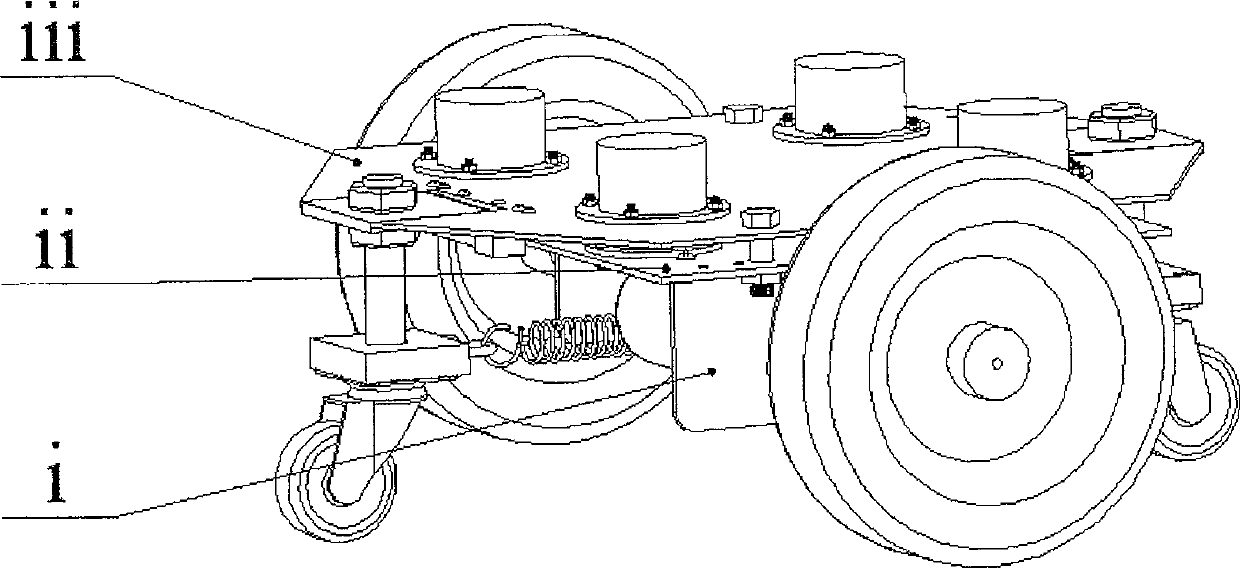

Robot vehicle body suspension system

A technology for robots and car bodies, applied in suspension, elastic suspension, vehicle components, etc., to achieve the effect of strong rollover resistance, good shock absorption performance and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

