Double airbag trachea cannula

A technology of tracheal cannula and double airbag, applied in the field of medical devices, can solve the problems of tracheal stenosis, erosion, mucosal ischemia and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

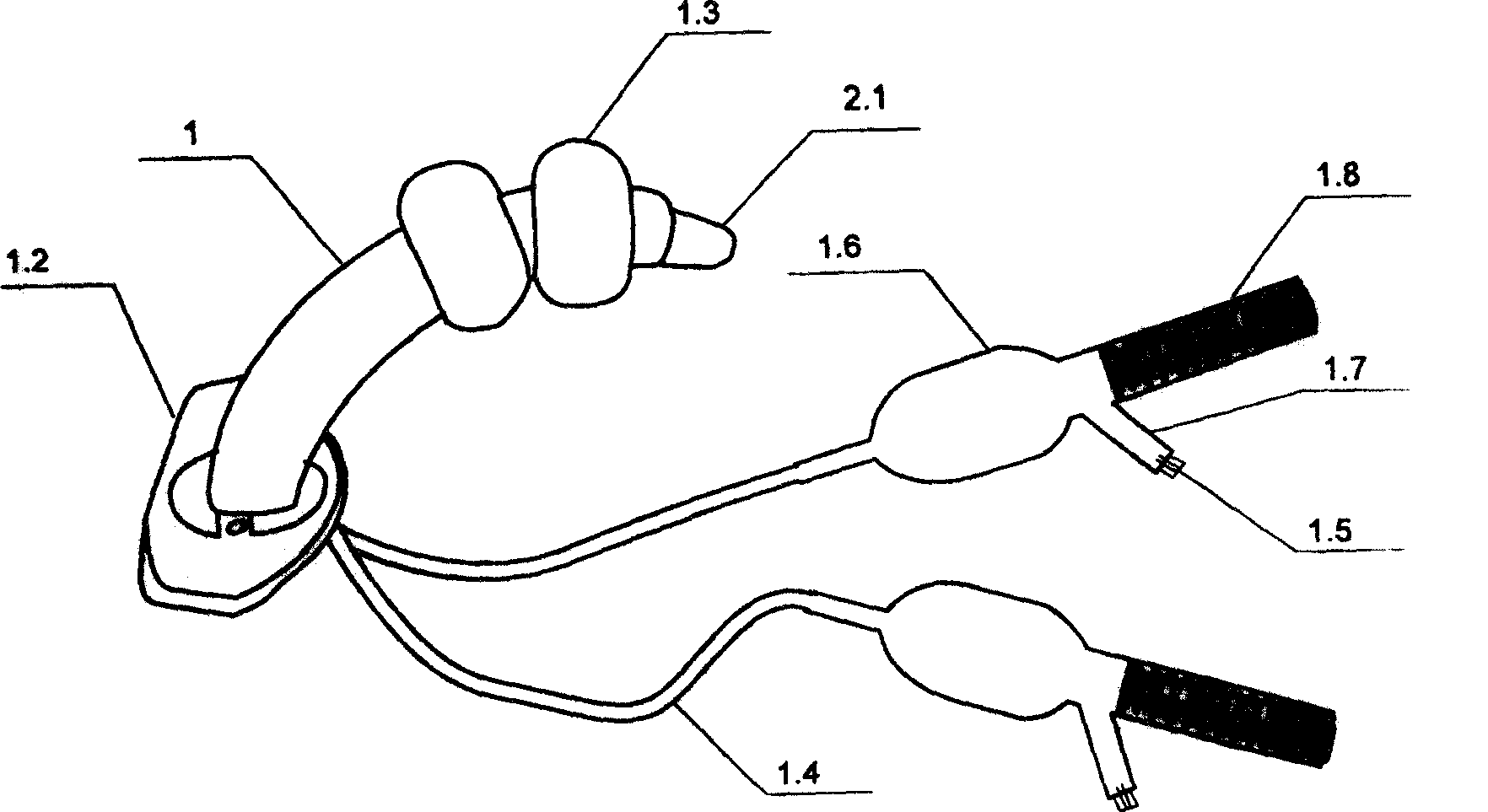

[0018] The present invention comprises two parts, an outer tube 1 and a tube core 2. The outer tube 1.1 of the outer tube is bent in a 120° arc, with a length of 90mm (inner arc 78mm, outer arc 102mm), outer diameter 11.9mm, inner diameter 8mm, and the outer diameter of the airbag after inflation. The diameter is 32mm, the width on both sides is 15mm, and the distance between the two airbags is 5mm. The inflatable indicator balloon is 1.6Φ30mm, and the length of the inflation tube 1.4 is 300mm.

