Method for manufacturing cobalt stibium antimonide based thermoelectric device

A technology for thermoelectric devices and manufacturing methods, which is applied in the field of connection between cobalt antimonide thermoelectric materials and electrodes, and in the field of preparation of cobalt antimonide CoSb3-based thermoelectric devices. Fast speed and life-prolonging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

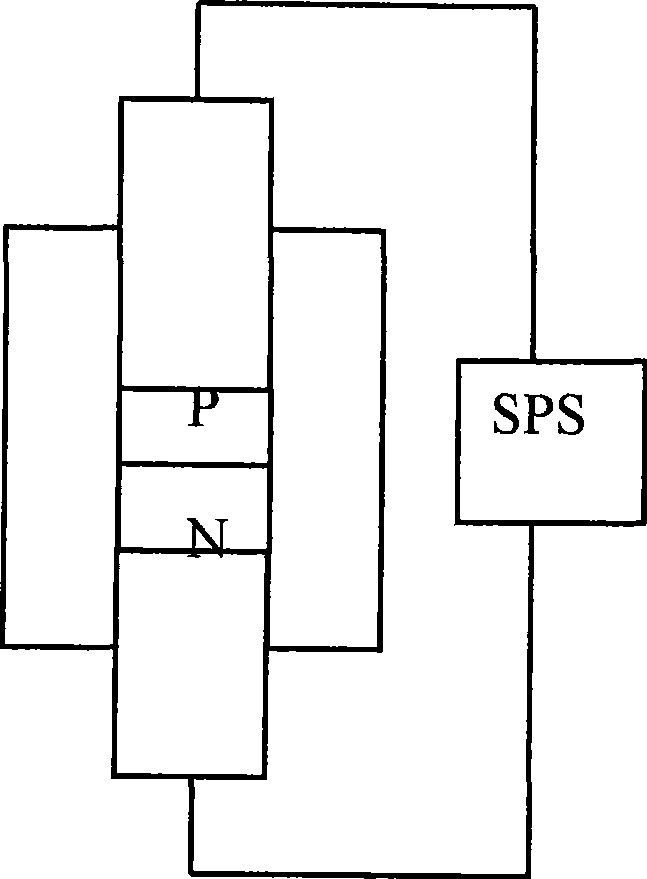

[0028] First, a 12×12×14mm P-N thermoelectric block was prepared in a square mold, and after being turned over 90°, the two end faces perpendicular to the PN interface were roughly ground to 12×12×12mm, and then ultrasonically cleaned in ethanol. Next, Mo was plasma-sprayed on both end surfaces for about 5 seconds to form a Mo diffusion barrier layer with a thickness of about 10 μm. Put the P-N type thermoelectric block back into the square mold, put the cut Ag-Cu solder piece and Mo-Cu electrode into the mold in turn on the P-N type thermoelectric block, and perform SPS connection. The sintering pressure is 15MPa, and the heating rate is 200°C / min, keep warm at 550°C for 30 seconds, then slowly lower the temperature, the cooling rate is controlled at 100°C / min, and the welding of the high-temperature end electrode is completed. Put the P-N type thermoelectric block connected with the high-temperature electrode on the Mo layer at the low-temperature end and then vacuum sputter...

Embodiment 2

[0030] First, a P-N type thermoelectric block of 8×8×10 mm was prepared in a square mold, and after being turned over 90°, the two end faces perpendicular to the PN interface were roughly ground to 8×8×8 mm, and the same as in Example 1 Methods and conditions The P-N type thermoelectric block is treated and plasma sprayed, and the P-N type thermoelectric block is put back into the square mold, and the cut Ag-Cu soldering piece and Mo-Cu electrode are put into the mold in turn. P-N type thermoelectric block On the block, SPS connection is carried out, the sintering pressure is 20MPa, the heating rate is 250°C / min, the temperature is kept at 550°C for 45 seconds, and then the temperature is slowly lowered, and the cooling rate is controlled at 150°C / min, and the welding of the high-temperature end electrode is completed. Put the P-N type thermoelectric block connected with the high-temperature electrode on the Mo layer at the low-temperature end and then vacuum sputter a Ni layer...

Embodiment 3

[0032] First, a 6×6×8mm P-N thermoelectric block was prepared in a square mold, and after being turned over 90°, the two end faces perpendicular to the PN interface were roughly ground to 6×6×6mm, and the same as in Example 1 Methods and Conditions Treat the P-N type thermoelectric block, plasma spray W on both ends for about 5 seconds, and form a W diffusion barrier layer with a thickness of about 30 μm. Put the P-N type thermoelectric block back into the square mold, put the cut Ag-Cu solder piece and Mo-Cu electrode into the mold in turn on the P-N type thermoelectric block, and perform SPS connection. The sintering pressure is 15MPa, and the heating rate is 250°C / min, keep warm at 550°C for 60 seconds, then slowly lower the temperature, the cooling rate is controlled at 150°C / min, and the welding of the high-temperature end electrode is completed. Put the P-N type thermoelectric block connected with the high-temperature electrode on the Mo layer at the low-temperature end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com