GaN device based on component-gradient GaN MISFET and preparing method thereof

A component and device technology, applied in the field of microelectronics, can solve the problems that restrict the improvement of device performance, high surface states and defects, and poor device withstand voltage characteristics, so as to achieve the goal of increasing power density, reducing leakage current, and reducing state density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

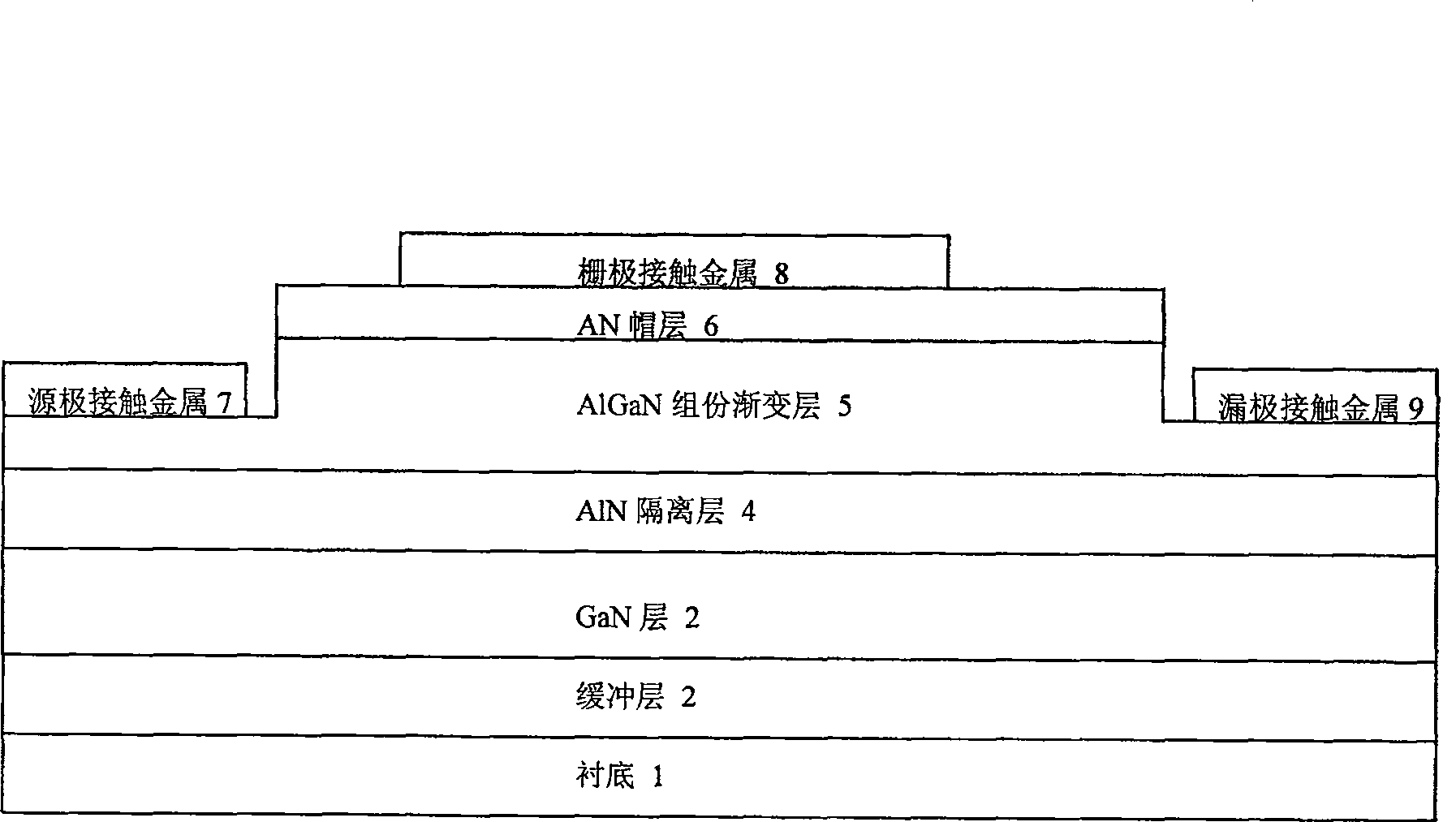

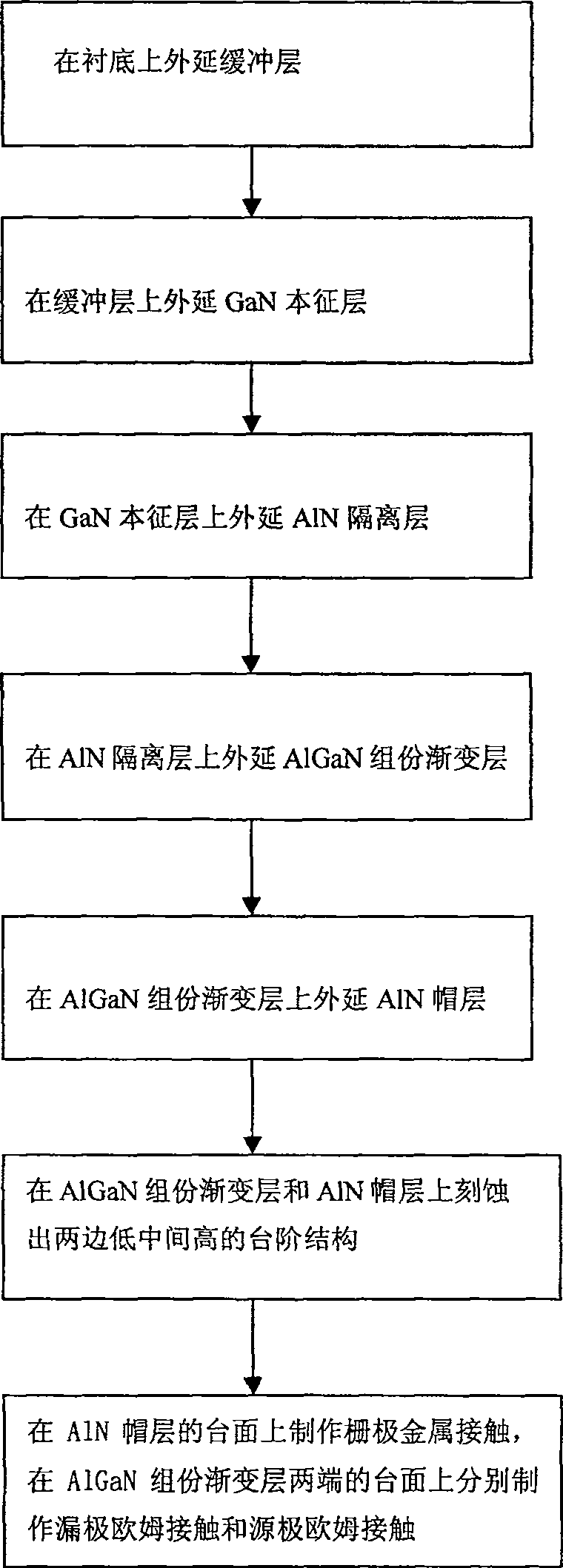

[0038] The process of manufacturing a high-power GaN MISFET device of a silicon carbide substrate by using the method of the invention.

[0039] In the first step, a layer of AlN material with a thickness of 50 nanometers is deposited on the SiC substrate material by using the MOCVD method at a temperature of 1050 degrees and a pressure of 20 Torr, as a buffer layer for subsequent growth of GaN materials.

[0040] In the second step, a GaN intrinsic layer with a thickness of 2 microns is deposited on the buffer layer by using MOCVD technology at a temperature of 1000 degrees and a pressure of 20 Torr.

[0041] The third step is to deposit an AlN material layer with a thickness of 1 nanometer on the GaN intrinsic layer by using MOCVD technology at a temperature of 1000 degrees and a pressure of 20 Torr.