[0019] The head 2.1 of the tube core 2 is conical, the top is blunt, the tail end 2.2 is a square sheet, the length of the tube body 2.3 in the middle matches the sleeve 1.1, the tube core 2 is placed in the outer sleeve, and the head of the tube core 2.1 just extends out of the distal nozzle 1.1.1 of the casing 1.1, and the tube core tail end 2.2 just covers the proximal nozzle 1.1.2 of the casing 1.1.

Embodiment 2

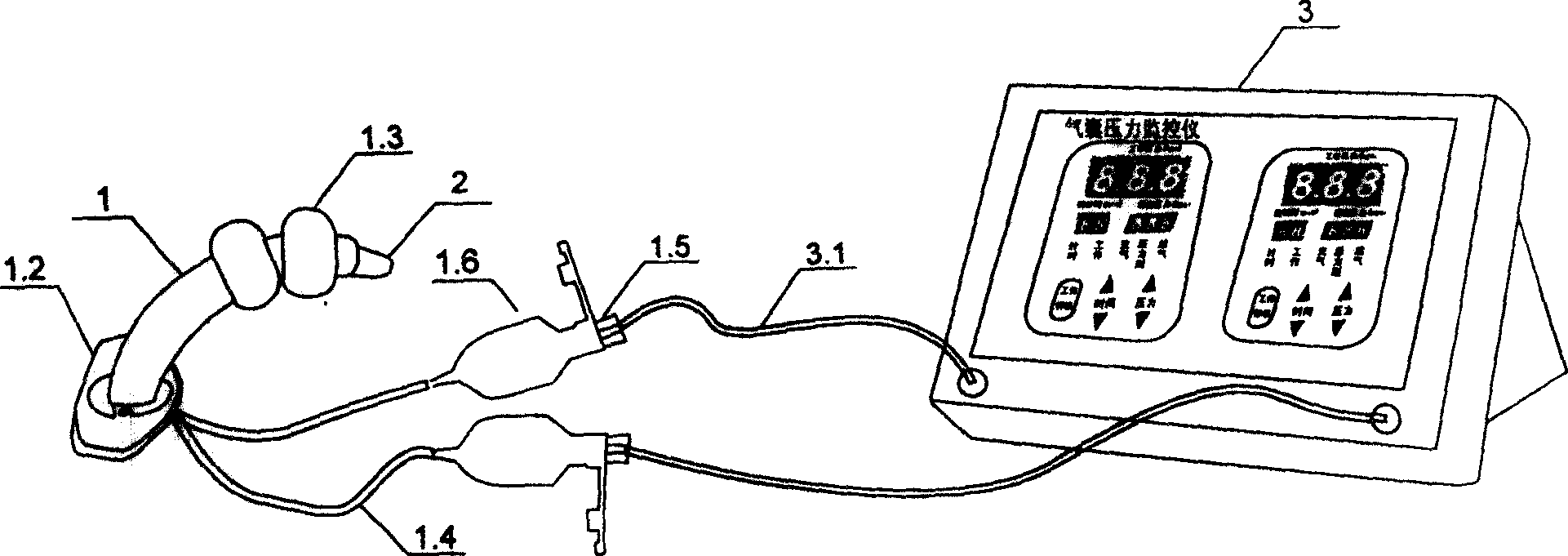

[0021] The inflation valve 1.5 at the air pressure indicating balloon 1.6 end of the present invention is connected with the numerically controlled air bag pressure monitor 3, and all the other are the same as embodiment 1, such as figure 1 shown.