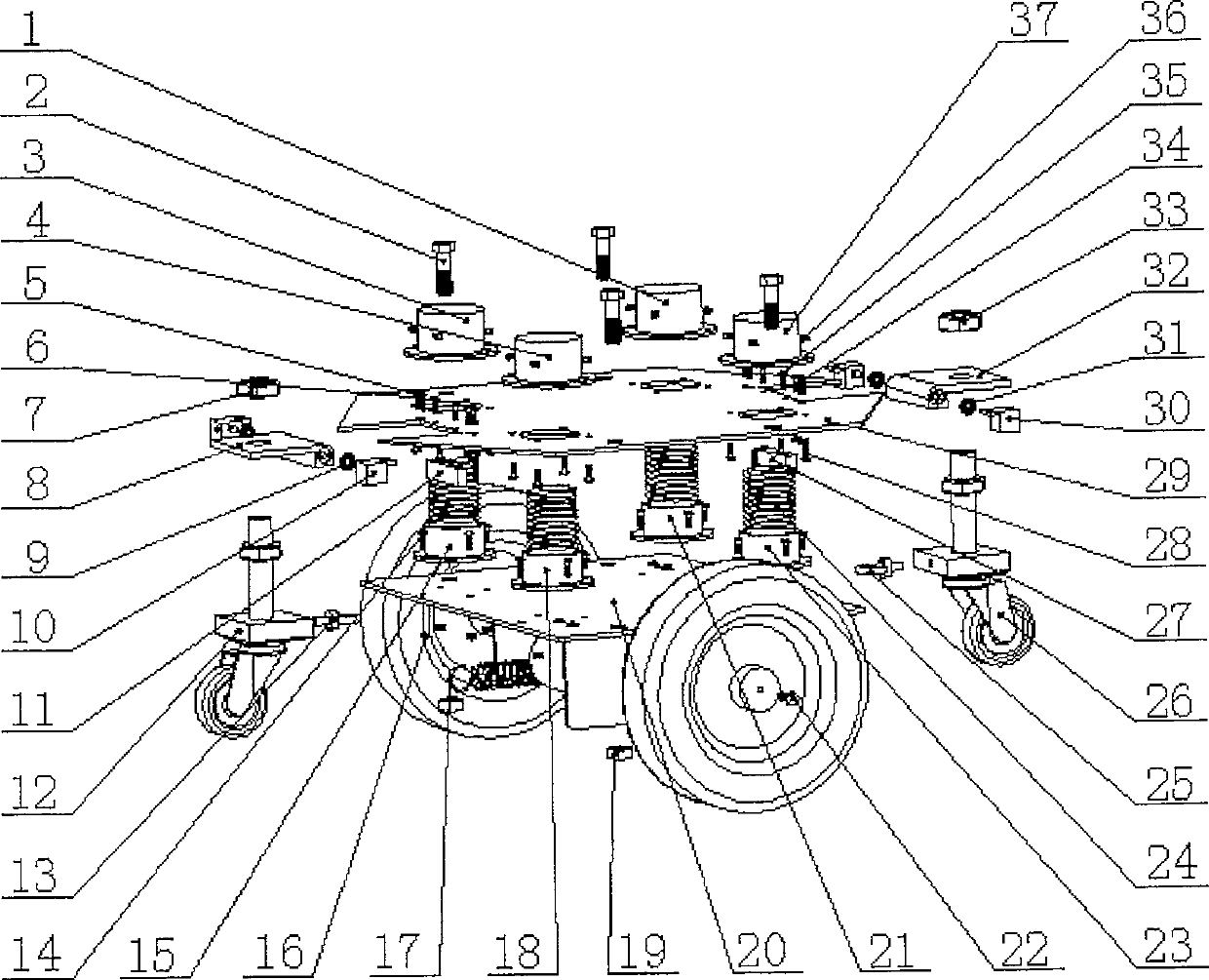

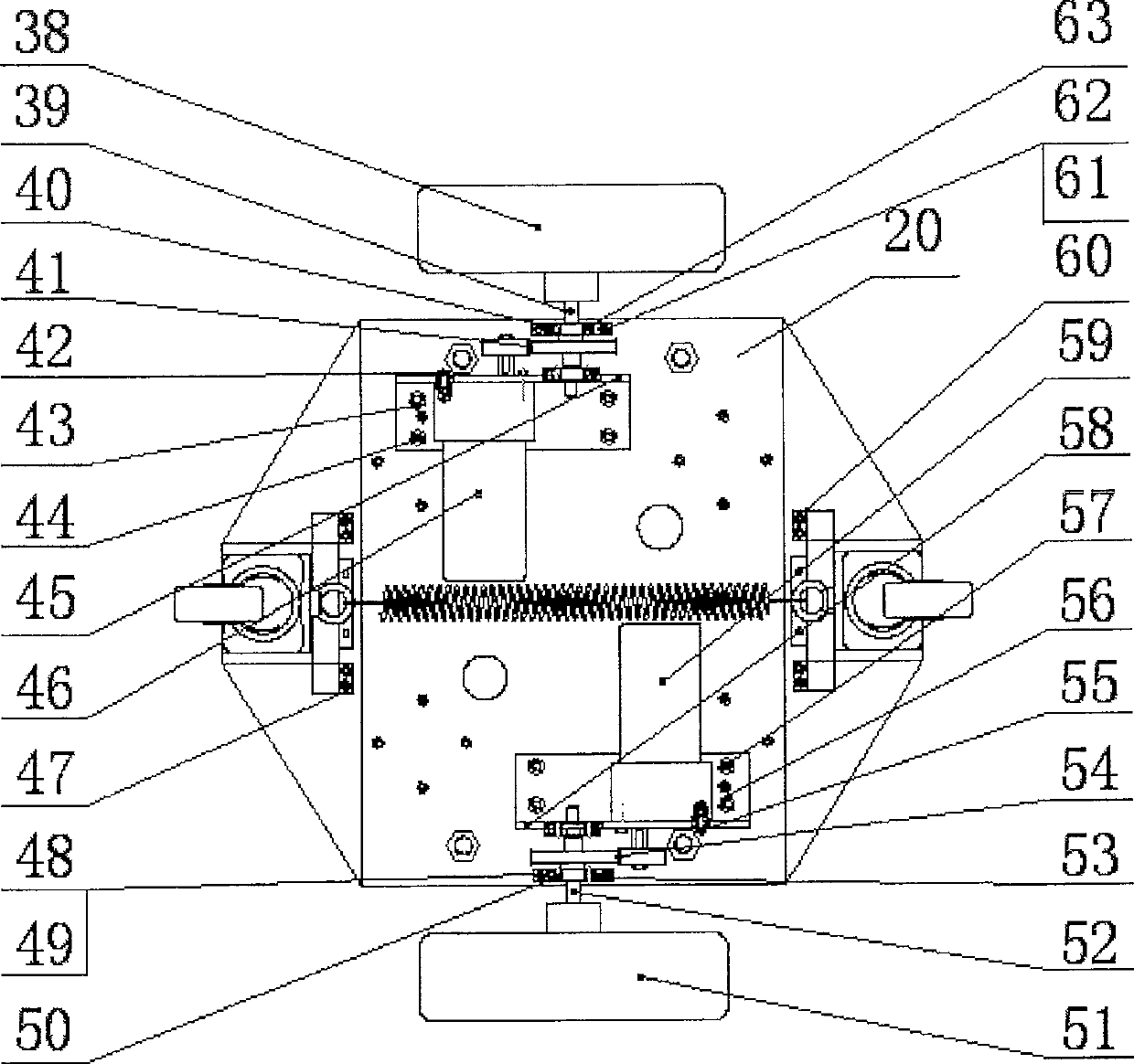

[0010] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings. When this structure turns, it adopts the driving mode of left and right two-wheel differential speed and front and rear two-wheel follow-up, and the left and right drive wheels 51, 38 are driven separately by left and right motors 59, 46; The front and rear follower wheels 26,12 of the front and rear follower support plates 32,8 can rotate around the front and rear rotation shafts 30,10, so that the height of the follower wheels has a large adjustment space, because the two follower support plates 32, 8 are respectively spaced by the front and rear limit stops 27,11 opposite to the spring stretching direction, therefore, effectively prevent the front and rear follower wheels 26,12 from being pulled to the center; the installation of the front and rear limit stops 27,11 is a technical Requirements, that is, when the front and rear follower wheels 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com