[0042] The fourth step is to use MOCVD technology on the AlN material layer to deposit an AlGaN composition graded material layer with a thickness of 10 nanometers and an Al c...

Embodiment 2

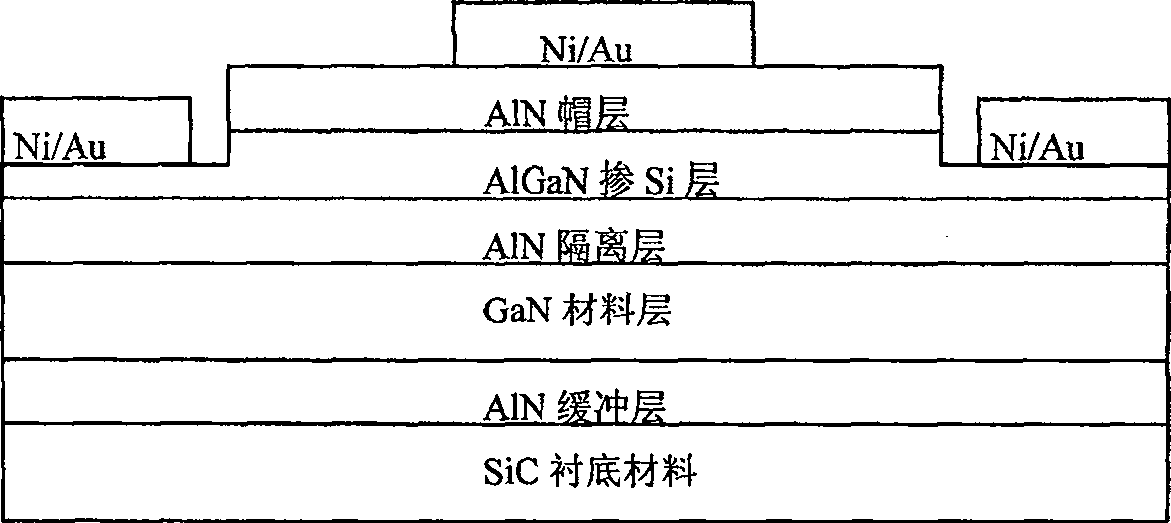

[0047] A high-power GaN MISFET device process of manufacturing a sapphire substrate by using the method of the invention.

[0048] The first step is to use MOCVD technology on the sapphire substrate material to deposit a layer of GaN material with a thickness of 100 nanometers at a temperature of 550 degrees and a pressure of 40 Torr as a buffer layer for subsequent growth of GaN materials.

[0049] In the second step, a GaN intrinsic layer with a thickness of 3 microns is deposited on the buffer layer using MOCVD technology at a temperature of 900 degrees and a pressure of 40 Torr.

[0050] In the third step, an AlN isolation layer with a thickness of 2 nanometers is deposited on the GaN intrinsic layer by using MOCVD technology at a temperature of 1000 degrees and a pressure of 20 Torr.

[0051] The fourth step is to use MOCVD technology on the AlN isolation layer to deposit an AlGaN graded layer with a thickness of 15 nanometers and an Al composition that gradually changes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com