Embodiment 3

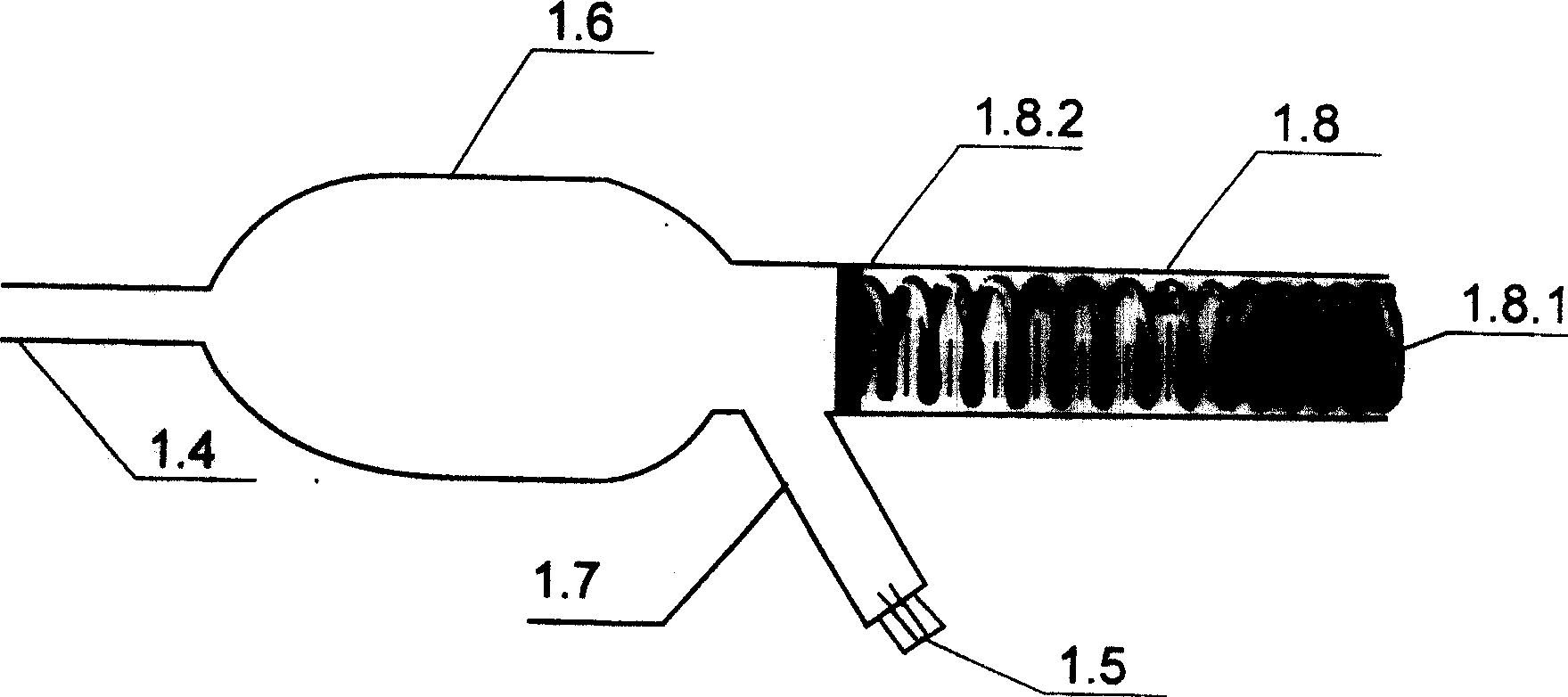

[0022] Embodiment 3. The air pressure indicating balloon 1.6 tail of the present invention is bifurcated into two branch pipes, one branch pipe is provided with the inflation valve pipe 1.7 of the inflation valve 1.5 at the mouth of the pipe, and the other branch pipe is the air bag pressure indicator 1.8 (length 4cm, outer diameter 4mm, inner diameter 3.8mm), the pressure scale (0~30mmHg) is marked on the tube wall of the airbag pressure indicator, and there is a metal spring 1.8. The circular rubber valve 1.8.2 of mm links to each other, and the diameter of this circular rubber valve matches the cavity diameter of the airbag pressure indicator to prevent gas from overflowing, and all the other are the same as embodiment 1, such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com