Image forming apparatus

An image and equipment technology, applied in the field of electrophotography or electrostatic recording system, can solve the problems of reducing productivity and elapsed time, and achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

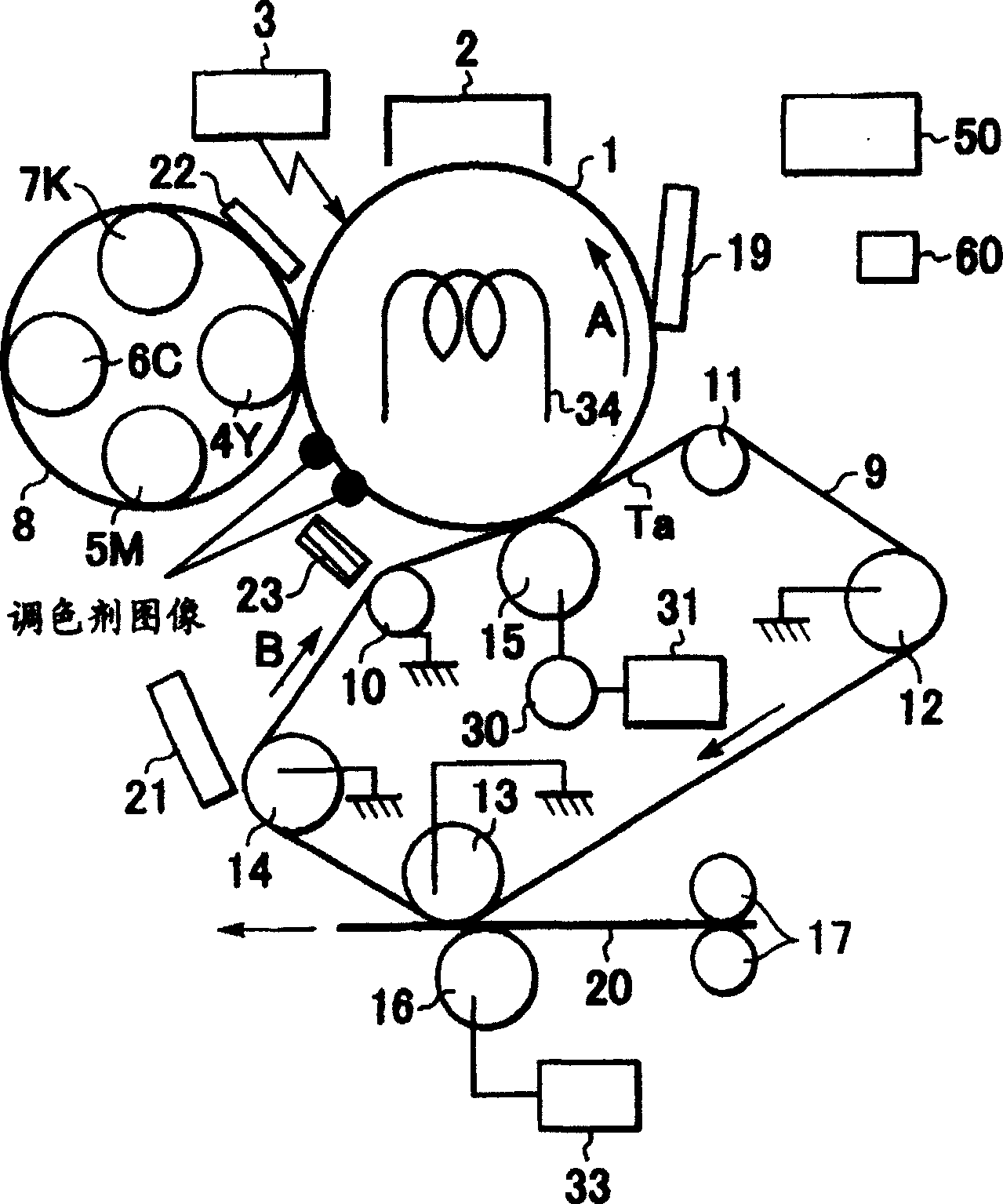

[0047] figure 1 is a schematic block diagram of a color image forming apparatus according to an embodiment of the present invention.

