Alkali-reducing processing promotor of polyester fiber fabric

An alkali weight reduction accelerator and polyester fiber technology, which can be used in fiber processing, textiles and papermaking, etc., can solve the problems of difficult control of polyester fiber alkali weight loss, poor uniformity, and large strength loss of polyester fiber fabrics. Promote uniform penetration, increase speed, and reduce weight to treat uniform effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Alkali decrement accelerator formula is composed as follows by weight:

[0020] Polyoxyethylene-containing double quaternary ammonium salt cationic surfactant 30%

[0021] Nonionic Surfactant 8%

[0022] Water 62%

[0023] Preparation method: Dissolve the calculated amount of cationic surfactant and nonionic surfactant with a certain amount of water under heating conditions, then mix, stir evenly, and make up the remaining water.

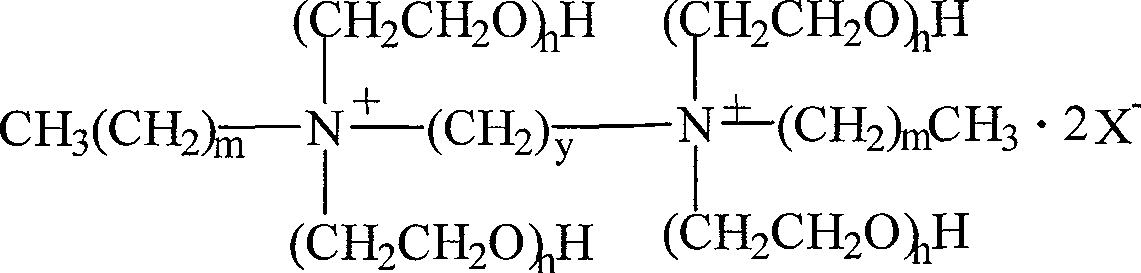

[0024] The double quaternary ammonium salt cationic surfactant structure containing polyoxyethylene group used is:

[0025]

[0026] The structure of nonionic surfactants is:

[0027] CH 3 (CH 2 ) 11 O(CH 2 CH 2 O) 12 h

Embodiment 2

[0029] Alkali decrement accelerator formula is composed as follows by weight:

[0030] Polyoxyethylene-containing double quaternary ammonium salt cationic surfactant 35%

[0031] Nonionic Surfactant 5%

[0032] water 60%

[0033] Preparation method: Dissolve the calculated amount of cationic surfactant and nonionic surfactant with a certain amount of water under heating conditions, then mix, stir evenly, and make up the remaining water.

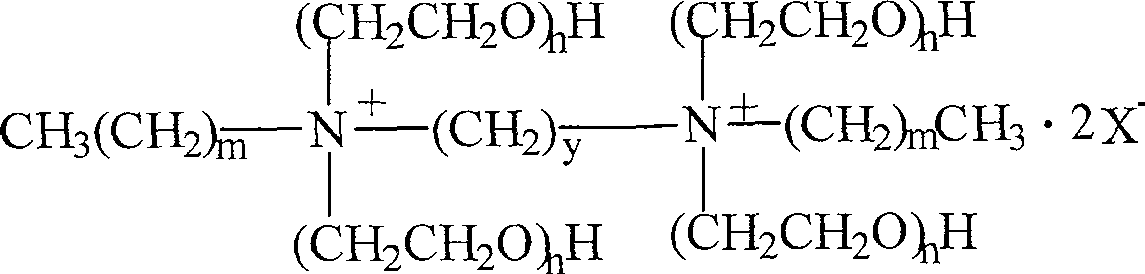

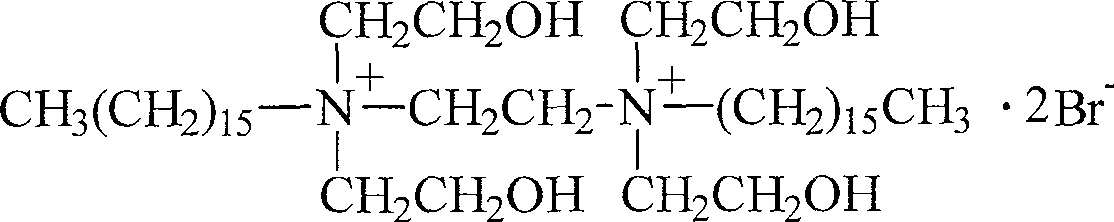

[0034] The double quaternary ammonium salt cationic surfactant structure containing polyoxyethylene group used is:

[0035]

[0036] The structure of nonionic surfactants is:

[0037] CH 3 (CH 2 ) 15 O(CH 2 CH 2 O) 15 h

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com