Preparation process of thermal stabilizer of tin methyl thio hydroacetate tin isooctoate for PVC

A technology of isooctyl tin methyl thioglycolate and isooctyl thioglycolate is applied in the field of preparation of isooctyl tin methyl thioglycolate as heat stabilizer for PVC, and can solve the problem of high process equipment conditions and energy consumption, Can not really improve product quality, loss of raw material isooctyl thioglycolate, etc., to achieve the effect of reducing energy consumption, low production equipment requirements, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Transfer the mixture of 250 grams of methyl tin chloride (dimethyl tin dichloride: monomethyl tin trichloride = 80: 20) into a 500 ml distillation flask, and use an air duct to connect with a 2000 ml reaction flask equipped with electromagnetic stirring Connect, add 450 grams of isooctyl thioglycolate and 0.2 gram of triethylamine in the reaction bottle, the reaction bottle is connected with the vacuum pump, turn on the vacuum pump and electromagnetic stirring and heat the distillation bottle to start the purification and absorption of the intermediate, and use a water bath to keep the temperature of the absorption solution at Between 35°C and 40°C, when the weight of the reaction bottle increases to 220g-223g, stop the distillation and purification, remove the distillation device, change the magnetic stirring to strong stirring, and add to the reaction bottle several times within 1 hour 120 grams of powdery sodium carbonate, the reaction temperature of adding alkali is ...

Embodiment 2

[0016] In a 2000ml reaction flask equipped with strong stirring, add 450 grams of isooctyl thioglycolate and 0.2 grams of triethylamine, start stirring and keep the temperature between 35 ° C and 40 ° C, add 223 grams of purified methyl tin chloride Compound mixture (dimethyl tin dichloride: monomethyl tin trichloride = 80: 20), after the added intermediate is completely dissolved, add 120 grams of powder in the reaction bottle several times within 1 hour Sodium carbonate, the reaction temperature of adding alkali is 40°C-45°C, after adding alkali, continue to stir for 0.5 hours, filter to obtain 668.0 g of colorless transparent oily liquid product, the yield is 99.2%.

[0017] The response is as follows:

[0018] (CH 3 ) 2 SnCl 2 +2HSCH 2 COOC 8 h 17 →(CH 3 ) 2 Sn(SCH 2 COOC 8 h 17 ) 2 +2HCl

[0019] CH 3 SnCl 3 +3HSCH 2 COOC 8 h 17 →CH 3 Sn(SCH 2 COOC 8 h 17 ) 3 +3HCl

[0020] Product Analysis Results:

[0021] Tin content: 19.45%, sulfur content: 11...

Embodiment 3

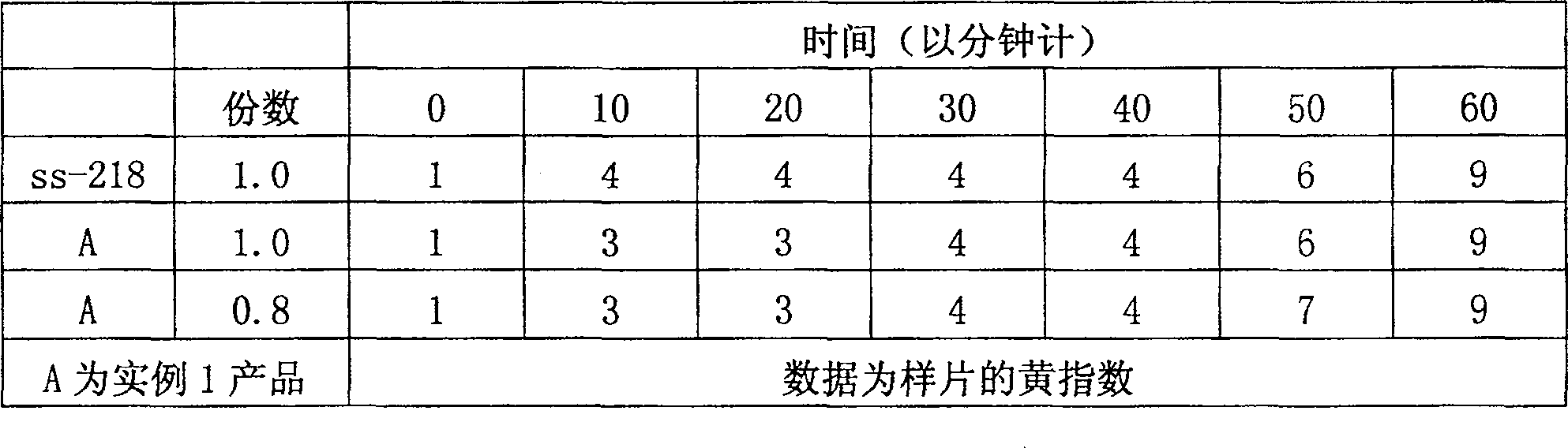

[0022] Embodiment 3: thermal stabilizer performance comparison test

[0023] Recipe: polyhydroethylene 100 parts

[0024] 2 parts isooctyl phthalate

[0025] Anti-buffer improver 5 parts

[0026] Organotin added as required

[0027] Operation: Set the roller temperature of the double-roll plastic refining machine to 165°C. After the temperature rises stably, add the primary mixed material to the upper part of the roll gap for plastic refining. Observe that the color of the material is uniform, there is no hair grain on the cross-section, the surface is smooth and has certain When the strength is reached, the rolling process is over, quickly take a one-inch square sample blank, heat the upper and lower templates of the flat filling machine press to 180°C, set the appropriate pressure, place the cut sample between the stainless steel templates, put At the center of the press workbench, start the press, close the mold and pressurize after the mold preheats th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com