[0048] exist figure 1 , a photosensitive drum 1 (the photosensitive drum 1 being a drum-shaped electrophotographic photoconductor serving as an image carrier) rotates in an arrow A direction. On its surface, an electrostatic latent image is formed by a known electrophotographic process. A charging device or charger 2 is arranged along the rotational direction of the photosensitive drum and an exposure unit 3 or image forming device partially exposes the toner image on the photosensitive drum. Toner colors using Y, M, C, and K colors are used for color images. A yellow (Y) developed image (toner image) is formed from the electrostatic latent image by the developer device 4Y mounted on the rotary developing unit 8 . Under the rotation of the photosensitive drum 1 , the toner image is mainly transferred onto the intermediate transfer belt 9 ...

no. 2 example

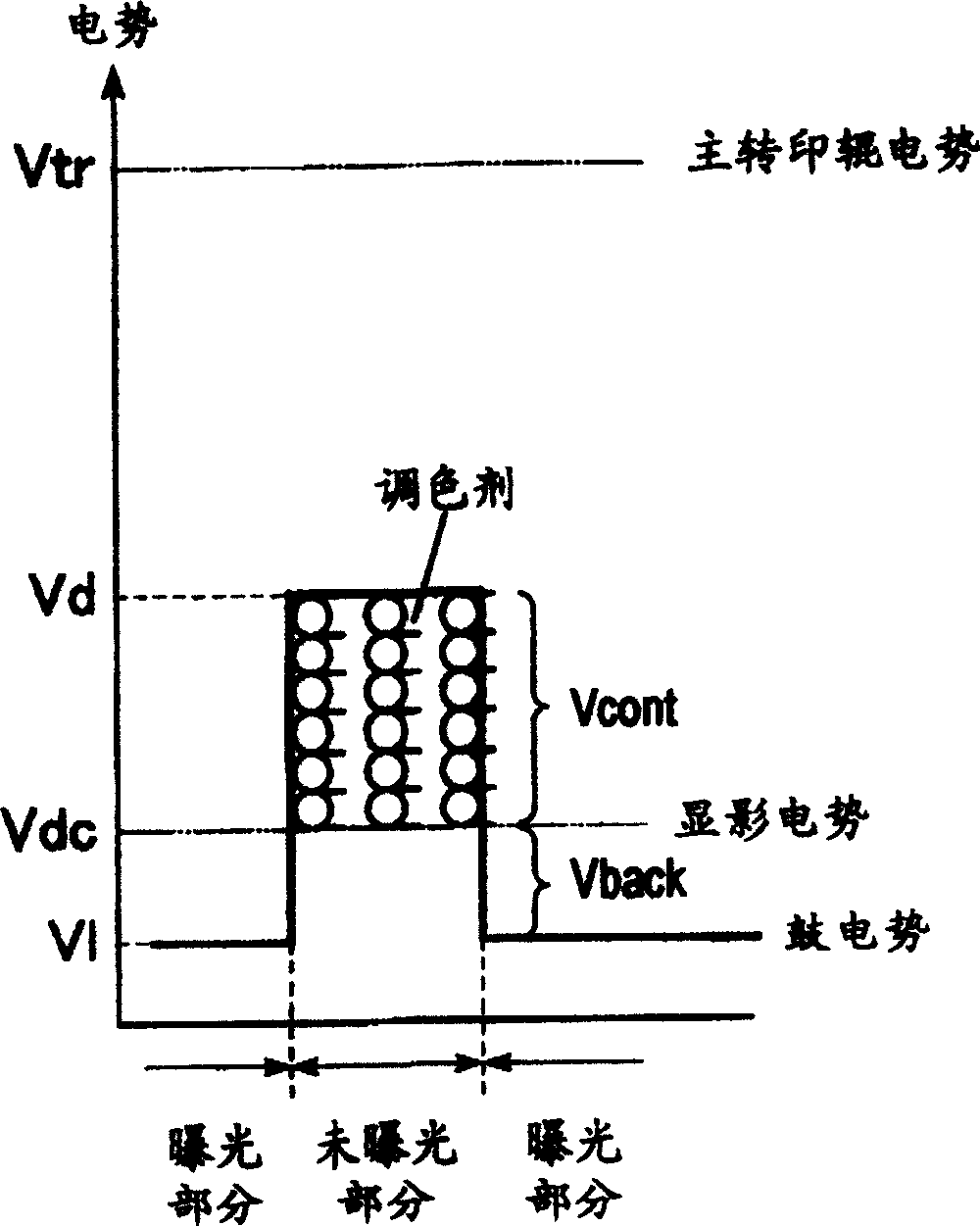

