] Such as figure 1 As shown, the micro-motor rotor 4 mainly includes a rotor core 41 and a rotor shaft 43 running through the center of the rotor core 41. The side wall of the rotor core 41 is provided with several winding slots 42, and at one end of the rotor core 41 The commutator 5 is plugged into the rotor shaft 43, and the copper wire wound in the winding groove 42 needs to be connected with the commutator 5. In order to improve the connection effect of the copper wire, as figure 2 As shown, at present, on the commutator 5, the circumferential array is opposite to the hanging lugs 51 of the winding slots 42 one by one. The side wall is extruded and deformed, thereby clamping the copper wire for fixing.

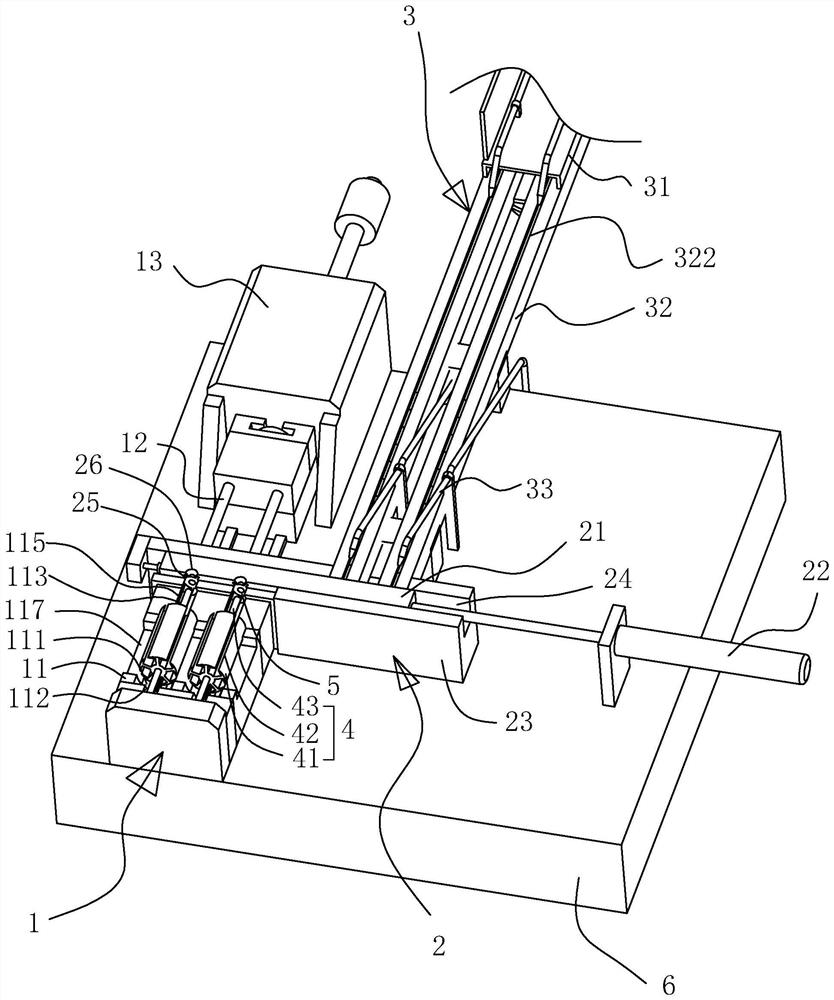

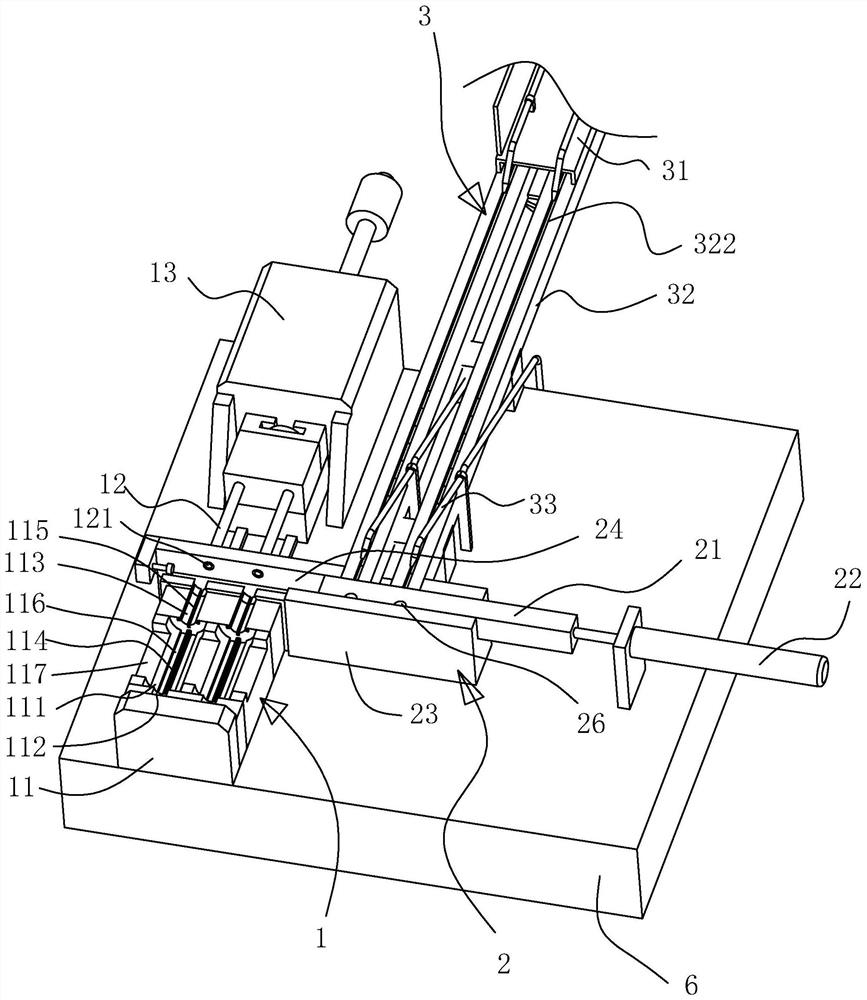

[0038] The embodiment of the application discloses a micro-motor rotor commutator assembly device. refer to figure 1 , 3 , comprising a frame 6 and a feeding mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com