Power boiler burning optimization method and device based on infra red radiation energy signal

A technology for combustion optimization and power plant boilers, applied in the direction of combustion control, control system, steam generation, etc., to overcome pressure and flow fluctuations, improve load response speed, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

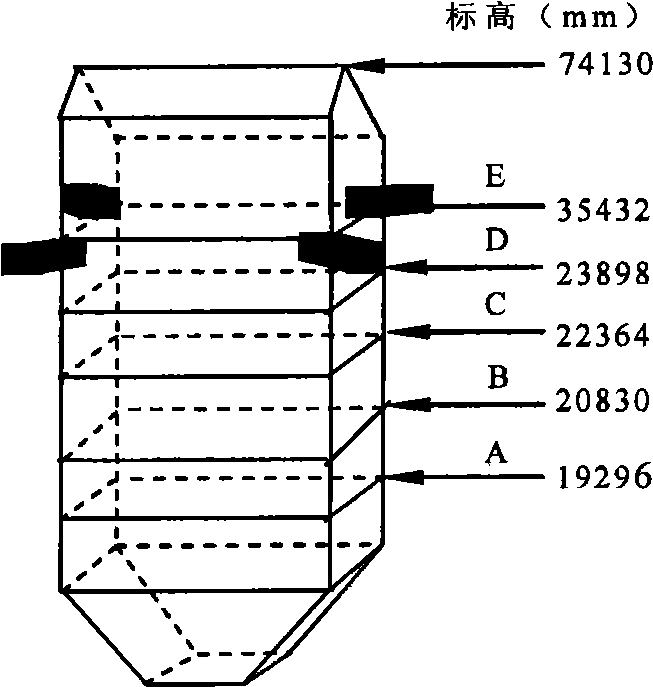

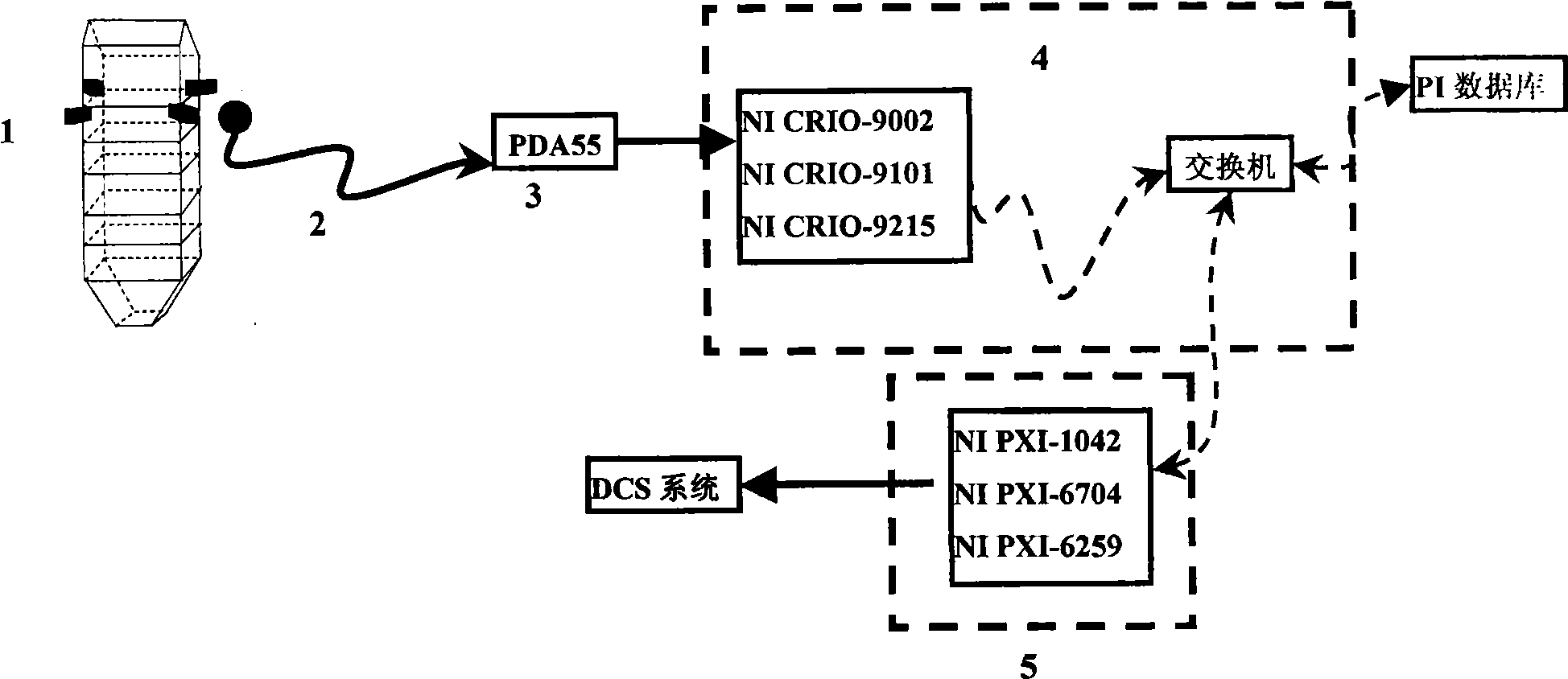

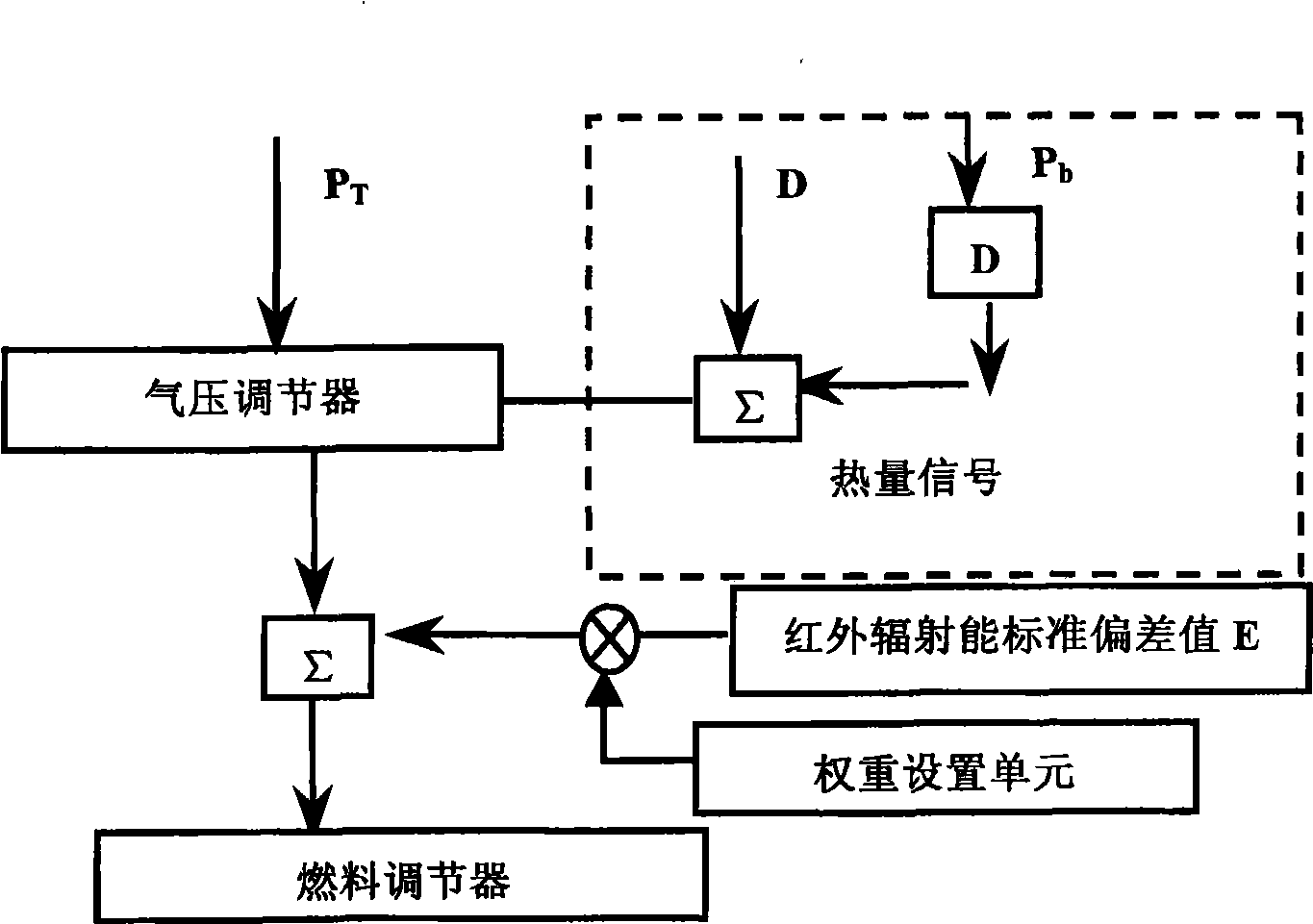

[0020] Such as figure 1 , figure 2 As shown, the near-infrared radiant energy sensor 1 is installed at the four corners of the boiler at a height of 35.432m. The furnace radiant energy is obtained by the near-infrared radiant energy sensor 1, transmitted to the photoelectric conversion element PDA55 3 through the optical fiber 2, and converted through the photoelectric conversion element. The BNC connector outputs a 0-10V voltage signal, which is then transmitted to the control center through a network cable. The NICRIO-9002 in the lower computer data acquisition and transmission control module 4 is an on-site data acquisition lower computer, used for data acquisition and transmission control, and communicates with the upper computer data analysis and control signal output module 5 through the TCP / IP protocol. The real-time furnace radiant energy signal input by the lower computer is connected to the switch through the network cable. NI PXI-1042 uses the TCP / IP network to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com