[0080] As in the case of the first embodiment, in the second embodiment, the toners used are all of the negatively charged type, and of the type that makes the photosensitive drum 1 positively charged. Such as figure 2 As shown in , the developing operation is performed by the normal developing method.

[0081] This embodiment differs from the first embodiment only in that temperature and humidity information is used in this embodiment when determining the V1 value for each color.

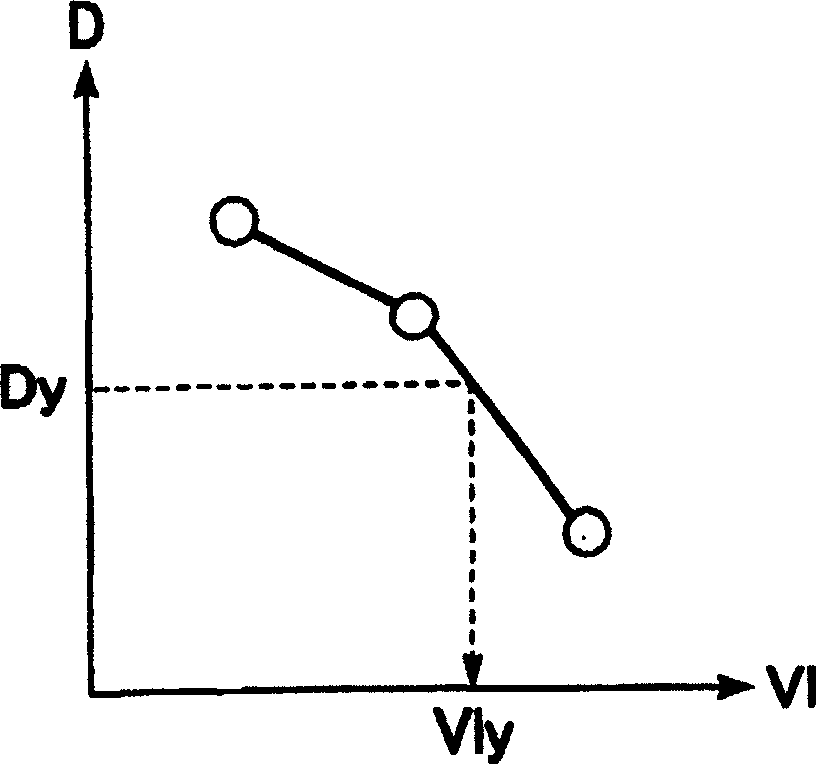

[0082] While the potential detector 22 monitors the surface potential of the photosensitive drum 1, first, the photosensitive drum 1 is uniformly charged to the drum potential Vd by the charger 2, a toner image is developed at this potential, and the exposure unit 3 makes the photosensitive drum without adjustment. The developed area of the toner image is exposed and destaticized to potential V1.

[0083] Such as figure 1 As shown in , in this case, when the developer device 4Y is moved and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com