Toilet bowl with acrylic and glass fiber composite structure and manufacturing method thereof

A manufacturing method and composite structure technology, which is applied in the field of sanitary ware, can solve the problems of difficulty in uniform thickness of double-layer hollow, high cost, and difficulty in manufacturing double-sided interlayer inner shells, etc., and achieve saving of FRP materials, convenient operation, and reduced workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

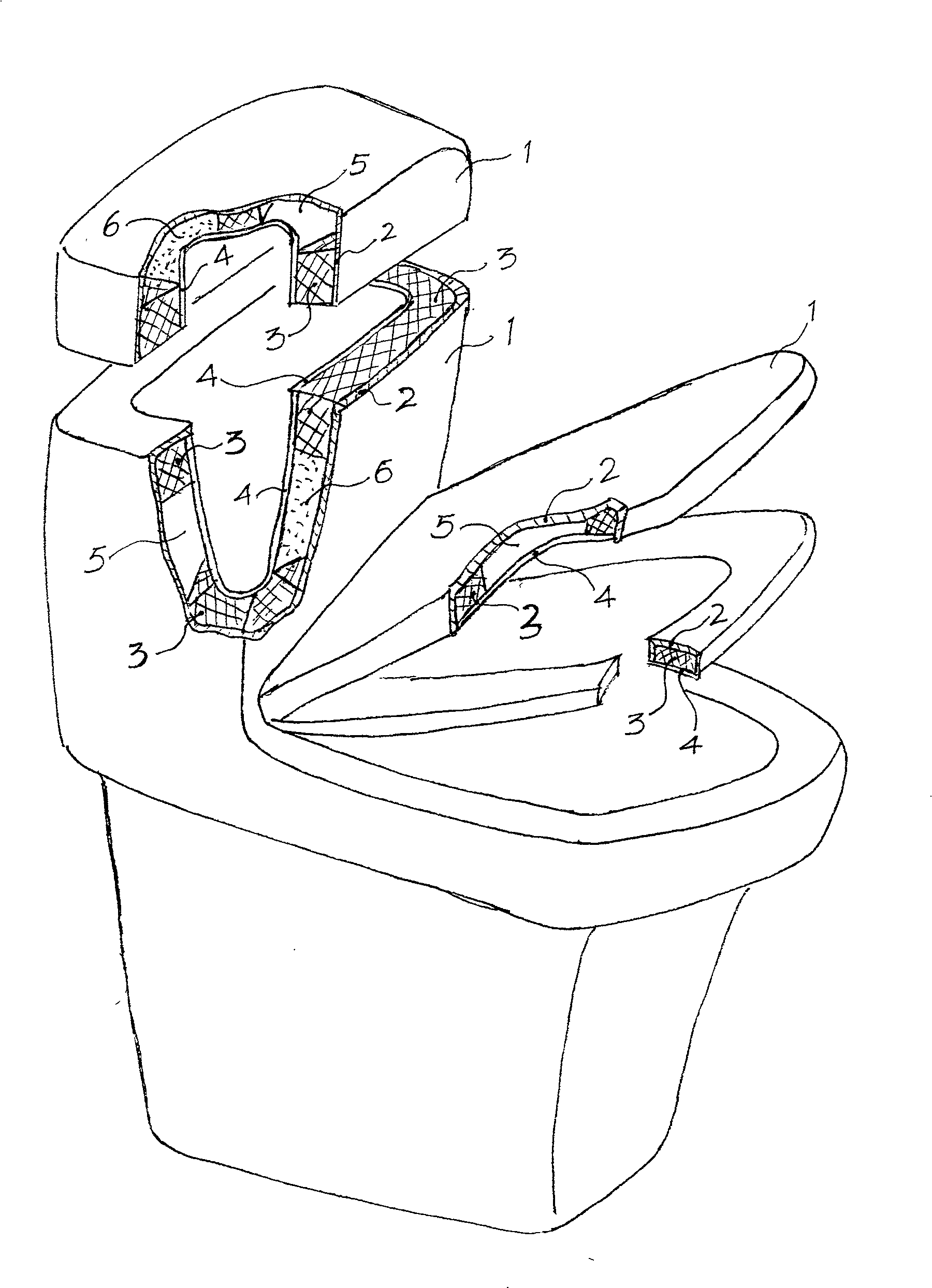

[0040] Embodiment 1: acrylic and glass fiber reinforced plastic composite structure toilet and its manufacturing method with three-layer structure type main components.

[0041] The main part is the toilet manufacturing method of acrylic-pasted fiberglass-fiberglass or acrylic three-layer structure, and the toilet made by this method.

[0042] The manufacturing method of the above-mentioned acrylic and glass-steel composite structure toilet, including the water tank cover, the water tank body, and the toilet cover are the manufacturing method steps of the toilet with three-layer structure as follows:

[0043] a. Manufacture molds: According to the design of the main parts of the toilet, the water tank cover, the water tank body, and the toilet cover, two molds, one female mold and one male mold with matching sizes, are manufactured; however, the toilet cover does not need a male mold. The mold surface should be polished smooth. The convex surface of the male mold is smaller t...

Embodiment 2

[0066] Embodiment 2: A toilet with a composite structure of acrylic and glass fiber reinforced plastics with gaps in the middle part of the main components of the three-layer structure and its manufacturing method.

[0067] Change the step "d, paste FRP middle layer" of embodiment 1 to paste the same or substantially the same thickness of FRP at each position: apply a FRP layer of the same or substantially the same thickness around the formed part of the outer layer acrylic material, The middle part of the formed part of acrylic material is coated with a thinner FRP layer than the surrounding ones, so that the thickness of the surrounding FRP layer is much greater than that in the middle position. Then follow the step "e, bonding the forming part layer of the inner layer of FRP material or the forming part layer 4 of the inner layer of acrylic material" to obtain a structure in which the position of the middle thin FRP layer is a gap 5 . Others are the same as embodiment 1, th...

Embodiment 3

[0071] Embodiment 3. There are three-layer structure and four-layer structure composite structure toilet and its manufacturing method.

[0072]Apply embodiment 2 on the outer layer acrylic forming part to be thick around, and after the middle thin fiberglass layer, spray or cast foam material 6 on the middle thin fiberglass layer, promptly fill in the gap 5 with polyurethane foam material, and stick Connect the forming part layer of the inner fiberglass material or the forming part layer 4 of the inner acrylic material, on the surface of the thick glass fiber reinforced plastic and the polyurethane foam surface, obtain the main part of the toilet with the polyurethane foam material filled in the middle space 5 of the main part of the toilet . Others are the same as in Example 2. The structure of the main parts of this acrylic toilet is:

[0073] The surrounding layers are: outer layer of acrylic - middle layer of coated FRP - inner layer of FRP, or

[0074] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com